An integrated embedded part for hoisting and oblique bracing and its application method

A hoisting and diagonal bracing technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of no inspection standards for embedded hanging parts, poor appearance quality and durability, hidden safety hazards of embedded hanging parts, etc., to improve the appearance Quality, clear structural stress, and improved design strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

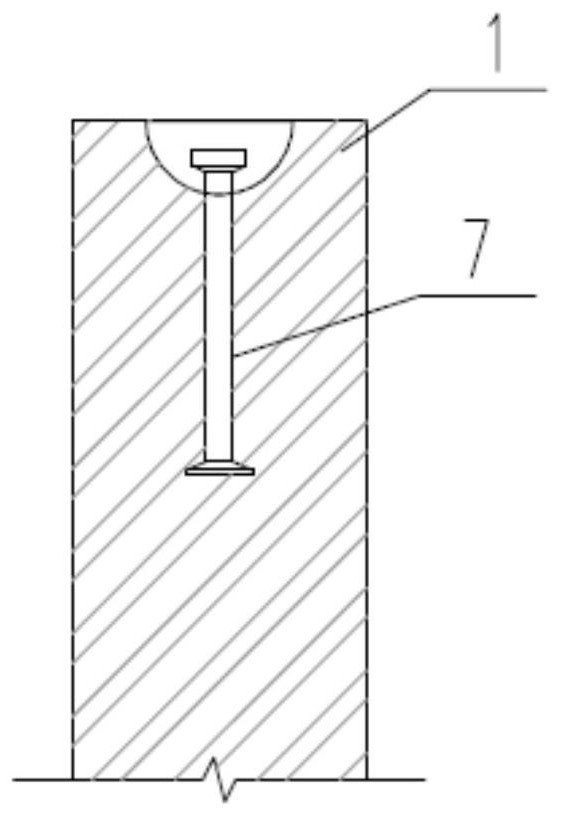

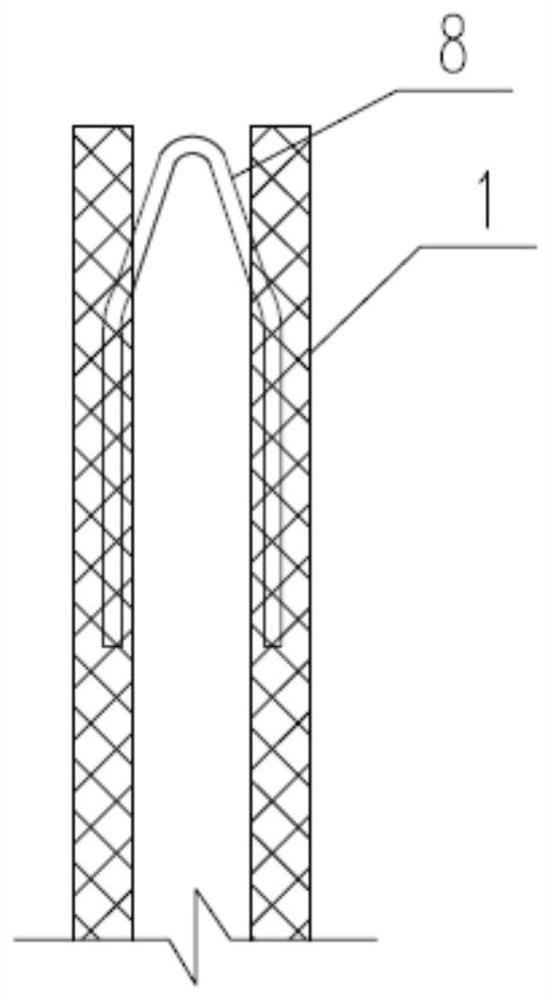

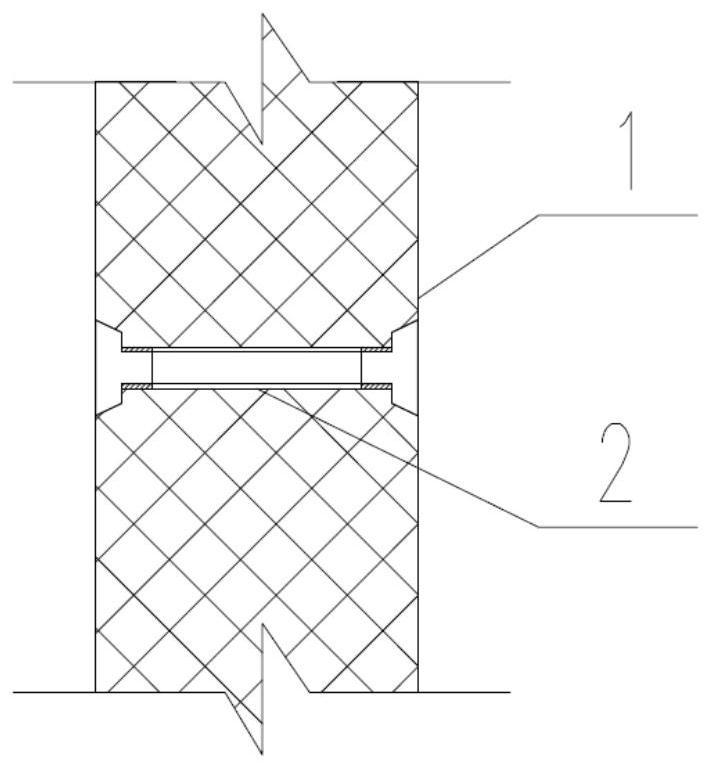

[0037] see Figure 1-Figure 10 , the present invention relates to a hoisting brace integrated embedded part, comprising a prefabricated wall panel 1, a hoisted diagonal brace integrated embedded part 2, a magnetic cover 3, and a hoisting steel rod 4; the prefabricated wall panel 1 is provided with a hoisting inclined Bracing integrated embedded part 2 is fixed on the formwork platform for the production of prefabricated wallboard 1 through the magnetic cover 3. The magnetic cover is removed during hoisting, and the hoisting steel rod 4 is passed through the hoisting ramp. To support the integrated embedded part, the hoisting sling 5 is connected to the hoisting steel rod 4 for hoisting, and the brace bolt 6 is screwed into the integrated embedded part 2 for hoisting the brace on the construction site to achieve the function of the brace of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com