winding spindle

A spindle and winding machine technology, applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problems of increasing the strength of the drive shaft, achieve strength improvement, avoid high notch stress, and increase design strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

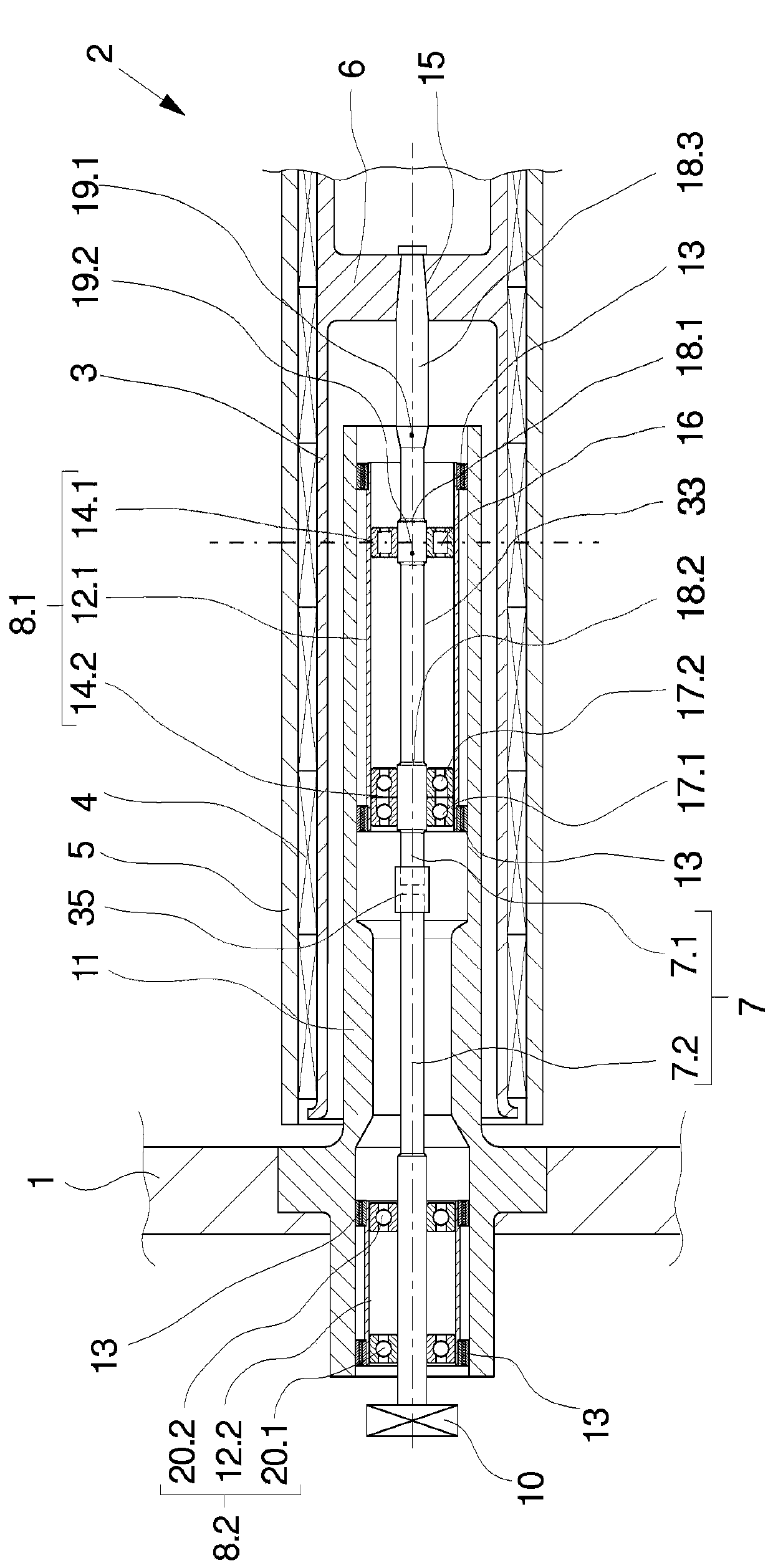

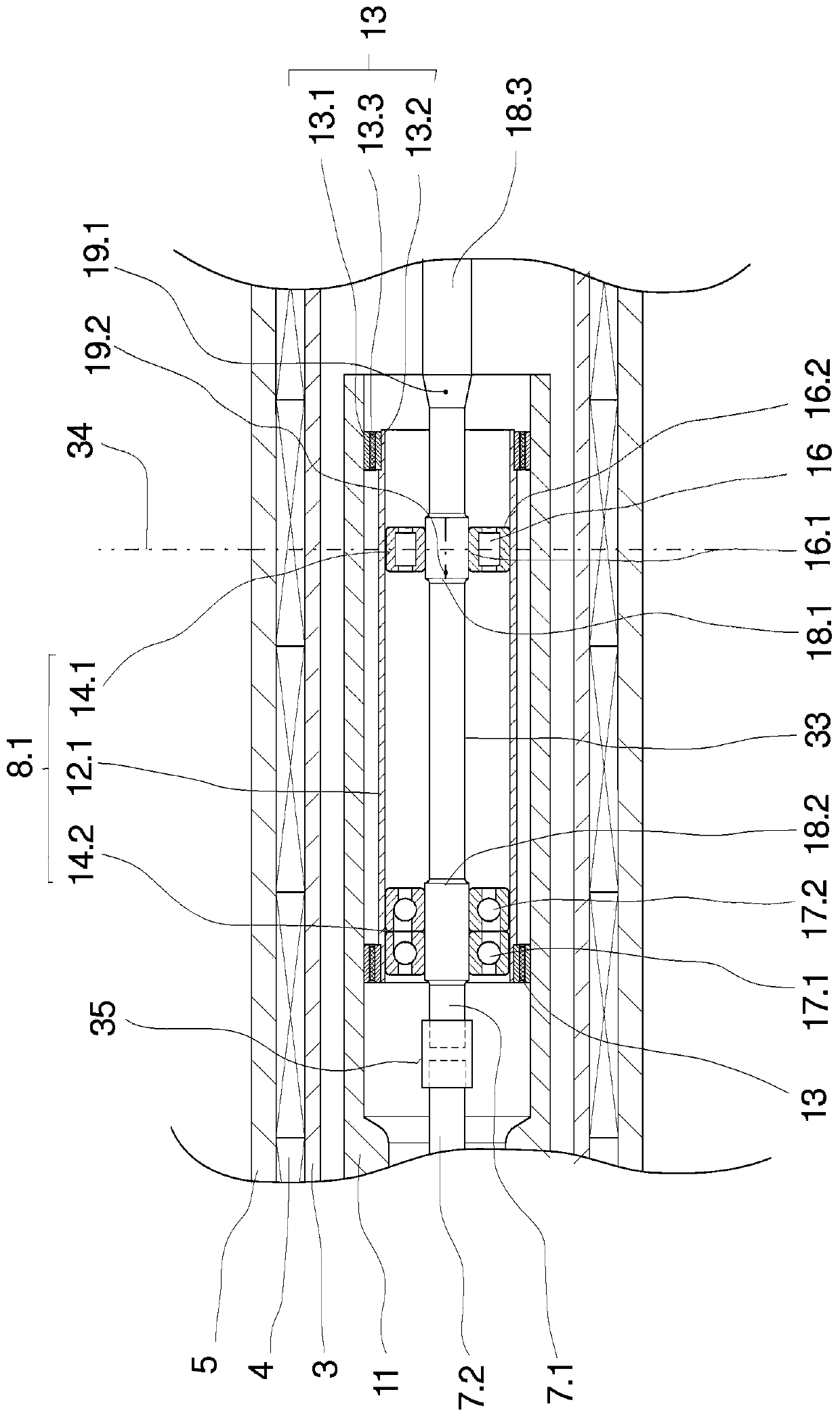

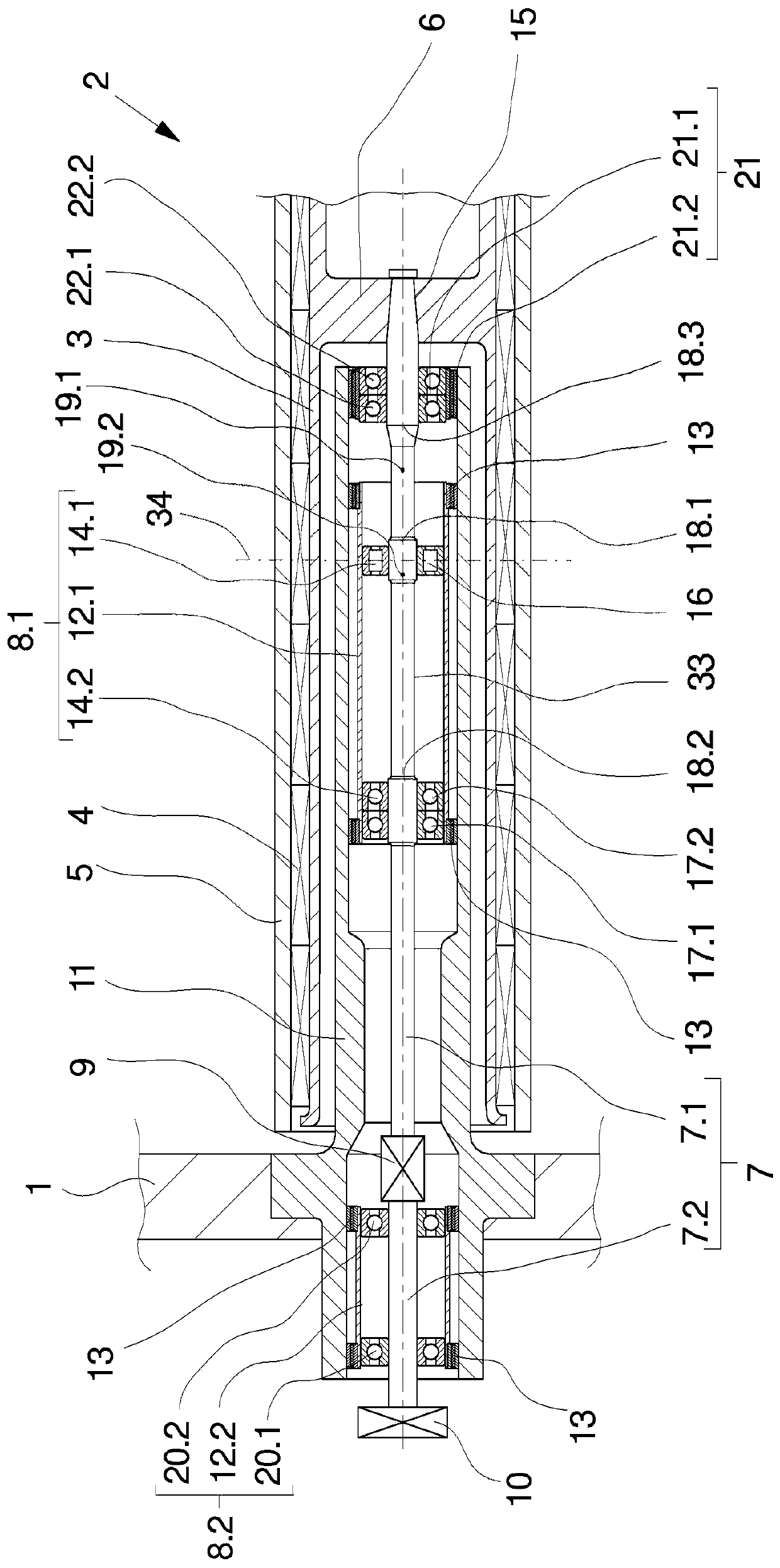

[0031] in figure 1 A cross-sectional view of the first exemplary embodiment of the winding spindle is illustrated in a partial view. The winding spindle 2 is held on the spindle support 1 by a hollow support 11. The winding spindle 2 on the spindle support 1 has a large number of protruding chucks 3, and the chucks 3 are configured to be hollow cylindrical at both ends. The free end of chuck 3 is figure 1 It is not shown in, this is because the free end does not include any components related to the present invention. The free end of the chuck 3 is usually closed by a cover.

[0032] The relatively open end of the chuck 3 facing the spindle support 2 is used to receive the drive shaft 7, and the drive shaft 7 is connected to the hub 6 of the chuck 3 through a shaft-hub connection 15.

[0033] Due to production technology, the drive shaft 7 is divided into two shaft parts and formed by a front bearing shaft 7.1 and a rear bearing shaft 7.2. The two bearing shafts 7.1 and 7.2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com