Bamboo split weaving machine

A technology of weaving machines and bamboo strips, applied in mechanical equipment, sugarcane machining, etc., can solve the problems of poor efficiency, difficulty in guaranteeing the quality of finished products, and slow speed, and achieve the effects of stable and reliable quality, high speed, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

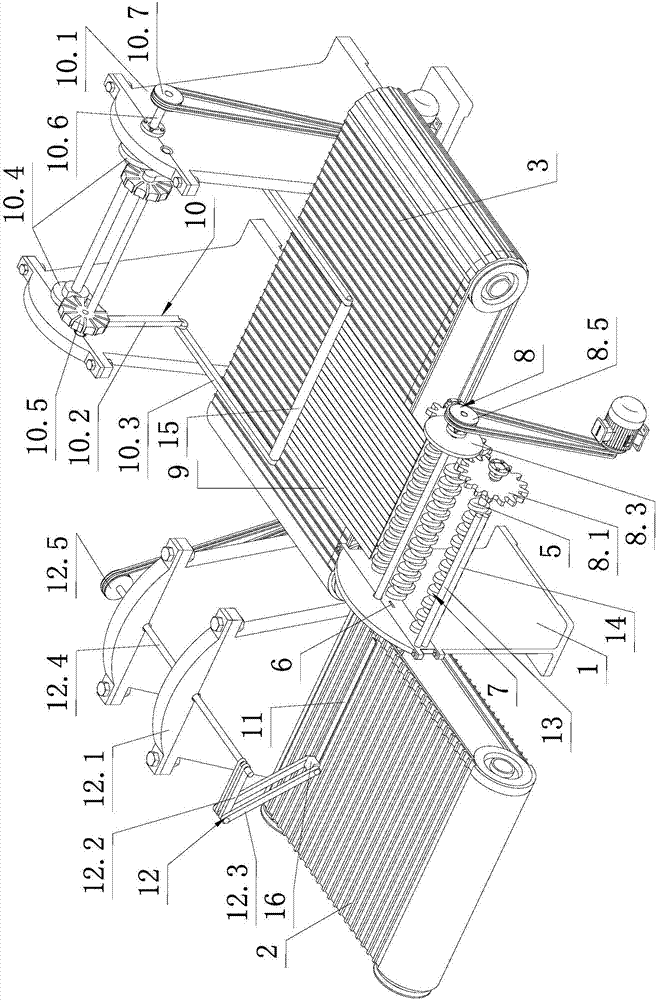

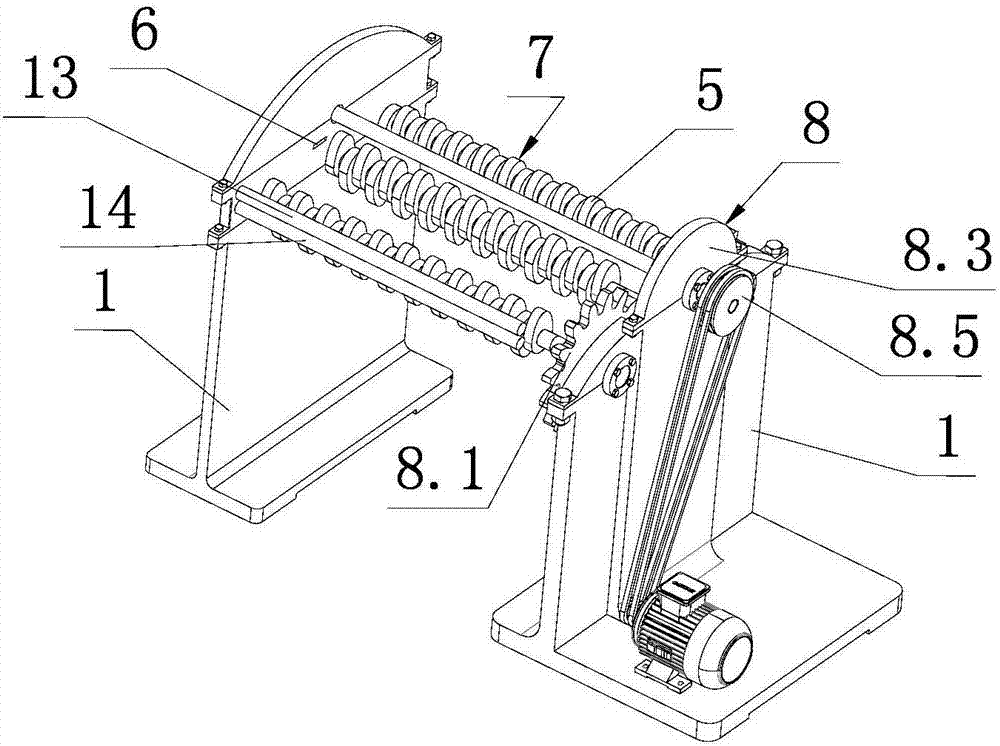

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the bamboo strip weaving machine of the present invention comprises a wheel frame 1, a warp feed belt 2 and a weft feed belt 3, and the wheel frame 1 is two left and right symmetrical.

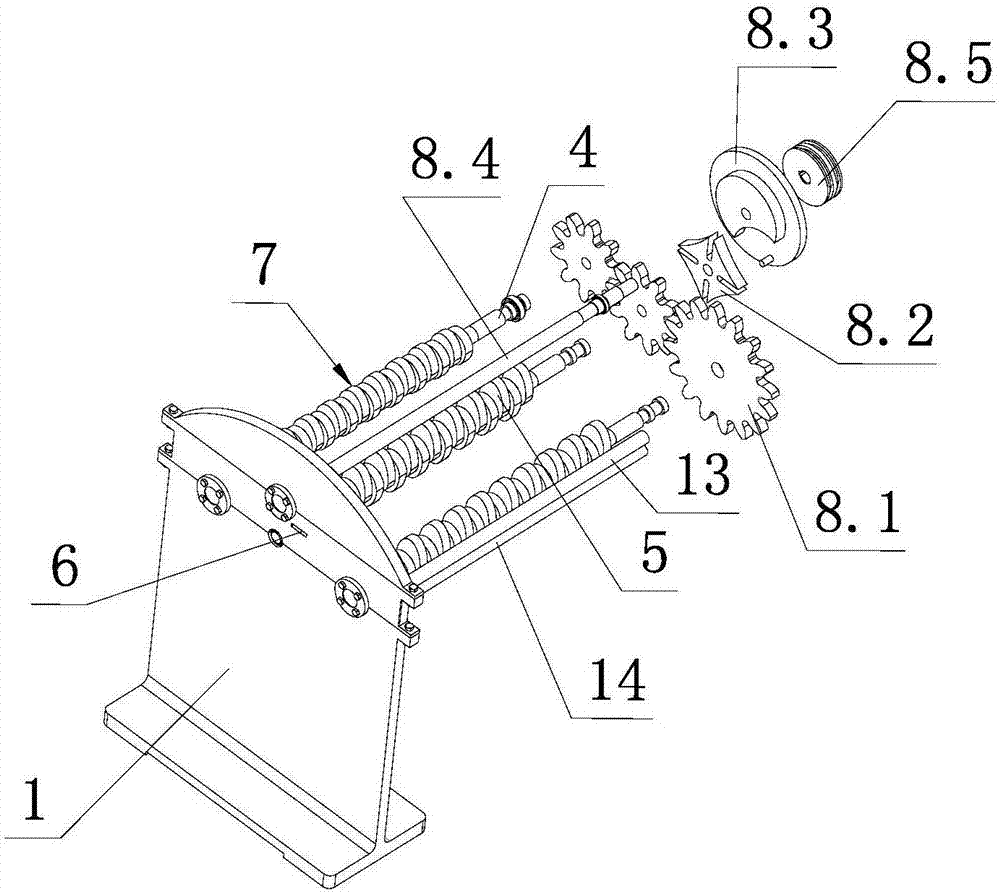

[0021] In this embodiment, three wheel axles 4 are rotatably installed between the left and right wheel frames 1 , and more wheel axles 4 can be installed of course. A plurality of cams 5 are fixed on each wheel shaft 4, and one end of each cam 5 protrudes, while the other three directions are circular arcs that do not protrude. The protruding parts of every two adjacent cams 5 on the same axle 4 are facing oppositely, and the protruding parts of the two cams 5 with the same serial number on two adjacent axles 4 are also facing oppositely. All the cams 5 on all the wheel shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com