Method for synthesizing siloxane modified epoxy resin and water-based anti-corrosion coating

A technology of siloxane modification and epoxy resin, used in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of insufficient cross-linking, low solid content of products, low solid content, etc., and achieve optimal waterproofing. Excellent performance, gloss retention, color retention, aging resistance, weather resistance, corrosion resistance, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] 1. Preparation of siloxane hydrolyzate (measured in parts by mass)

[0059] ① Preparation of alcohol-acid-water solution: Weigh 80-85 parts of isopropanol, 5-10 parts of oxalic acid (COOCCOOH, content ≥ 98.0%), 5-10 parts of purified water, mix and dissolve evenly for later use.

[0060] ② Siloxane hydrolysis reaction: Weigh 65-70 parts of methyltriethoxysiloxane (MTES), octyltriethoxysiloxane (THES) or isooctyltriethoxysiloxane ( IYES), add 25 to 35 parts of alcohol-acid-water solution dropwise in the reaction kettle under stirring, and react slowly at room temperature for 3 to 5 hours. After the solution is completely clear and transparent, place it for 24 hours for later use.

[0061] The hydrolysis reaction process is as follows:

[0062]

[0063]

[0064]

[0065] Wherein, R is methyl, octyl, isooctyl, etc.;

[0066] ③Replacement phase inversion: Determine the solid content of the siloxane hydrolyzate according to the GB / T 1725 method, and the balance is...

Embodiment 1

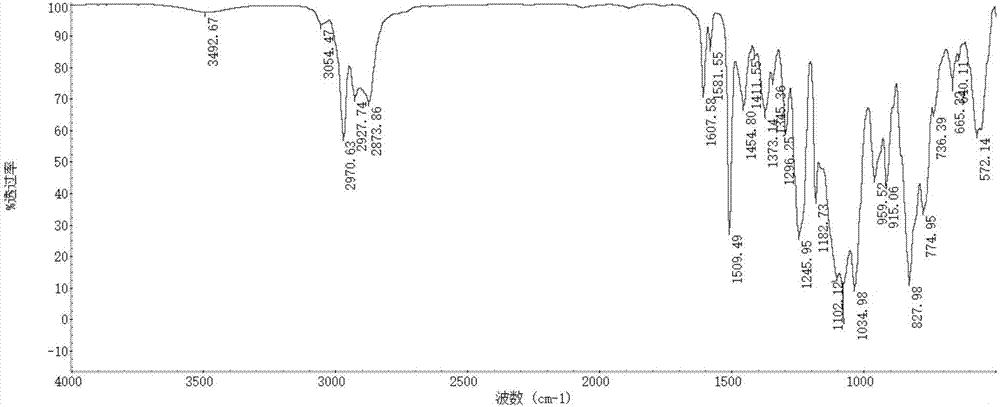

[0100] Embodiment one MTES modified epoxy resin

[0101]Weigh 85 parts of isopropanol, 10 parts of oxalic acid (COOCCOOH, content ≥ 98.0%), and 5 parts of pure water, mix and dissolve evenly to make an aqueous acidic hydrolysis catalyst solution; then take 30 parts of alcohol-acid-water solution, and in the reaction Add it dropwise to 70 parts of MTES in the stirring state, react slowly at room temperature for 3-5 hours, wait for the solution to be completely clear and transparent, and let it stand for 24 hours; measure the solid content of the siloxane hydrolyzate according to the GB / T 1725 method, and the remaining The amount is water and alcohol solution, add the same amount of glycidyl methacrylate MTES, under vacuum at 120°C, extract the alcohol and water, complete the replacement and phase inversion, and obtain anhydrous and alcohol-free hydrolyzed siloxane; take low viscosity The (E-51 or 128) epoxy resin and hydrolyzed siloxane are mixed in the reactor at a molar ratio...

Embodiment 2

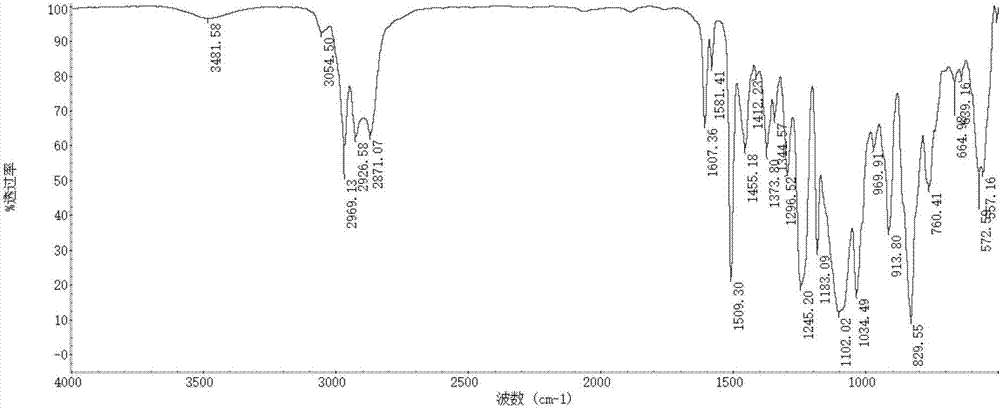

[0102] Embodiment two THES or IYES modified epoxy resin

[0103] In this embodiment, the MTES in the first embodiment is replaced by THES or IYES, and the experimental method is the same, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com