Efficient dissolved oxygen sewage aeration tank

A technology of sewage aeration and dissolved oxygen, applied in water aeration, water/sludge/sewage treatment, aerobic process treatment, etc. The effect of bubble formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

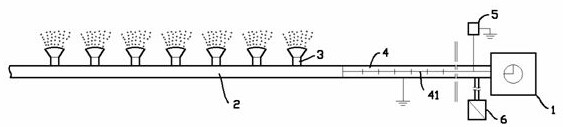

[0015] exist figure 1 In the first example shown, the high-efficiency dissolved oxygen sewage aeration tank includes a tank body (not shown) and an aeration system; the aeration system includes an air supply source 1, an air supply pipeline 2, and evenly distributed in the tank The microporous aeration head 3 in the body; the airflow output by the air supply source 1 is transported to each microporous aeration head 3 through the air supply pipeline 2, and forms air upward through the micropores on the top of the microporous aeration head 3. Fine bubbles; an electrostatic tube 4 insulated and connected to the gas supply pipeline 2 is also connected in series between the gas supply pipeline 2 and the gas supply source 1, and a corona wire 41 extending along the axis is arranged inside the static tube 4, The corona wire 41 is electrically connected to the first electrode of a high-voltage power supply 5; the end of the electrostatic tube 4 close to the gas supply source 1 is also...

Embodiment 2

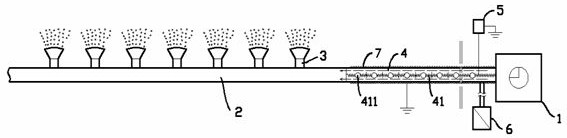

[0019] for figure 2 The second embodiment shown is different from the first embodiment in that an excitation solenoid 7 is sheathed on the outside of the electrostatic tube 4, so that an axial magnetic field is generated in the electrostatic tube 4; thus, the electrostatic tube 4 When the charged dust inside moves radially outward, it will be deflected around the axis by the Lorentz force, thereby significantly inhibiting the charged dust from flying to the tube wall of the electrostatic tube 4; the electrostatic tube 4, the gas supply pipeline 2 and The inner wall of the microporous aeration head 3 is also provided with a layer of antistatic film to prevent the charged dust from losing charge after hitting the inner wall of each component.

[0020] In addition, the air supply source 1 adopts an air pump with automatic power adjustment, and the air pump continuously fluctuates the air supply rate according to the setting; and the corona wire 41 is composed of a spring wire, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com