Cationic adsorbent prepared from grain stillage, preparation method for cationic adsorbent and application of cationic adsorbent

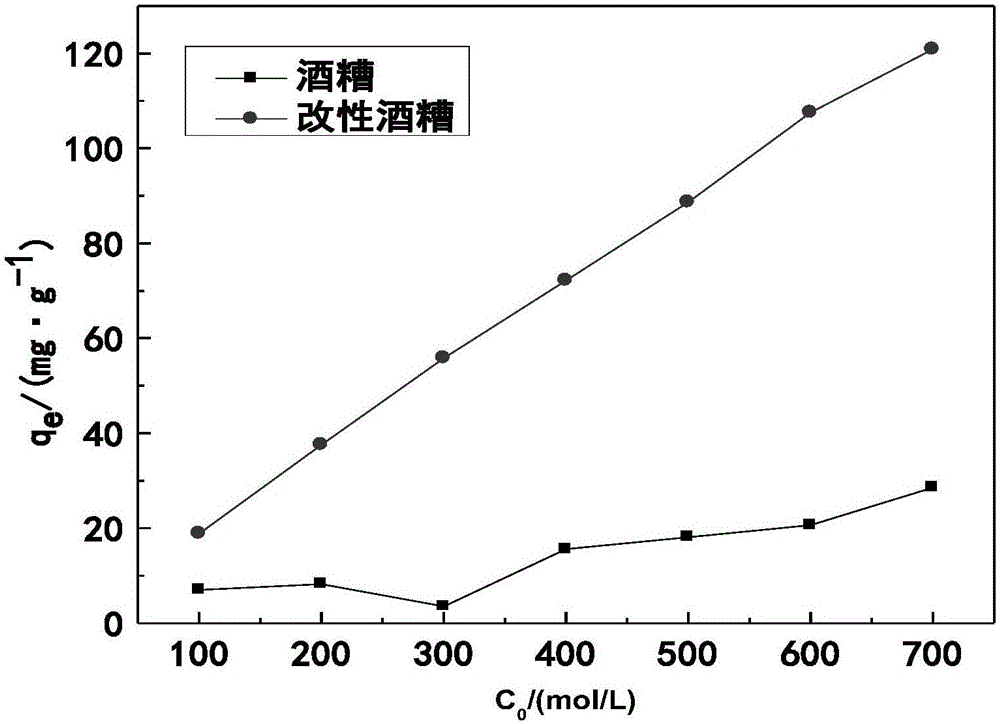

A technology of cation adsorption and distiller's grains, applied in the field of brewing waste resource utilization and environmental protection, can solve problems such as environmental pollution and waste of resources, and achieve the effects of low reaction energy consumption, increased adsorption rate, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for a cationic adsorbent prepared from distiller's grains, comprising the following steps:

[0030] 1) In terms of parts by mass, add 5 parts of potassium hydroxide to 50 parts of deionized water to obtain the first lye, cool to room temperature for subsequent use; add 1 part of sodium hydroxide to 50 parts of In deionized water, the second lye was obtained, cooled to room temperature for subsequent use;

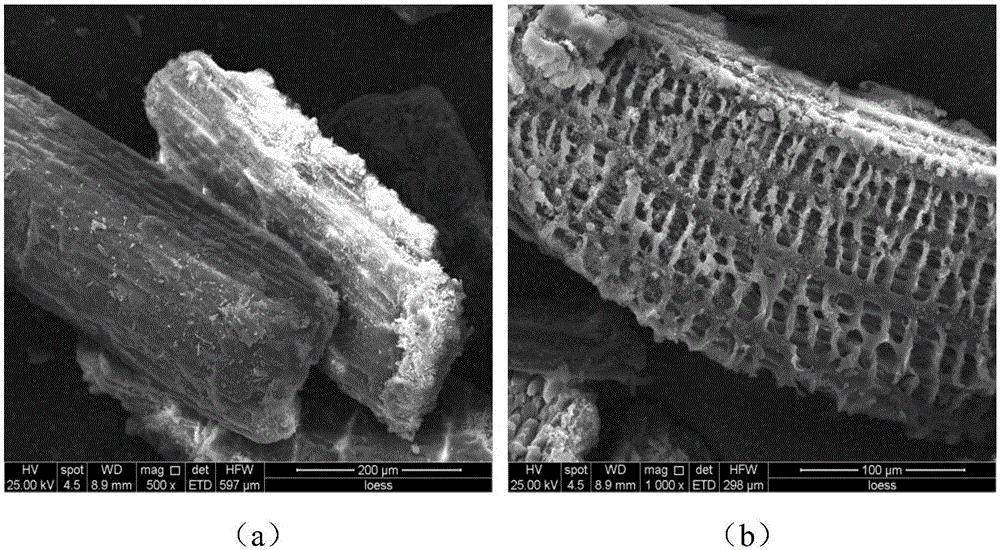

[0031] 2) In terms of parts by mass, add 1 part of 20-mesh distiller's grains to 1 part of the first lye, stir at 20°C and 60r / min for 0.5h, wash with deionized water twice until neutral, drying at 30°C to obtain pretreated distiller's grains;

[0032] 3) In terms of parts by mass, add 1 part of pretreated distiller's grains to 1 part of the second lye, stir at 20°C and 60 r / min for 0.1 h, add 0.2 parts of ethylenediamine and 0.3 parts of trimethyl The amine was reacted for 0.5h, washed twice with absolute ethanol, then washed with deionized water until neu...

Embodiment 2

[0034] A method for a cationic adsorbent prepared from distiller's grains, comprising the following steps:

[0035] 1) In terms of parts by mass, add 10 parts of sodium carbonate to 100 parts of deionized water to obtain the first lye, cool to room temperature for subsequent use; add 5 parts of potassium hydroxide to 250 parts of deionized water by mass ratio In deionized water, obtain the second lye, cool to room temperature for subsequent use;

[0036] 2) In terms of parts by mass, add 6 parts of 80-mesh yellow rice distiller's grains to 7 parts of the first lye, stir at 30°C and 80r / min for 1.5h, wash with deionized water 3 times until neutral, and drying at 45°C to obtain pretreated distiller's grains;

[0037] 3) In terms of parts by mass, add 3 parts of pretreated distiller's grains to 4 parts of the second lye, stir at 30°C and 80r / min for 3 hours, add 1 part of dimethylamine and 4 parts of diethylenetri The amine was reacted for 5 hours, washed three times with absol...

Embodiment 3

[0039] A method for a cationic adsorbent prepared from distiller's grains, comprising the following steps:

[0040] 1) In terms of parts by mass, add 20 parts of sodium hydroxide to 200 parts of deionized water to obtain the first lye, cool to room temperature for subsequent use; add 15 parts of sodium bicarbonate to 300 parts of In deionized water, the second lye was obtained, cooled to room temperature for subsequent use;

[0041] 2) In terms of parts by mass, add 12 parts of 150-mesh distiller's grains to 14 parts of the first lye, stir at 40°C and 140r / min for 3 hours, wash with deionized water 5 times until neutral, and drying to obtain pretreated distiller's grains;

[0042] 3) In terms of parts by mass, add 12 parts of pretreated distiller's grains to 14 parts of the second lye, stir at 40°C and 140r / min for 3.5h, add 10 parts of tetradecyl trimethyl chloride React with ammonium for 3 hours, wash with absolute ethanol for 5 times, and then wash with deionized water un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com