A kind of weather-resistant fabric coating and preparation method thereof

A fabric and coating technology, applied in the direction of coating, can solve the problem of low comprehensive performance, and achieve the effects of simple process, low preparation cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

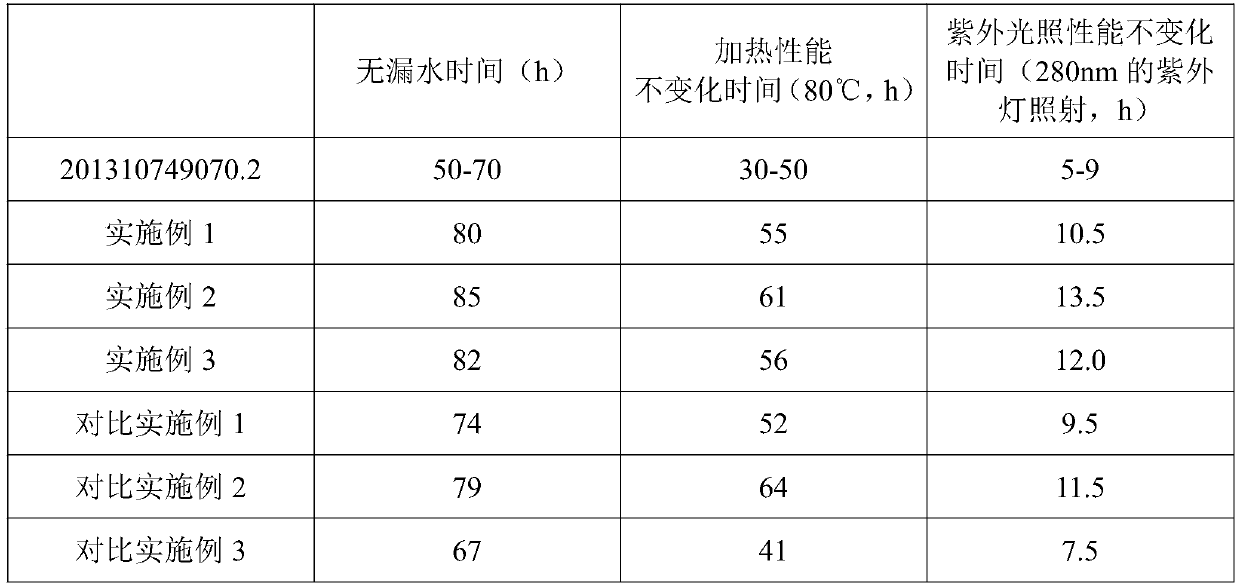

Examples

Embodiment 1

[0023] Composition of raw materials: ethanol 25%, 2-hydroxy-4-n-octyloxybenzophenone 2%, ethyl acetate 0.1%, polyamide resin 2%, oxide composite powder 30%, acrylic acid 0.1%, the rest is Polyurethane. Oxide composite powder is SiO 2 -SnO 2 -NiO 2 Composite powder, where SiO 2 , SnO 2 , NiO 2 The weight ratio is 1:1:0.3. SiO 2 -SnO 2 -NiO 2 The particle size of the composite powder is 90-100nm.

[0024] SiO 2 -SnO 2 -NiO 2 Composite powder is prepared by the following steps:

[0025] Step S1, put nickel acetate tetrahydrate into acetic anhydride and stir (per 100g of nickel acetate tetrahydrate corresponds to 1000mL of acetic anhydride), heat reflux at 120°C for 15h; then separate the crystals, wash with acetic anhydride for 3 times and then drain , placed in a vacuum desiccator filled with solid sodium hydroxide and dried to obtain object No. 1 for use;

[0026] Step S2, NaCl, SnCl 2 2H 2 O and KCl are prepared according to the weight ratio of 10:8:13, put in...

Embodiment 2

[0033] Composition of raw materials: ethanol 32%, 2-hydroxy-4-n-octyloxybenzophenone 3%, ethyl acetate 0.3%, polyamide resin 5%, oxide composite powder 35%, acrylic acid 0.3%, the rest is Polyurethane. Oxide composite powder is SiO 2 -SnO 2 -NiO 2 Composite powder, where SiO 2 , SnO 2 , NiO 2 The weight ratio is 1:1:0.3. SiO 2 -SnO 2 -NiO 2 The particle size of the composite powder is 90-100nm.

[0034] SiO 2 -SnO 2 -NiO 2 Composite powder is prepared by the following steps:

[0035] Step S1, put nickel acetate tetrahydrate into acetic anhydride and stir (per 100g of nickel acetate tetrahydrate corresponds to 1000mL of acetic anhydride), heat reflux at 120°C for 15h; then separate the crystals, wash with acetic anhydride for 3 times and then drain , placed in a vacuum desiccator filled with solid sodium hydroxide and dried to obtain object No. 1 for use;

[0036] Step S2, NaCl, SnCl 2 2H2 O and KCl are prepared according to the weight ratio of 10:8:13, put into...

Embodiment 3

[0043] Composition of raw materials: ethanol 28%, 2-hydroxy-4-n-octyloxybenzophenone 2.5%, ethyl acetate 0.2%, polyamide resin 4%, oxide composite powder 32%, acrylic acid 0.2%, the rest is Polyurethane. Oxide composite powder is SiO 2 -SnO 2 -NiO 2 Composite powder, where SiO 2 , SnO 2 , NiO 2 The weight ratio is 1:1:03. SiO 2 -SnO 2 -NiO 2 The particle size of the composite powder is 90-100nm.

[0044] SiO 2 -SnO 2 -NiO 2 Composite powder is prepared by the following steps:

[0045] Step S1, put nickel acetate tetrahydrate into acetic anhydride and stir (per 100g of nickel acetate tetrahydrate corresponds to 1000mL of acetic anhydride), heat reflux at 120°C for 15h; then separate the crystals, wash with acetic anhydride for 3 times and then drain , placed in a vacuum desiccator filled with solid sodium hydroxide and dried to obtain object No. 1 for use;

[0046] Step S2, NaCl, SnCl 2 2H 2 O and KCl are prepared according to the weight ratio of 10:8:13, put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com