Laser cleaning head

A laser cleaning and pulsed laser technology, applied in the field of laser cleaning head, can solve the problems of unsatisfactory cleaning effect, narrow cleaning range, spot surface cleaning method affecting laser cleaning efficiency, etc., and achieve simple structure, large cleaning range, increased The effect of large cleaning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

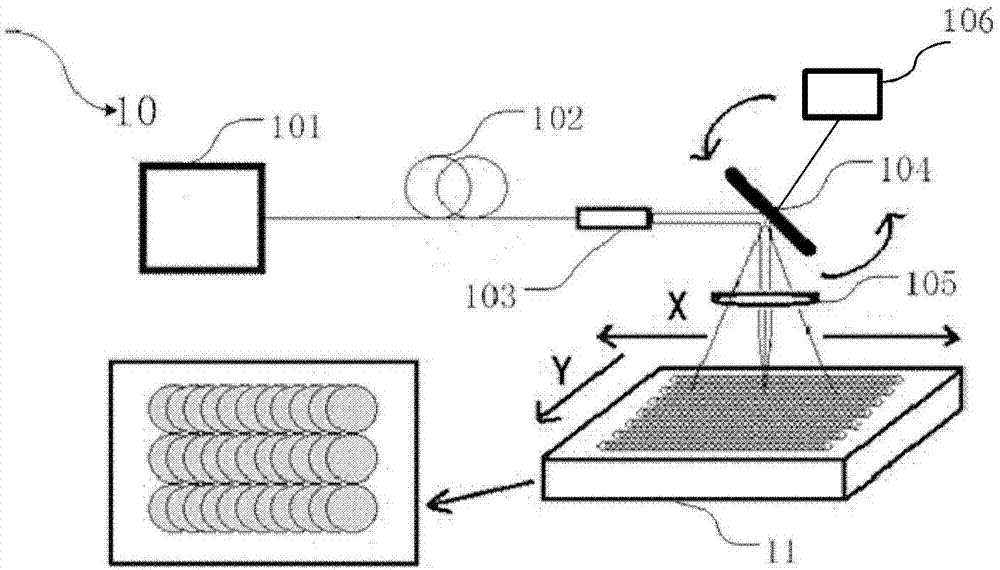

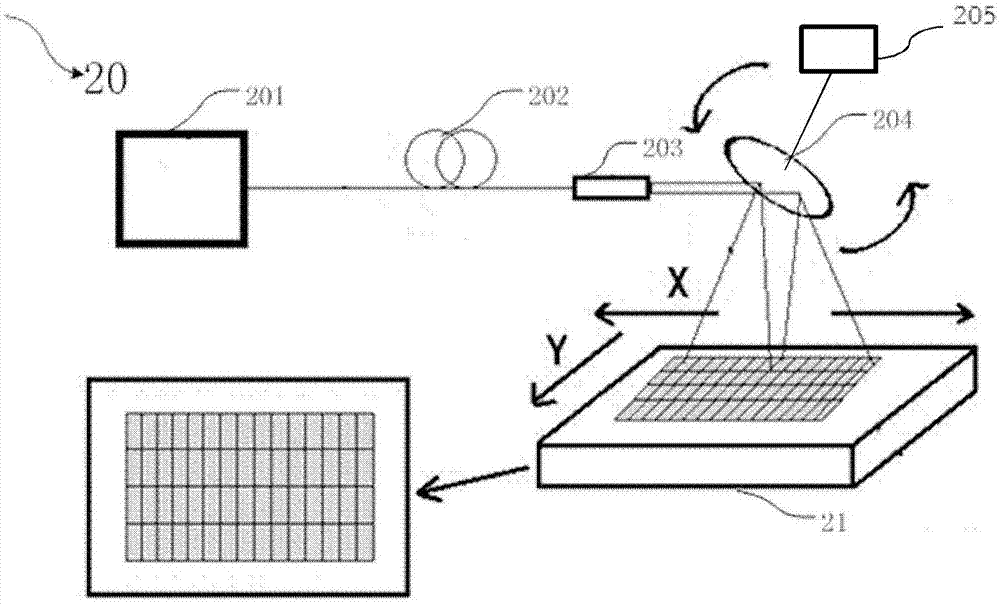

[0040] see figure 2 , the present embodiment proposes a high-efficiency laser cleaning processing head 20, including;

[0041] High-power pulsed laser 201, used to output pulsed high-power laser beam; the beam output power is 800W;

[0042] The energy transmission fiber 202 is used to transmit the high-power laser beam output by the high-power pulse laser to the tunable focusing beam reflector 204; the diameter of the fiber is 400 μm;

[0043] Laser collimator 203; used to perform beam shaping on the high-power laser beam output by the energy transmission fiber 202 to form a rectangular distributed beam;

[0044] Tunable focusing beam reflector 204; used to focus the high-power beam to form a linear beam, and simultaneously used to reflect the high-power laser beam to the surface of the laser cleaning sample 21, which is connected to the frequency adjustment device 205 to form a certain angle with the swing, the swing angle is between 36° and 58°.

[0045] Wherein the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com