Mesoporous silica/carbon-sulfur compound for lithium sulphur battery cathode and its preparation method

A technology of mesoporous silicon oxide and sulfur-carbon composites, which is applied in the field of nanocomposite materials and its preparation, can solve the problems of unfavorable fast charging and discharging, and achieve the effects of reducing shuttle effect, low production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

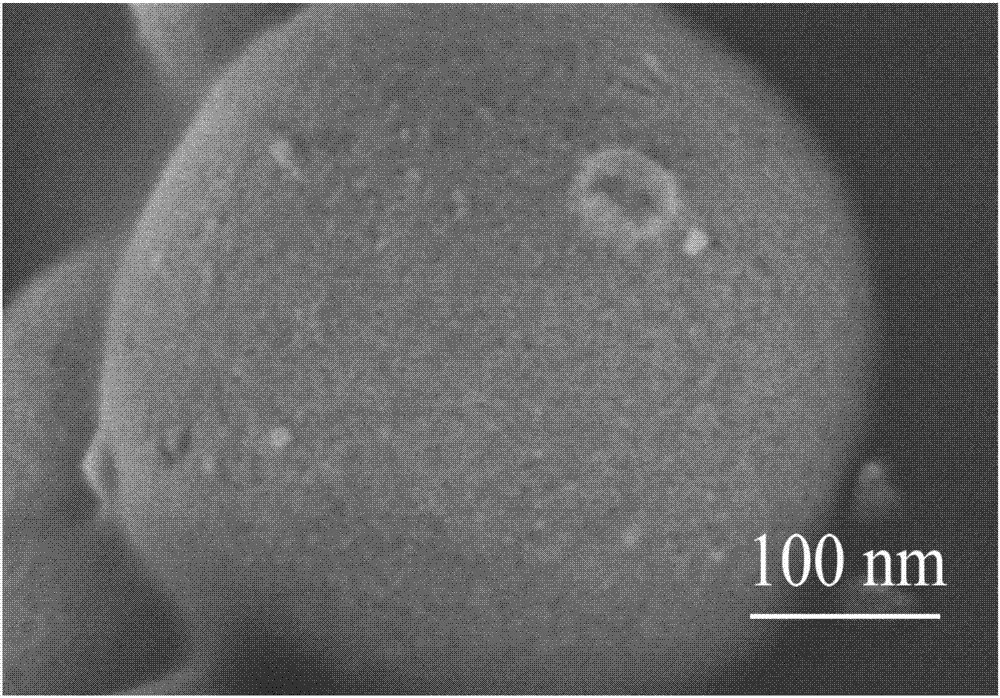

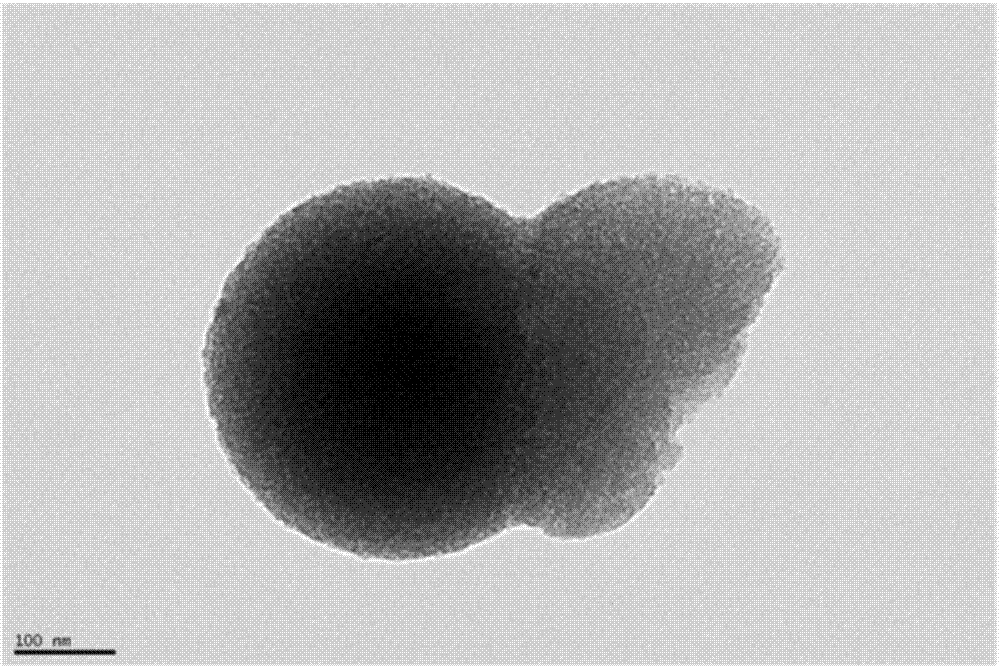

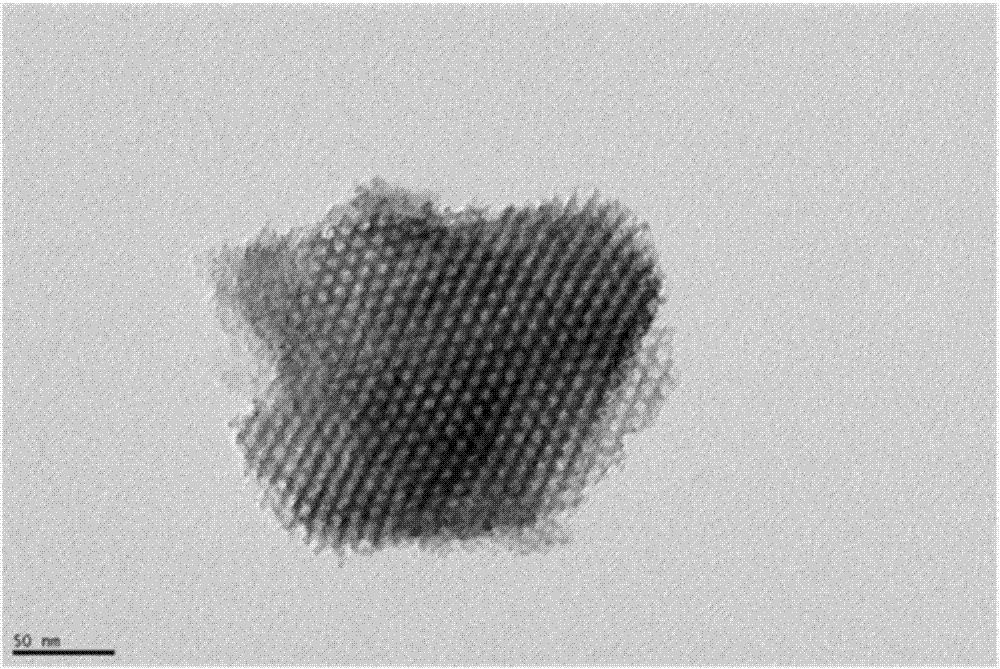

[0048] Specific Embodiment 1: The mesoporous silicon oxide / sulfur-carbon composite used for the positive electrode of the lithium-sulfur battery in this embodiment is composed of mesoporous silicon oxide, elemental sulfur and carbon materials, and the elemental sulfur occupies the mesoporous oxidation of the positive electrode of the lithium-sulfur battery. 10% to 80% of the total mass of the silicon / sulfur-carbon composite.

specific Embodiment approach 2

[0049] Specific embodiment two: the preparation method of the mesoporous silicon oxide / sulfur-carbon composite used for the positive electrode of lithium-sulfur battery described in specific embodiment one:

[0050] 1. Preparation of silica-sulfur complex:

[0051] Mix sublimated sulfur and mesoporous silicon oxide according to the mass ratio of (10~1):1, under the protection of nitrogen or argon atmosphere, keep warm for 6h~20h at a temperature of 158°C~160°C, and then raise the temperature to 250°C ℃~300℃ and continue to keep warm for 0.5h~3h to obtain silicon oxide sulfur compound;

[0052] 2. Disperse the silica-sulfur complex obtained in step 1 in water, stir and disperse it with magnetic force, add it into the aqueous solution of carbon material with a concentration of 1 mg / mL, continue stirring for 12 to 48 hours, precipitate, centrifuge, wash, and dry, that is Obtained mesoporous silicon oxide / sulfur-carbon composites for lithium-sulfur battery cathodes.

specific Embodiment approach 3

[0053] Embodiment 3: This embodiment differs from Embodiment 2 in that the mass content of sulfur in the silica-sulfur composite obtained in step 1 is 10-80%. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com