A catalyst supported by two-component hybrid particles and its preparation method

A technology of hybrid particles and catalysts, which is applied in the preparation of organic compounds, catalysts for physical/chemical processes, hydrogenation preparation, etc. It can solve the problems of activity limitation, low surface area of inorganic carrier, and weak loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] According to a preferred embodiment of the present invention, the hybrid monomer is a monomer containing inorganic elements, or a mixture of monomers containing inorganic elements and other monomers.

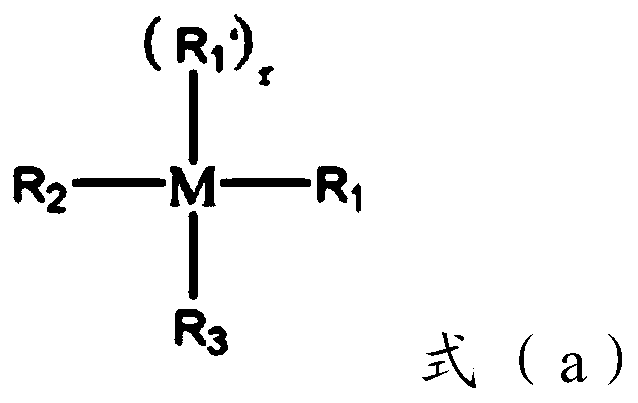

[0043] In a further preferred embodiment, the hybrid monomer is a monomer represented by formula (a) or a monomer represented by formula (a) with an amide group, a hydroxyl group, a carbonyl group, a phenyl group, an alkoxy group and / or or mixtures of alkyl monomers.

[0044]

[0045] According to a preferred embodiment of the present invention, in formula (a):

[0046] (1) M is selected from Fe, Si, Ti, Mg, Zr, B or Al, preferably selected from Fe, Si, Ti or Al, more preferably selected from Si or Ti, such as Si;

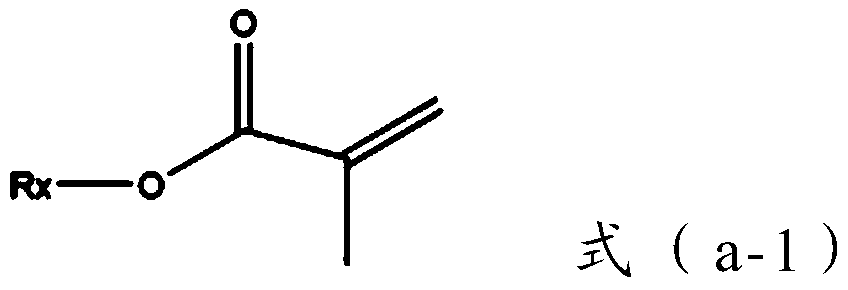

[0047] (2) R 1 from C 2 ~C 8 Alkenyl group, styryl group or group represented by formula (d-1), preferably selected from C 2 ~C 4 Alkenyl, styryl or groups represented by formula (d-1), more preferably selected from acryloyloxy, methacryloyloxy or vin...

Embodiment 1

[0149] Dissolve 10g of N-isopropylacrylamide, 0.5g of N,N-methylenebisacrylamide, and 2mg of potassium persulfate in 20ml of water, add 1g of trimethoxyvinylsilane into 30ml of toluene, and mix the above two solutions , then add 0.5g of sodium lauryl sulfate, stir and react at 90°C for 1 hour, cool to room temperature, centrifuge, collect the solid precipitate and wash with 50ml of water and ethanol three times respectively, and the white particles obtained are the dual-partition hybrid particles base.

[0150] Disperse 1 g of the above-prepared dual-partition hybrid particle substrate in 800 mL of water, add 20 mL of 0.1 mol / L palladium chloride hydrochloric acid solution, stir for 30 minutes, add 10 mL of 0.2 mol / L potassium borohydride dropwise, and ultrasonicate for 1 hour; centrifuge, After washing, a catalyst supported by bipartitioned hybrid particles is obtained.

Embodiment 2

[0152] Dissolve 1.6g of N-isopropylacrylamide, 0.2g of acrylic acid, 0.16g of N,N-methylenebisacrylamide and 20mg of ammonium persulfate in 40ml of water, then add 18mg of acryloyloxypropyltrimethyl Add oxysilane to 30ml toluene, mix the above two solutions, then add 0.5g sodium dodecyl sulfate, react at 70°C for 1h, cool to room temperature, add 1g tetraethyl orthosilicate, react for 48 hours, then centrifuge , the solid precipitate was collected and washed three times with 50 ml of water and ethanol respectively to obtain white particles which were the base of the dual-partition hybrid particles.

[0153] Dissolve the above-mentioned dual-partition hybrid particle substrate in 1L of water, then add 10ml of 0.2mol / L palladium chloride solution and 1mL of 1mmol / L chloroauric acid solution, ultrasonicate for 30min, and then add 4mL of 1wt.% sodium borohydride solution , and stirred for 2 hours, filtered and washed to obtain a catalyst supported by bipartitioned hybrid particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com