Reinforcing device for high-span portion of combined framework

A reinforcement device and high-span technology, applied in building construction, building maintenance, industrial buildings, etc., can solve problems such as hidden dangers in the operation of substation structures, and achieve the effects of enhancing overall rigidity, convenient and flexible use, and eliminating displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

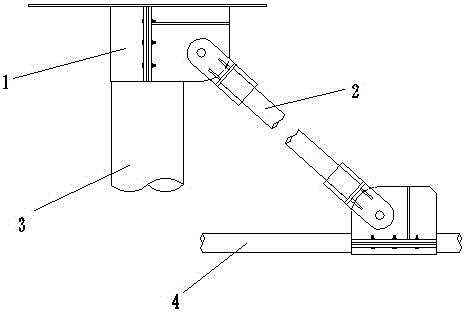

[0026] The combined frame includes a low-span part and a high-span part, the high-span part is arranged above the low-span part, the high-span part is provided with a high-span column, and the low-span part is provided with a low-span beam. The high-span part of the combined frame of this embodiment The reinforcement device is set on the high-span columns and low-span beams connected to each other in the joint frame. The structure is as follows: figure 1 As shown, it includes two hoops 1 and a connecting rod 2 between the two hoops 1, the two ends of the connecting rod 2 are respectively hinged with the two hoops 1, and the two hoops 1 are detachably fixed on the high On the span column 3 and the low span beam 4.

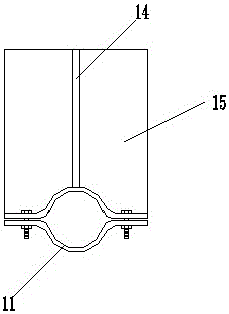

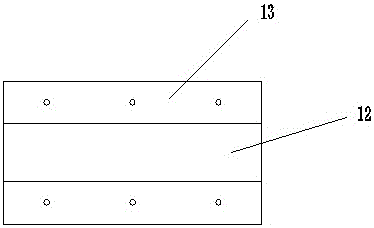

[0027] Such as figure 2 , 3 As shown in and 4, the hoop 1 includes two hoop bodies 11 that are symmetrical to each other. The hoop body 11 includes an arc cylindrical hoop portion 12 and fixing portions 13 located at both ends of the hoop portion. The fixing port...

Embodiment 2

[0035] The structure of the reinforcement device in this embodiment is basically the same as that of Embodiment 1, the difference is that the middle part of the connecting rod 2 in this embodiment is a high-strength spring, which allows the connecting rod to have a certain length adjustment range during use, and can adjust the length of the connecting rod. The horizontal force on the high-span part of the joint frame plays a certain buffering role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com