Annular pressure monitoring and controlling device for deepwater oil-gas well

A technology of annular pressure and control devices, which is applied in the direction of measuring, flushing boreholes, boreholes/well components, etc., and can solve the problem of not being able to test the tightness and integrity of casings in deepwater oil and gas wells, and the control effect of annular pressure is not very ideal , annular pressure with pressure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

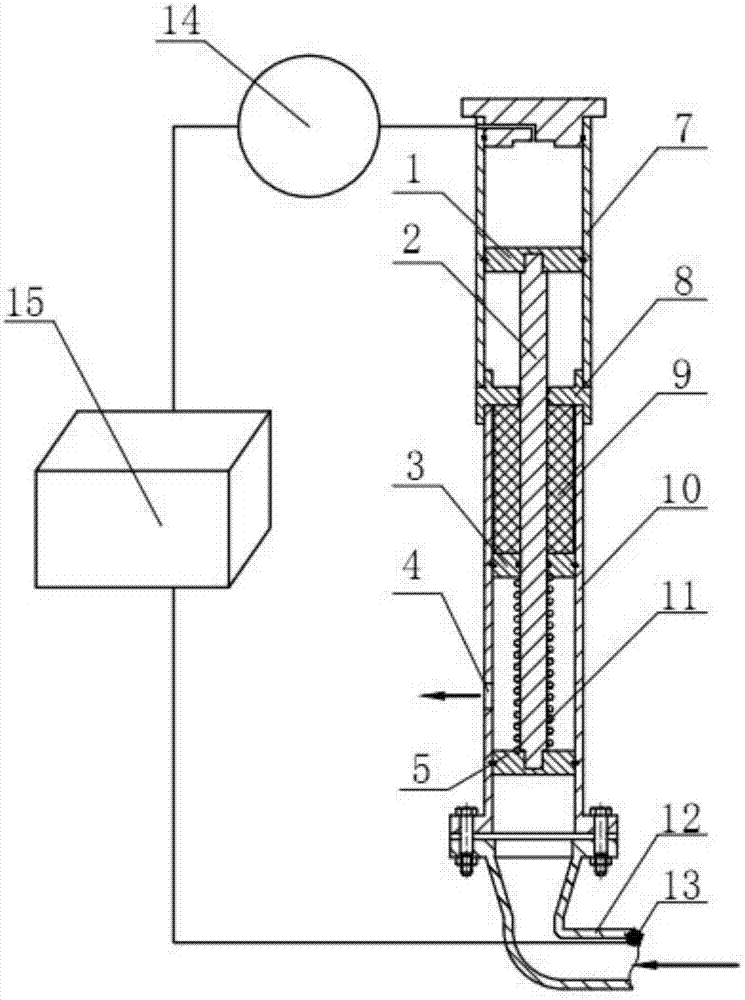

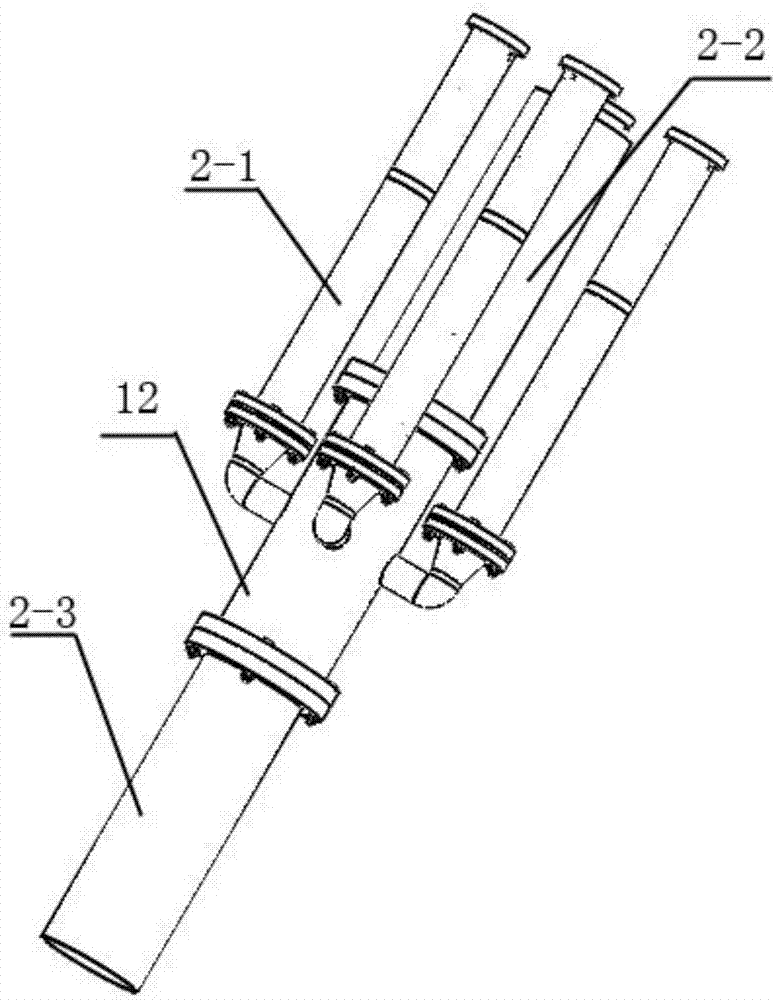

[0019] like figure 1 Shown: the annular pressure monitoring and control device at the wellhead of deep water oil and gas wells, including the upper hydraulic cylinder 7, the upper piston 1 in the upper hydraulic cylinder 7 is connected to the lower piston 5 in the lower hydraulic cylinder 10 through the piston rod 2; the upper hydraulic cylinder 7 Connect the lower hydraulic cylinder 10 through the connector 8; the side wall of the lower hydraulic cylinder 10 is provided with a pressure relief port 4; the lower hydraulic cylinder 10 is provided with a compression rubber cylinder 9, and the bottom of the compression rubber cylinder 9 is provided with an annular piston 3, which The piston 3 is connected to the lower piston 5 through the spring 11, and the system composed of the spring 5 and the compressible rubber cylinder 9 is used as a pressure buffer structure, which ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com