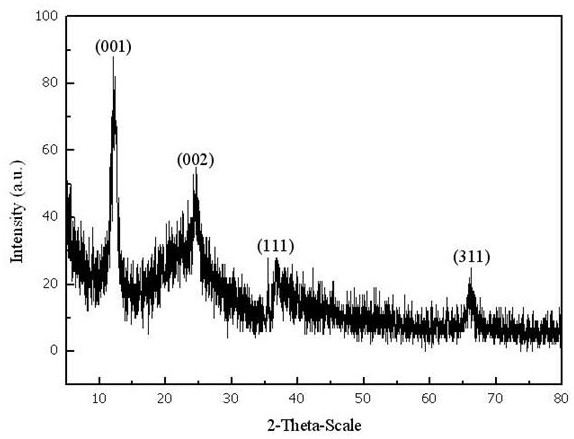

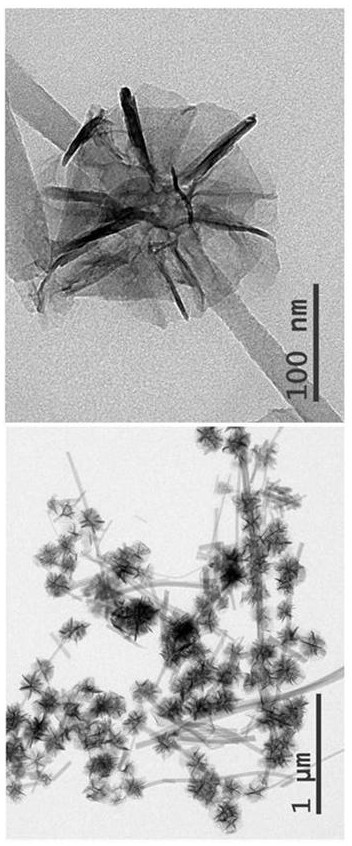

A kind of composite catalyst of manganese dioxide nanoflower and silica nanofiber and preparation method thereof

A composite catalyst, nanofiber technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of limited surface area for manganese growth and support, and achieve excellent catalysis Activation, enhanced dispersion, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 4g of silica nanofibers (the nanofibers have a diameter of 30-60 nm and a length of 5-20 μm), and completely disperse them in 1L of water under vigorous stirring to form a uniform primary suspension. Weigh 7.40 g of potassium permanganate and 3.20 g of sodium persulfate (the concentration of sodium persulfate is 13.4 mmol / L), add them into the above-mentioned primary suspension under stirring conditions, and keep stirring for 10 min to completely dissolve to obtain secondary suspension. The above-mentioned secondary suspension was transferred into an autoclave for hydrothermal reaction at 90° C. for 4 hours. After the reaction was over, it was naturally cooled to room temperature. The suspension after the hydrothermal reaction was separated from solid to liquid, and the separated solid product was washed with water three times, and dried in a drying oven at a temperature of 80°C to constant weight to obtain the final manganese dioxide nanoflowers and silica nanof...

Embodiment 2

[0031]Weigh 5g of silica nanofibers (the nanofibers have a diameter of 20-50 nm and a length of 3-10 μm), and completely disperse them in 1L of water under vigorous stirring to form a uniform primary suspension. Weigh 4.3 g of potassium permanganate and 2.70 g of potassium persulfate (concentration of potassium persulfate is 10 mmol / L), add them into the above-mentioned primary suspension under stirring, and keep stirring for 10 min to completely dissolve to obtain secondary suspension. The above-mentioned secondary suspension was transferred into an autoclave for hydrothermal reaction at 95° C. for 4.5 hours. After the reaction was over, it was naturally cooled to room temperature. The suspension after the hydrothermal reaction was separated from solid to liquid, and the separated solid product was washed with water three times, and dried in a drying oven at a temperature of 80°C to constant weight to obtain the final manganese dioxide nanoflowers and silica nanofibers Comp...

Embodiment 3

[0033] Weigh 5g of silica nanofibers (the nanofibers have a diameter of 40-100 nm and a length of 10-20 μm), and completely disperse them in 1L of water under vigorous stirring to form a uniform primary suspension. Weigh 6.90 g of potassium permanganate and 3.80 g of ammonium persulfate (the concentration of ammonium persulfate is 16.7 mmol / L), add them to the above primary suspension under stirring, and keep stirring for 10 min to completely dissolve to obtain secondary suspension. The above-mentioned secondary suspension was transferred into an autoclave for hydrothermal reaction at 85° C. for 5 hours. After the reaction was over, it was naturally cooled to room temperature. The suspension after the hydrothermal reaction was separated from solid to liquid, and the separated solid product was washed with water three times, and dried in a drying oven at a temperature of 80°C to constant weight to obtain the final manganese dioxide nanoflowers and silica nanofibers Composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com