Omnipotent triple-head stamping machine

A stamping machine, all-round technology, applied in printing, stamping and other directions, can solve the problems of unclear seal, insufficient and complete printing, affecting the efficiency of printing, etc. Print quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

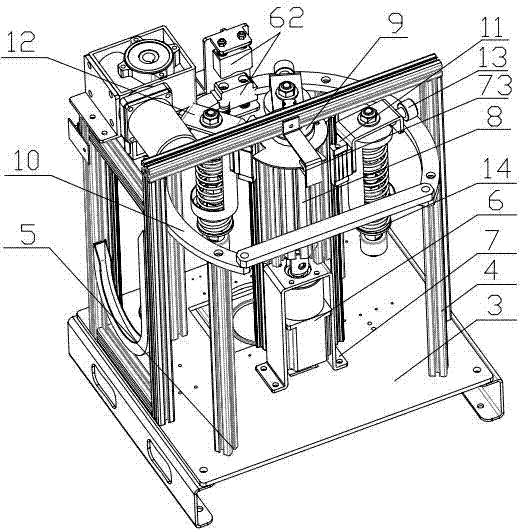

[0047] An all-round three-head stamping machine, including a head 1 and a base 2, a housing is arranged inside the head 1, as attached figure 1 As shown, the housing is provided with a fixed frame, and the fixed frame includes a base plate 2, an inverted U-shaped frame 4 and a plurality of vertical frames 5, and the inverted U-shaped frame 4 and the vertical frames 5 are fixed on the base plate 3 Above, the housing is provided with a control unit, a rotating mechanism, a double ball joint spring arm 14, an ink cartridge mechanism, a laser indicator mechanism and a lifting mechanism, and the ink ink cartridge mechanism and the laser indicator mechanism are arranged below the bottom plate 3, And cooperate with the rotating mechanism, the double ball joint spring arm and the lifting mechanism arranged on the top of the base plate 3 to complete the stamping operation by receiving the driving signal sent by the control unit.

[0048] as attached figure 1 As shown, the rotating mec...

Embodiment 2

[0061] Different from Embodiment 1, the number of the lifting linear guides arranged on the hexagonal rotating column 8 can be set to three groups, and the central angle between two adjacent groups of lifting linear guides is 60°, and each group of lifting linear guides The quantity and the quantity of spring arm installation rack 12 and double ball joint spring arm 14 are adapted, and the stamp holder 26 of every cover double ball joint spring arm 14 is installed with the seal of different functions respectively, in the face of a document needs Affix a plurality of seals, the CPU on the control unit issues an instruction, designates the first double ball joint spring arm 14 that will perform the stamping operation and the seal carried on the stamp holder 26 to rotate to the printing position for printing, after the printing is completed , and then perform the next stamping operation, no need to replace the stamp, and achieve high efficiency of the stamping operation.

Embodiment 3

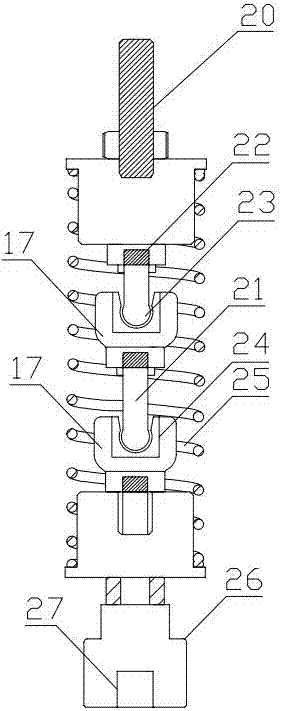

[0063] The difference from Embodiments 1 and 2 is that there are two swing joints 17, the connecting screw 22 is threadedly connected to the connection groove provided at the bottom of one of the swing joints 17, and the ball head 23 connected with the pull rod 21 is connected with the The ball hinge seat 24 that is provided with in another swing joint 17 cooperates to rotate; The chapter head matches the slope formed by the thicker document, which ensures the integrity and clarity of the seam stamp after stamping, and improves the printing quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com