Silanol-based bicomponent waterborne polyurethane wood adhesive and preparation method thereof

A technology of water-based polyurethane and wood adhesives, which is applied in polyurea/polyurethane adhesives, unsaturated alcohol copolymer adhesives, adhesives, etc., can solve problems affecting the health of users in the environment, and achieve improvement and prolongation of the board-making process. Effect of pot life, enhanced wet bond strength and resistance to water, weathering and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

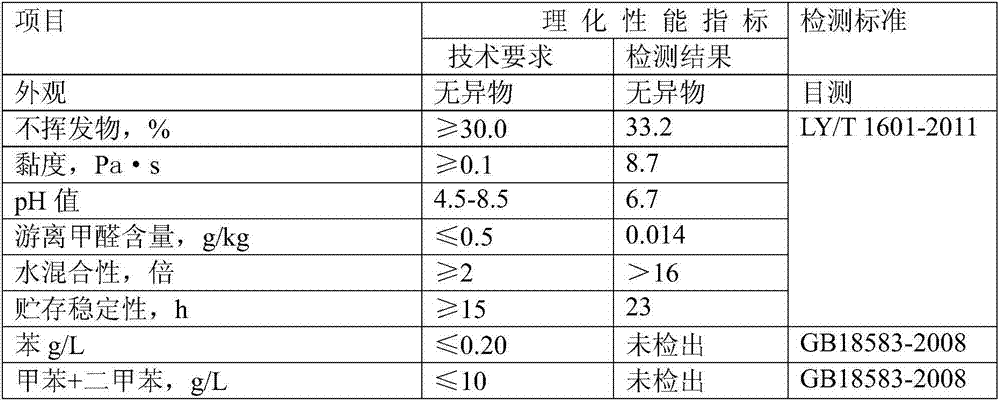

Embodiment 1

[0067] 1. Adhesive formula:

[0068] The main agent is made of the following components by weight ratio:

[0069] 9 parts of polyvinyl alcohol;

[0070] 11 parts of compound polyol (made by mixing soybean oil polyol, polyether polyol and dibutyl phthalate in a weight ratio of 10:1:40);

[0071] 15 parts of silica sol;

[0072] 0.4 parts of propylene glycol;

[0073] 0.05 part of polyacrylamide;

[0074] 65 parts of water;

[0075] 0.05 part of surfactant (sodium dodecylbenzenesulfonate);

[0076] 0.08 part of defoamer (n-butanol);

[0077] Preservative (isothiazolinone) 0 parts;

[0078] 15 parts of filler (calcium carbonate);

[0079] The crosslinking agent is made of the following components in weight ratio:

[0080] 7 parts castor oil;

[0081] 28 parts of polyol benzoate;

[0082] 65 parts of isocyanate (polyphenyl polymethylene polyisocyanate (polymeric MDI)).

[0083] The weight ratio of main agent and crosslinking agent is 100:10.

[0084] 2. Preparation me...

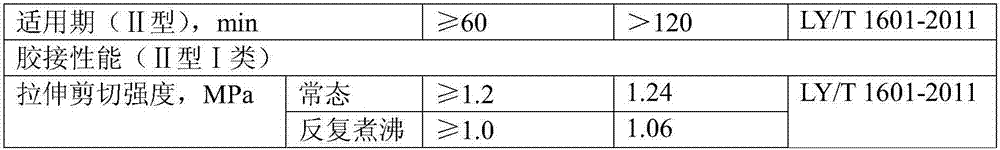

Embodiment 2

[0094] 1. Adhesive formula:

[0095] The main agent is made of the following components by weight ratio:

[0096] 10 parts of polyvinyl alcohol;

[0097] 10 parts of complex polyols (made from 14 parts of soybean oil polyols, 4 parts of polyether polyols, and 50 parts of dioctyl phthalate);

[0098] 25 parts of silica sol;

[0099] 0.35 parts of propylene glycol;

[0100] 0.06 part of polyacrylamide;

[0101] 55 parts of water;

[0102] Surfactant (sodium dodecylbenzenesulfonate) 0.08 part;

[0103] 0.10 part of defoamer (tributyl phosphate);

[0104] 0.05 part of antiseptic (isothiazolinone);

[0105] Filler (talcum powder) 8 parts;

[0106] The crosslinking agent is made of the following components in weight ratio:

[0107] 5 parts castor oil;

[0108] 20 parts of polyol benzoate;

[0109] 75 parts of isocyanate (polyphenyl polymethylene polyisocyanate (polymeric MDI)).

[0110] The weight ratio of main agent and crosslinking agent is 100:6.

[0111] 2. Preparat...

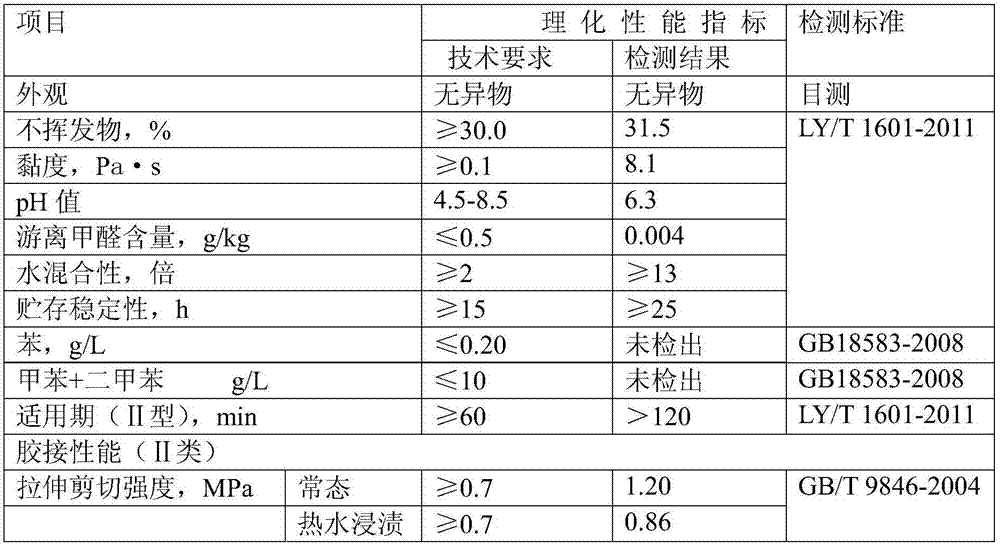

Embodiment 3

[0120] 1. Adhesive formula:

[0121] The main agent is made of the following components by weight ratio:

[0122] 15 parts of polyvinyl alcohol;

[0123] 9 parts of composite polyol (obtained by mixing 15 parts of soybean oil polyol, 2 parts of polyether polyol, 30 parts of dibutyl phthalate and 30 parts of dioctyl phthalate respectively by weight);

[0124] 18 parts of silica sol;

[0125] 0.3 parts of propylene glycol;

[0126] 0.04 parts of polyacrylamide;

[0127] 60 parts of water;

[0128] 0.2 part of surfactant (sodium dodecylbenzenesulfonate);

[0129] 0 parts of defoamer (n-butanol);

[0130] 0.08 part of antiseptic (isothiazolinone);

[0131] 12 parts of filler (composed of kaolin and talc in a weight ratio of 2:1);

[0132] The crosslinking agent is made of the following components in weight ratio:

[0133] Vegetable oil (castor oil) 6 parts;

[0134] 30 parts of polyol benzoate;

[0135]72 parts of isocyanate (diphenylmethane diisocyanate (pure MDI)).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com