T-shaped blade root of turbine blade and matched flangeway thereof

A technology for steam turbine blades and flange grooves, which is applied to blade support components, mechanical equipment, engine components, etc., and can solve problems such as high technological requirements for blade roots and flange grooves, affecting the safe operation of blades, and inability to process pin holes, etc. Achieve the effect of good manufacturability, large bearing capacity and compact axial structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with accompanying drawing:

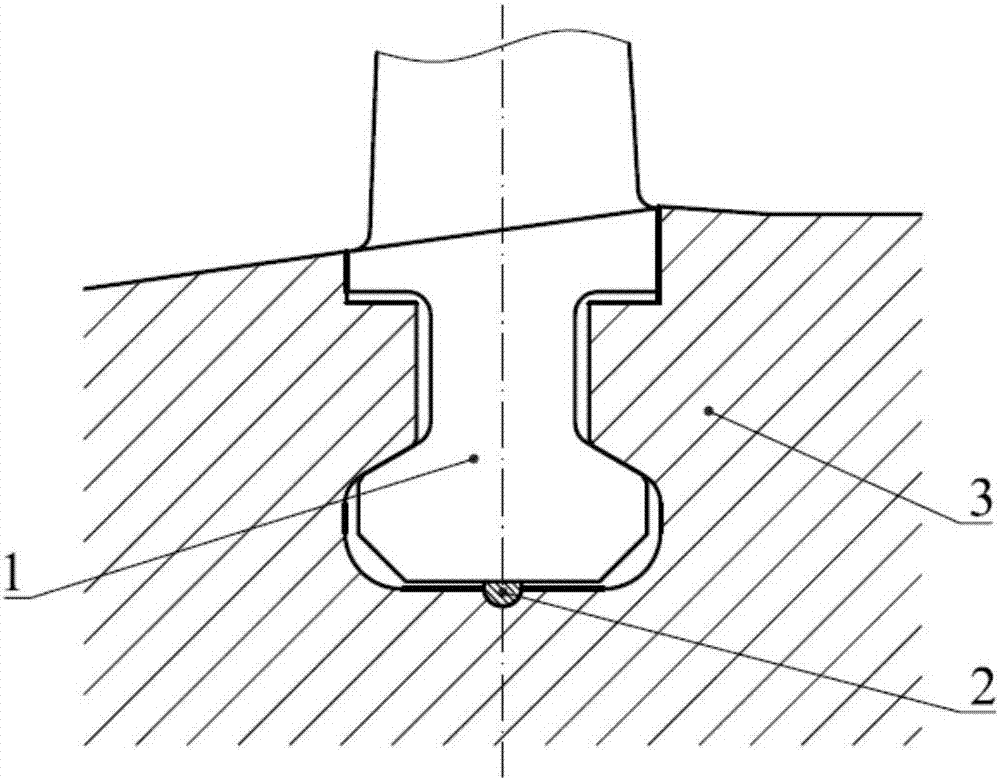

[0041] Such as figure 1 As shown, a T-shaped blade root of a steam turbine blade and its matching rim groove include a steam turbine blade inclined T-shaped blade root 1, a spacer strip 2, and a rim groove 3, the bottom of the inclined T-shaped blade root and the bottom surface of the rim groove Install spacers between them. The oblique T-shaped blade root of the steam turbine blade includes a T-shaped head, a neck, a connecting section between the blade root and the blade body.

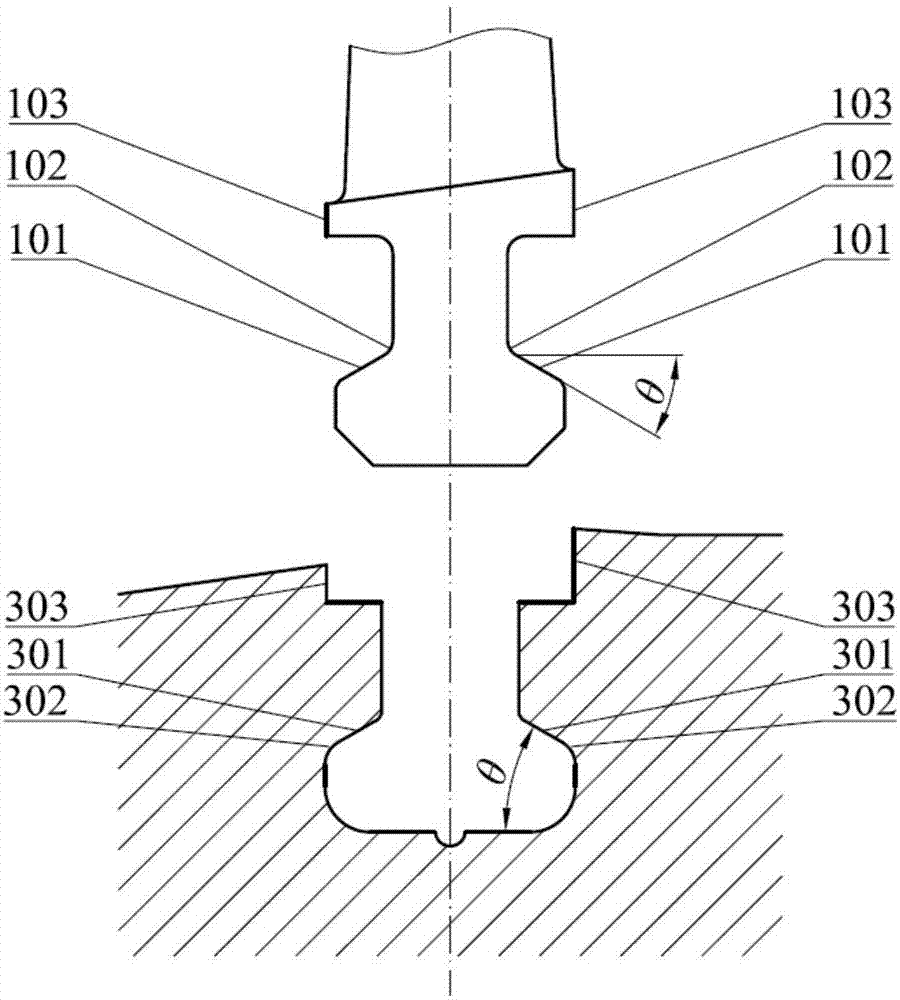

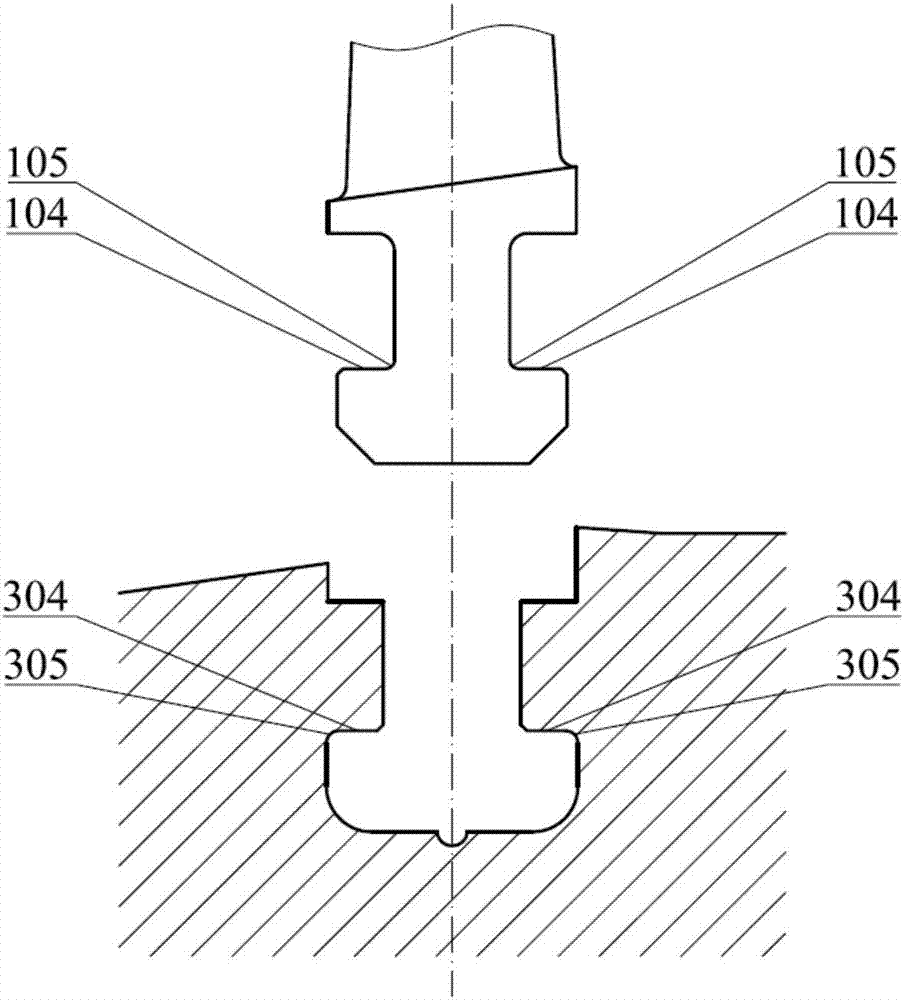

[0042] Such as figure 1 , figure 2 As shown, the oblique T-shaped blade root 1 has an oblique T-shaped head, so the oblique T-shaped head bearing surface 101 and the matching flange groove bearing surface 301 form an included angle θ with the axial direction of the steam turbine. After assembly, the oblique T-shaped blade root 1 is lifted up by the spacer strip 2 at the bottom, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com