Multiwalled carbon nanotube hybrid ultrafiltration membrane with anti-pollution, self-cleaning and antibacterial properties

A technology of multi-wall carbon nanotubes and ultrafiltration membranes, applied in the field of membrane separation, can solve the problems of not being able to directly obtain dry powder preparations, and achieve good application prospects, pollution-free operation, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

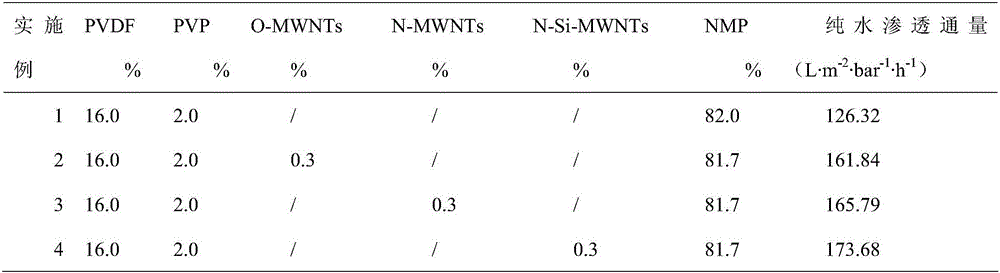

Embodiment 1~4

[0032] Disperse 5 grams of MWNTs in a 0.5 mol / L dilute hydrochloric acid solution, sonicate for 10-30 minutes, let stand for 12 hours, vacuum filter, wash until neutral, and dry to obtain purified MWNTs. Put 1 gram of purified MWNTs into an activation kettle, add 10 ml of concentrated nitric acid, heat at 160°C for 6 hours, vacuum filter, wash until neutral, and dry to obtain O-MWNTs. Mix 0.05 moles of 5,5-dimethylhydantoin, 0.05 moles of NaOH, and 40 ml of water and stir at room temperature for 5 to 10 minutes, then add 0.05 moles of epichlorohydrin and stir at room temperature for 10 hours, remove the solvent water by rotary evaporation, and add acetone for purification. The by-product NaCl was removed by filtration, and the acetone was removed by rotary evaporation to obtain the crude product 3-epoxypropyl-5,5-dimethylhydantoin. 10% aqueous solution of 3-epoxypropyl-5,5-dimethylhydantoin, 1% NaOH, 10% O-MWNTs, stirring at 60°C for 30 minutes, curing at 60°C for 1 hour, curi...

Embodiment 5~8

[0038] The PVDF composite ultrafiltration membranes of Examples 1 to 4 are used as membrane modules in a cross-flow filtration device. After the pure water is pre-pressurized, the bovine serum albumin (BSA) (Mw=67000) solution is filtered until the flux is stable and a certain amount of filtrate is collected. Wash with pure water at low pressure for 30 minutes, measure the pure water flux of the membrane again, and study the interception performance and self-cleaning performance. The calculated flux recovery rate and protein retention rate are shown in Table 2.

[0039] Table 2: Flux recovery rate of PVDF composite ultrafiltration membrane

[0040]

Embodiment 1

[0042] The PVDF composite ultrafiltration membranes of Examples 1-4 were used as antibacterial materials, and their antibacterial effects on Escherichia coli and Staphylococcus aureus were investigated by plate coating method. The calculated antibacterial rate is shown in Table 3. Embodiment 1 and embodiment 4 are to Escherichia coli and Staphylococcus aureus antibacterial effect figure see figure 2 .

[0043] Table 3: Antibacterial rate of PVDF composite ultrafiltration membrane against Escherichia coli and Staphylococcus aureus

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com