Negative ion biomass aldehyde removing agent

A technology of biomass and aldehyde remover, which is applied in the field of air purification, can solve the problems of difficult removal, easy damage and re-release, ammonia pollution, etc., and achieve the effect of increasing the content of negative ions, benefiting human health, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

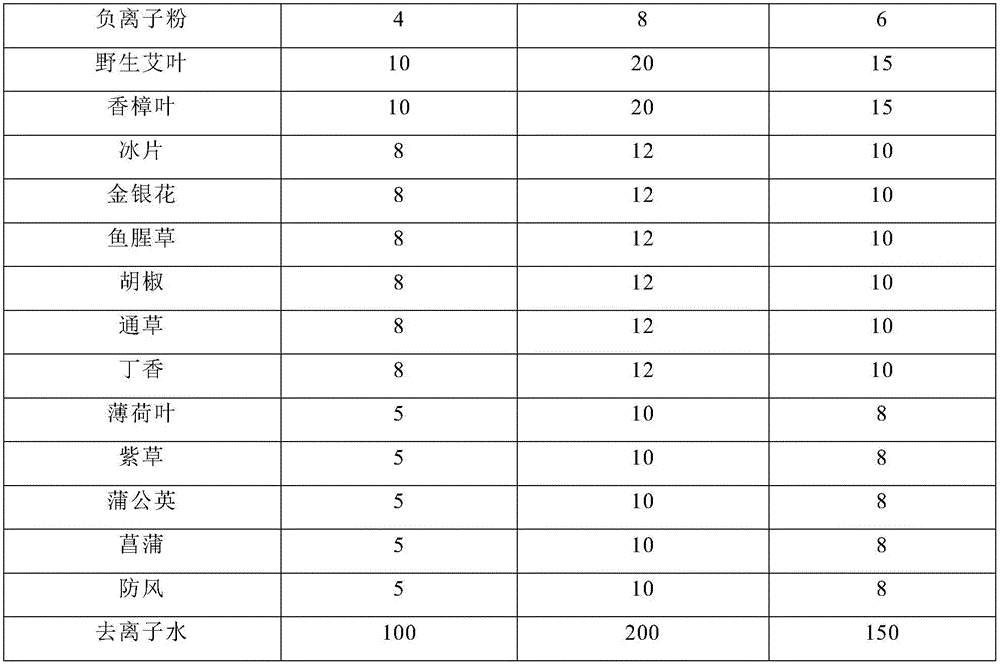

Embodiment 1

[0028] A negative ion biomass aldehyde remover, the biomass raw material is bagasse.

[0029] The preparation method of described negative ion biomass aldehyde removal agent comprises the following steps:

[0030] (1) After pulverizing the biomass raw material and adding deionized water, adjust the pH value to neutral, add polysaccharide hydrolase to hydrolyze, after the hydrolysis is completed, filter the supernatant, add sodium citrate and let it stand for 12 hours, then pass through a 600-mesh sieve to filter liquid, spare;

[0031] (2) Wash the wild mugwort leaves, camphor leaves, borneol, honeysuckle, Houttuynia cordata, pepper, Tongcao, cloves, mint leaves, comfrey, dandelion, calamus, windproof, dry and mix them into fine powder powder spare;

[0032] (3) Add the fine powder and negative ion powder of step (2) into the extraction tank, add 8 times the weight of solvent, soak at 50°C for 4h, then heat and reflux at 60°C for 1h, and filter to obtain the filter residue a...

Embodiment 2

[0042] A negative ion biomass aldehyde remover, the biomass raw material is bagasse.

[0043] The preparation method of described negative ion biomass aldehyde removal agent comprises the following steps:

[0044] (1) After pulverizing the biomass raw material and adding deionized water, adjust the pH value to neutral, add polysaccharide hydrolase for hydrolysis, after the hydrolysis is completed, filter the supernatant, add sodium citrate and let it stand for 24 hours, then pass through a 1000-mesh sieve to filter liquid, spare;

[0045] (2) Wash the wild mugwort leaves, camphor leaves, borneol, honeysuckle, Houttuynia cordata, pepper, Tongcao, cloves, mint leaves, comfrey, dandelion, calamus, windproof, dry and mix them into fine powder powder spare;

[0046] (3) Add the fine powder and negative ion powder of step (2) into the extraction tank, and add 16 times the weight of solvent, soak at 60°C for 8h, then heat and reflux at 80°C for 2h, and filter to obtain the filter r...

Embodiment 3

[0056] A negative ion biomass aldehyde remover, the biomass raw material is bagasse.

[0057] The preparation method of described negative ion biomass aldehyde removal agent comprises the following steps:

[0058] (1) After pulverizing the biomass raw material and adding deionized water, adjust the pH value to neutral, add polysaccharide hydrolase for hydrolysis, after the hydrolysis is completed, filter the supernatant and add sodium citrate to stand for 16 hours, then pass through an 800-mesh sieve to filter liquid, spare;

[0059] (2) Wash the wild mugwort leaves, camphor leaves, borneol, honeysuckle, Houttuynia cordata, pepper, Tongcao, cloves, mint leaves, comfrey, dandelion, calamus, windproof, dry and mix them into fine powder powder spare;

[0060] (3) Add the fine powder and negative ion powder of step (2) into the extraction tank, add 12 times the weight of solvent, soak at 55°C for 6h, then heat and reflux at 70°C for 1-2h, and filter to obtain the filter residue a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com