Substrate leveling equipment and semiconductor fabrication method employing same

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as substrate deformation, substrate clamping and fixing, and substrate warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be exemplified below in detail with accompanying drawings.

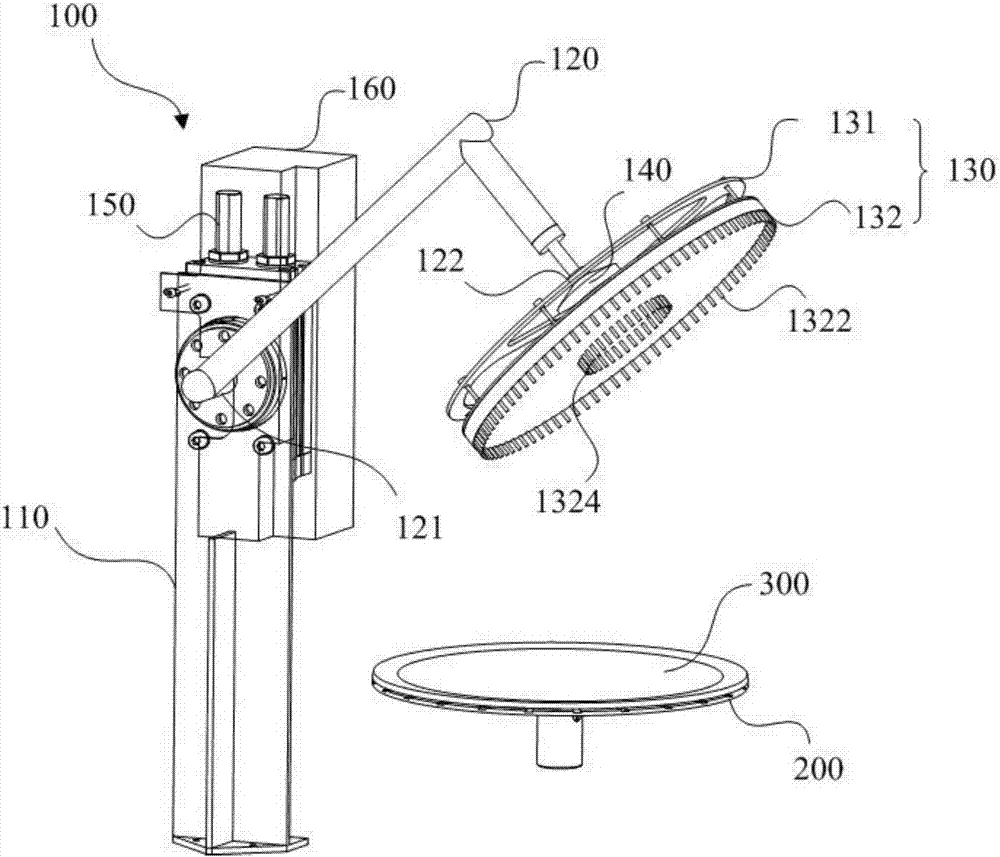

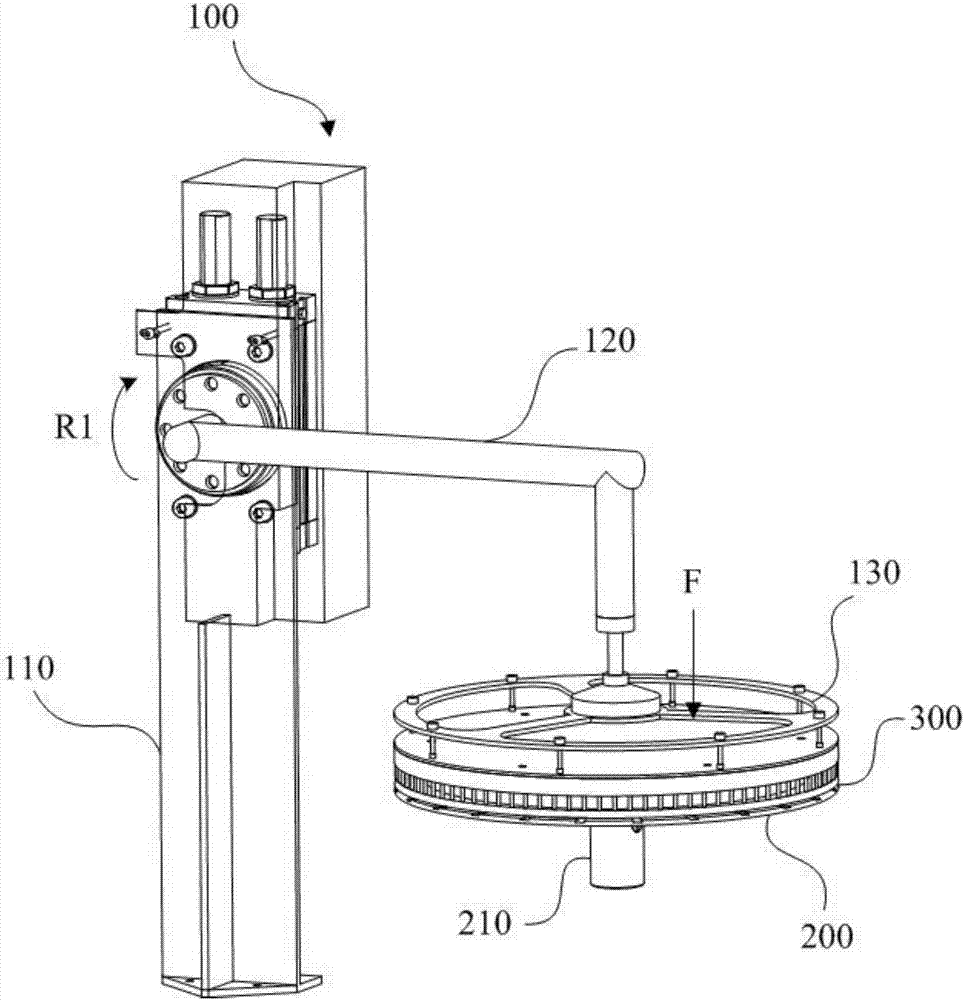

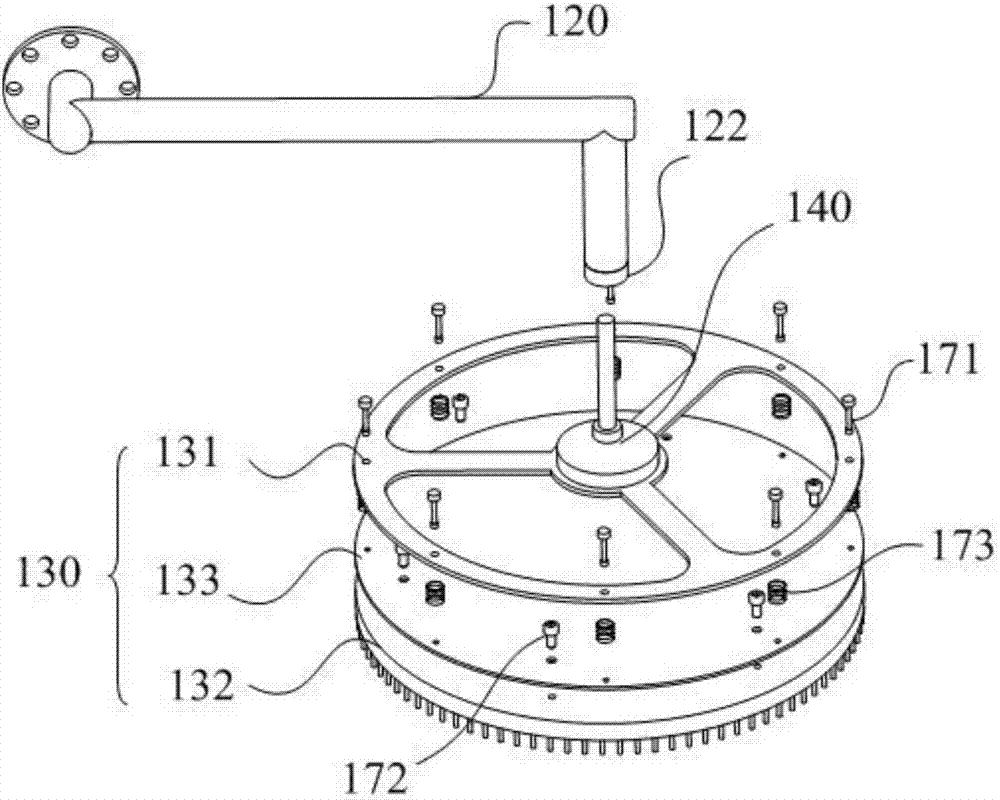

[0023] Please refer to figure 1 , which shows a schematic perspective view of a substrate flattening device 100 according to the first preferred embodiment of the present invention. The substrate flattening apparatus 100 includes a base 110 , a rotating arm 120 and a disc assembly 130 . One end of the base 110 can be fixed on the ground or erected on a transport mechanism, and the substrate flattening device 100 can be transported to a working position through the transport mechanism. Such as figure 1 As shown, the rotating arm 120 is roughly in an "L" shape and has a first end 121 and a second end 122 . The first end 121 of the rotating arm 120 is rotatably connected to the base 110 through a rotating power device 150 , and the second end 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com