Carbon steel structural component self-compression electric arc additive manufacturing method

A technology for additive manufacturing and structural parts, applied in the field of additive manufacturing, can solve the problems of large wall thickness of titanium alloy structural parts, decreased mechanical properties of components, complex additive manufacturing methods, etc., and achieves good arc stability and low equipment cost. , the effect of high-precision and high-efficiency additive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

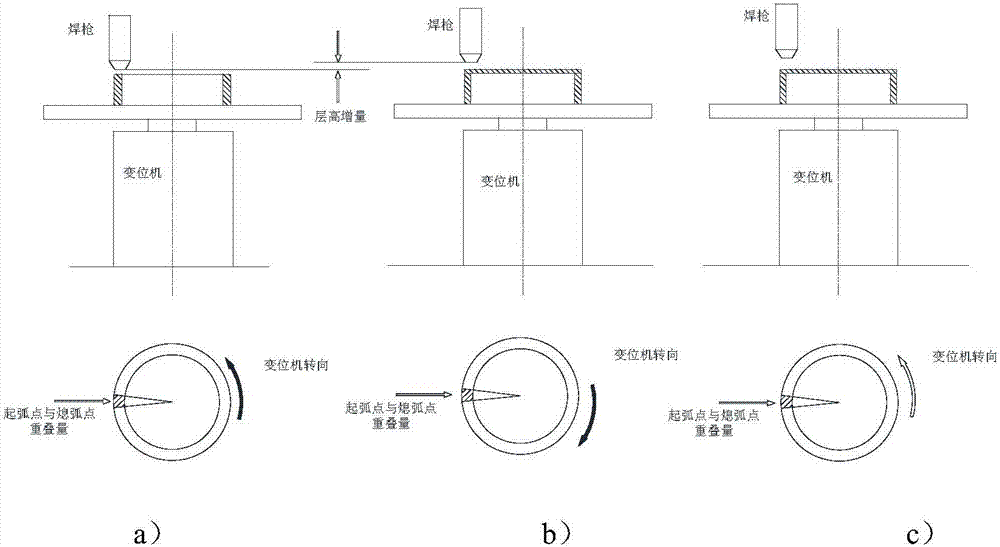

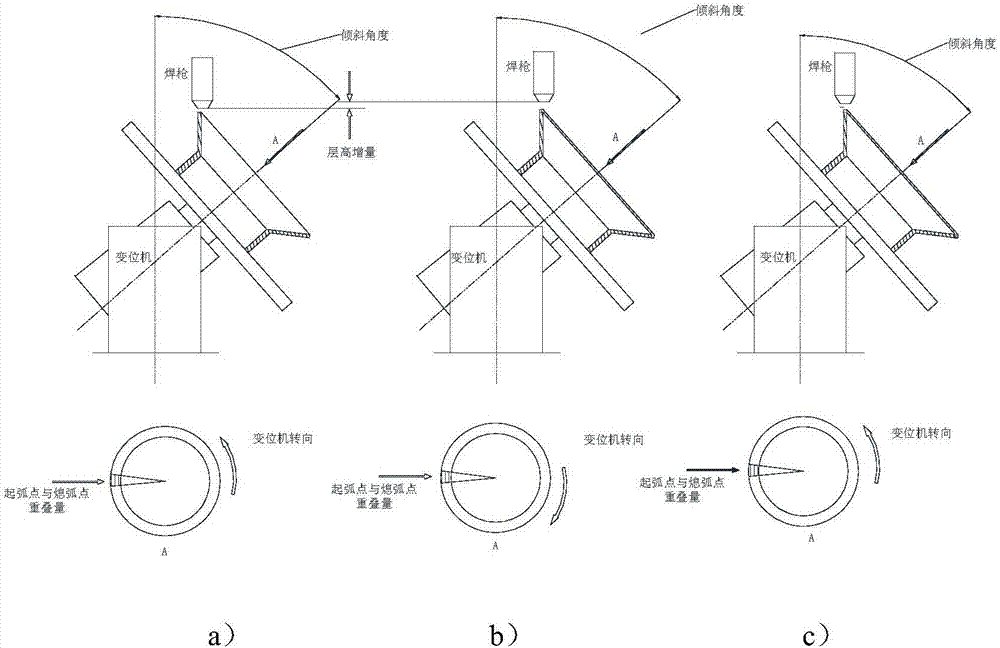

[0025] A self-compression arc additive manufacturing method for carbon steel structural parts according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

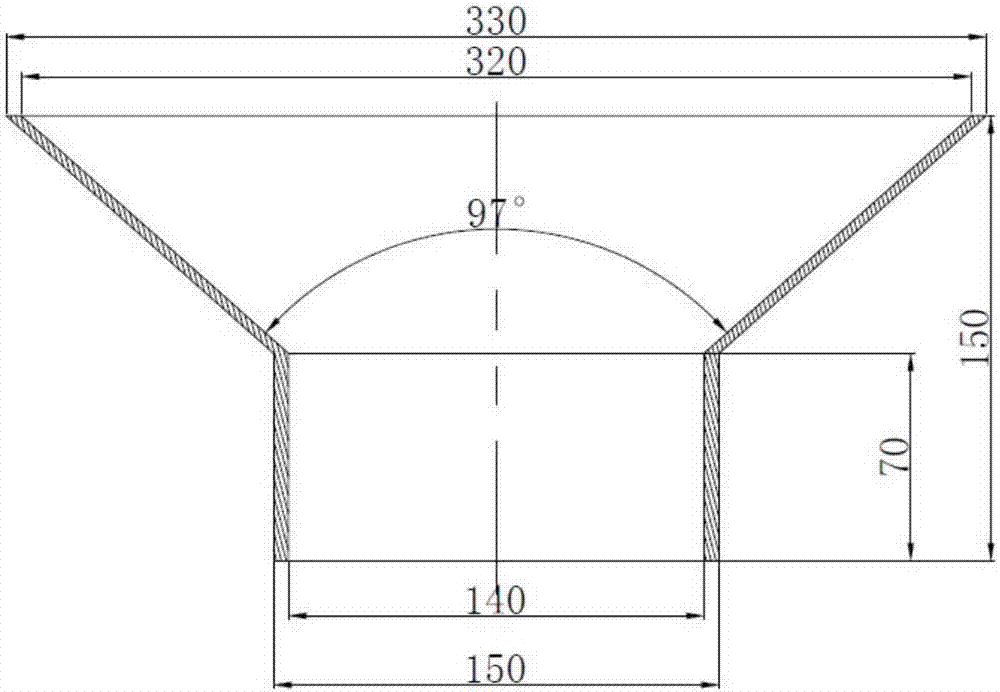

[0026] like image 3 As shown, the carbon steel structural member consists of two parts: a cylindrical shell and a conical shell. Among them, the cylindrical shell part has a height of 70mm and a wall thickness of 5mm, which is composed of 140 layers of stacked metal sheets, each sheet height is 0.35mm; the height of the conical part is 80mm, the wall thickness is 5mm, and the cone angle is 97 °, consisting of 220 layers of stacked metal sheets.

[0027] Process: The stacking current is 120A, the stacking speed is 40cm / min, the wire filling speed is 0.8 / min, the ion gas is 0.8L / min, the protective gas is 15L / min, the wire material is Ф1mm H08Mn2Si, and the stacking layer width is 5mm .

[0028] Equipment used: arc additive manufacturing platfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com