Auto-rotating sprayer

A self-rotating and rotating head technology, applied in the direction of spraying device, spraying device with movable outlet, etc., can solve the problem of not having to adjust the rotation speed and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

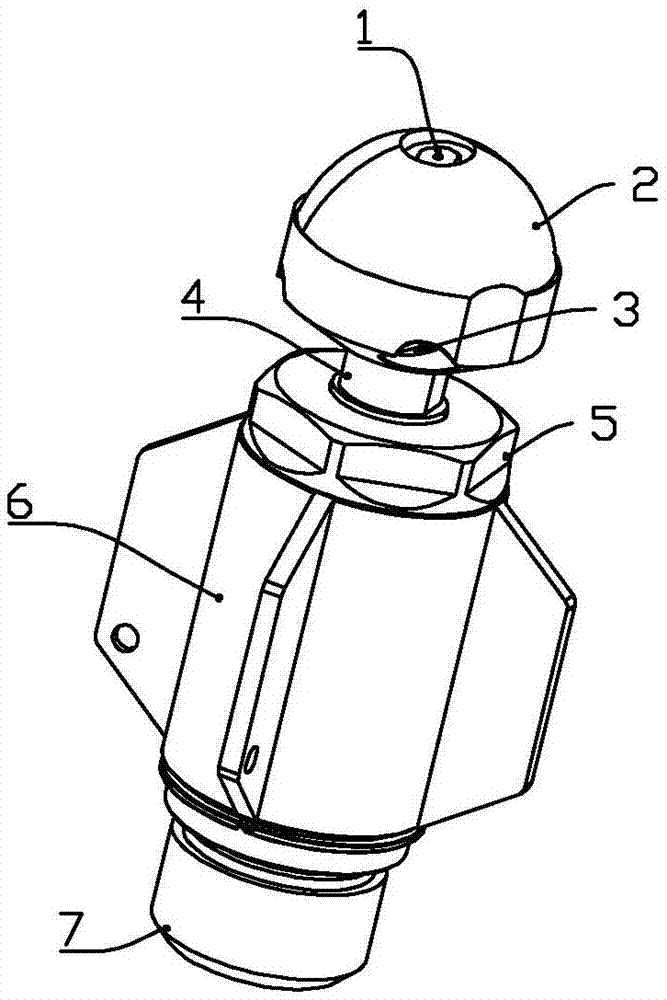

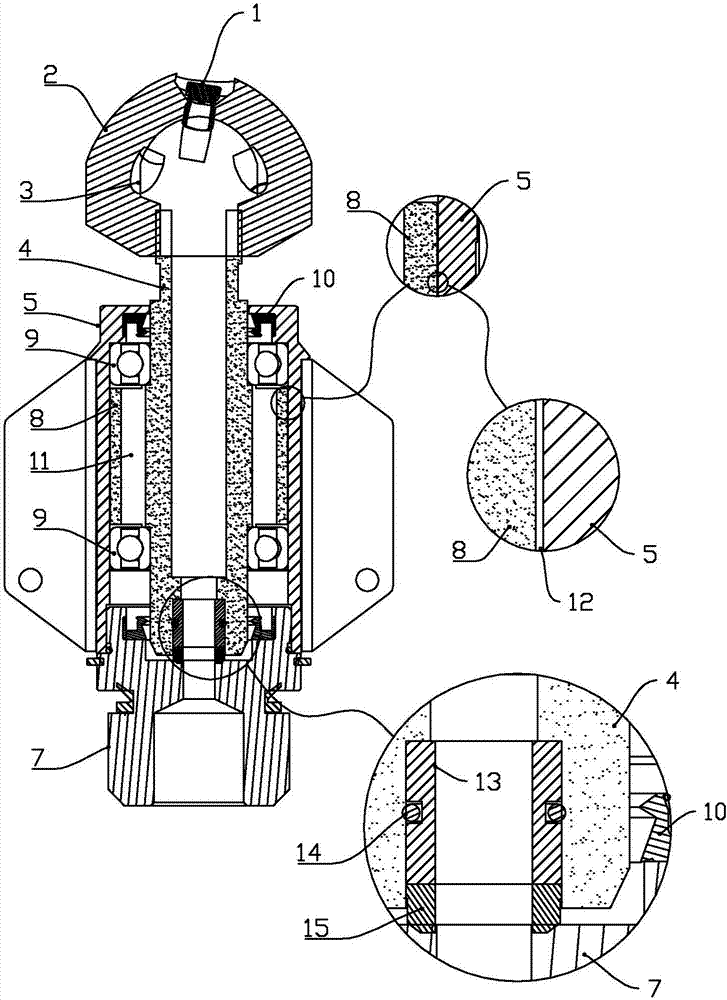

[0025] The present invention will be further described below with specific embodiments in conjunction with the drawings, see Figure 1-4 :

[0026] A self-rotating sprinkler, see in detail image 3 , Including a hollow rotating shaft 4, the upper end of the rotating shaft 4 protrudes from the top end surface of the housing 5 and is connected to the rotating head 2, the lower part of the housing 5 is opened and a connecting nut 7 is screwed; a sealing groove is also opened on the lower end surface of the rotating shaft 4, An annular flange is arranged at the bottom of the sealing groove, and the inner hole of the rotating shaft 4 is connected with the sealing groove through the inner hole of the annular flange; an annular copper seal 13 is embedded in the sealing groove, and a sealing ring 14 is provided on the outer periphery of the sealing 13 to seal An elastic sealing seat 15 is pressed between the outer end surface of the member 13 and the connecting nut 7. The sealing seat 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com