Turbine-pressure separation energy storage type engine pressurization system

A technology for engines and storage batteries, applied to combustion engines, engine components, machines/engines, etc., can solve the problems of low thermal efficiency of engines and achieve the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

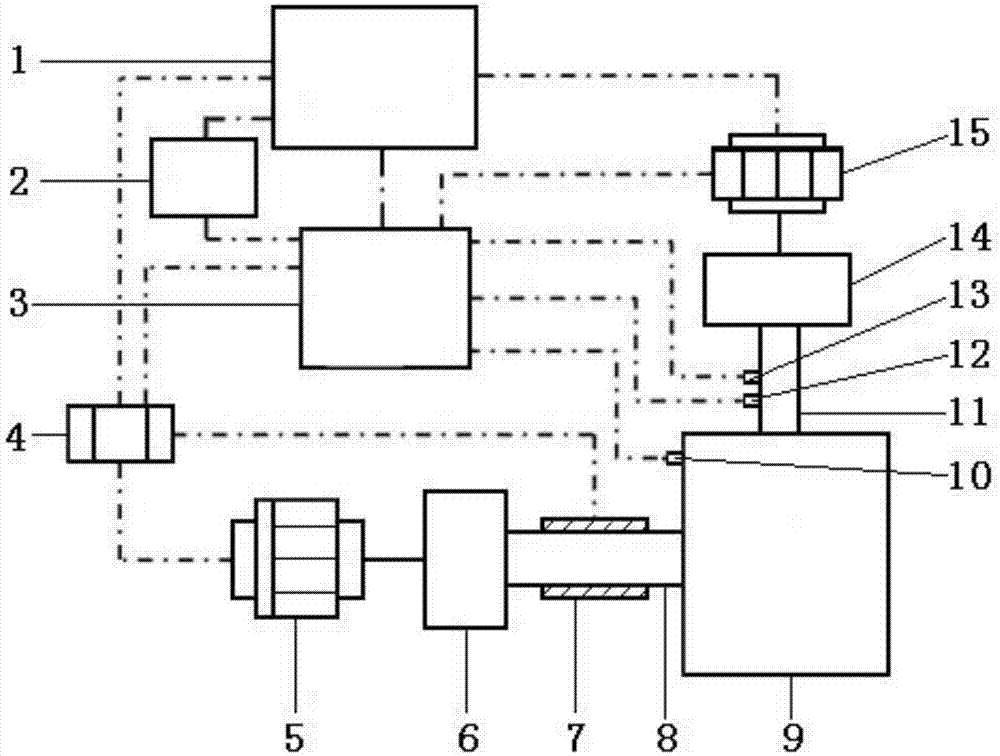

[0022] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0023] Such as figure 1 As shown, the present invention consists of a storage battery 1, a power detection module 2, a control module 3, a rectification filter circuit 4, a generator 5, a turbine 6, a thermoelectric conversion module group 7, an engine exhaust pipe 8, an engine 9, an engine speed sensor 10, Engine intake pipe 11, intake air temperature sensor 12, intake air pressure sensor 13, electrically driven compressor 14 and high power density DC motor 15, wherein the engine exhaust pipe 8 outlet of the thermoelectric conversion module group 7 is attached to the outer wall and the turbine 6 input connections.

[0024] The engine exhaust pipe 8 inlet is connected with the outlet of the exhaust port of the engine 9, the outlet of the engine intake pipe 11 is connected with the inlet of the engine 9, and the inlet of the engine inlet pipe 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com