Easily settable stretch fabric comprising low-melt fibers

A low-melting fiber and fabric technology, applied in the direction of fabric, braid, fiber processing, etc., can solve the problem of not being able to change and control the stretch level of the fabric, and achieve good spandex slip, anti-bending and anti-spinning properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

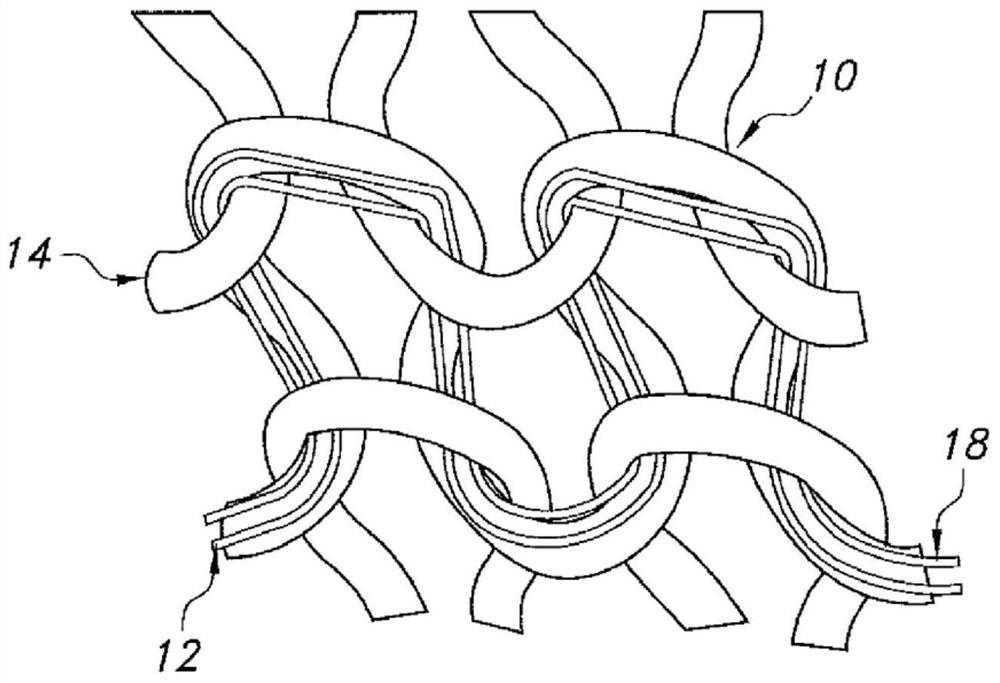

[0148] Example 1: Low Melt Fiber: Bicomponent Fiber

[0149] Low melting point fiber LOMELA manufactured by Huvis TM Used to make composite yarns and fabrics. LOMELA(TM) is a low melting bicomponent filament with a core and sheath structure. The sheath is a low melt polymer and the core is conventional polyester. During the heat activation process, the fibers can readily develop the bonding function that requires a stable form. A yarn with 36 filaments is 75 denier. The melting temperature of the sheath component part was 165°C. When the heating temperature is lower than 150°C, the fibers look and behave as regular polyester fibers. When the temperature reaches 150°C or higher, the low melting skin begins to soften and melt. When the temperature reaches 165°C, the sheath part is completely melted and fused with the core fiber. The individual 36 filaments are fused and bonded together to form a single strand. It also connects and bonds with adjacent rigid fibers and ela...

example 2

[0150] Example 2: Low melting point fiber: single component fiber

[0151] Monocomponent fibers comprising "polyolefin" polymers are used as low-melt fibers. The fibers were spun into one filament of 40D. The fiber starts to melt at 135.65°C and reaches the melting peak at 146.26°C. The thermal activation process may be performed at a temperature in the range of about 120°C for a period of 5 seconds to several minutes. After melting, it bonds with adjacent rigid and elastic fibers to form a cross-linked structure within the fabric.

example 3

[0152] Example 3: Single Core Yarn

[0153] 40D The fiber core is surrounded by 75D / 36f low-melt bicomponent yarn. Elongated at 3.0X during coring fiber. Yarns have high recovery and surface gloss aesthetics due to the low melting point bicomponent fibers. This core yarn can be used in hosiery, pantyhose, socks as well as knitting and weaving applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com