PET carrier tape production forming system based on high-precision and high-speed particle machine

A high-speed particle and high-precision technology, applied to belts, other household appliances, household appliances, etc., can solve the problems of low production efficiency, mechanical design and unacceptable efficiency, and achieve the effect of eliminating surface bumps and concaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

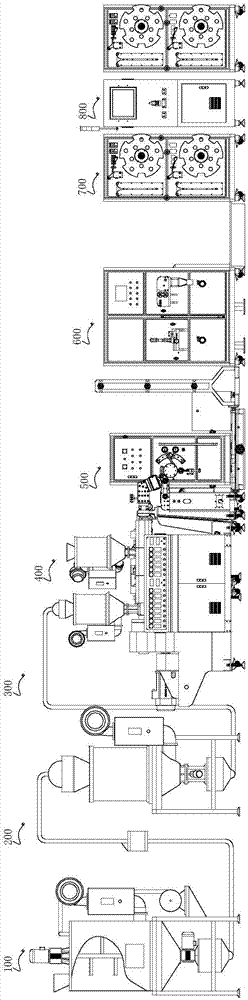

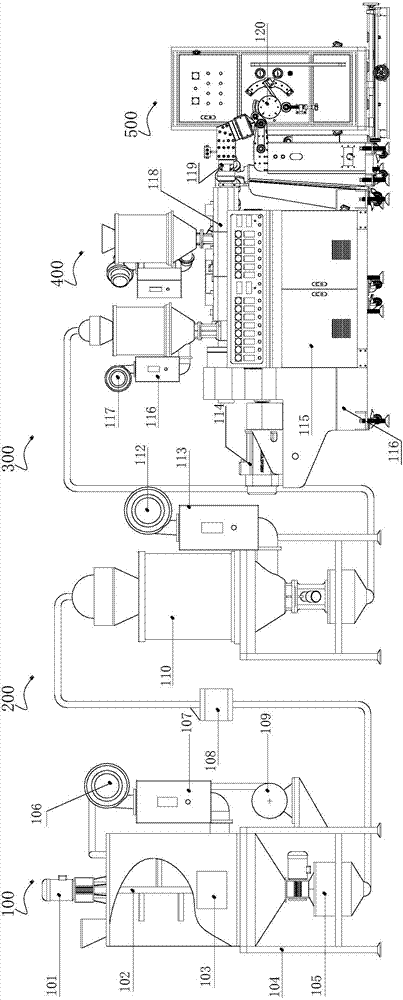

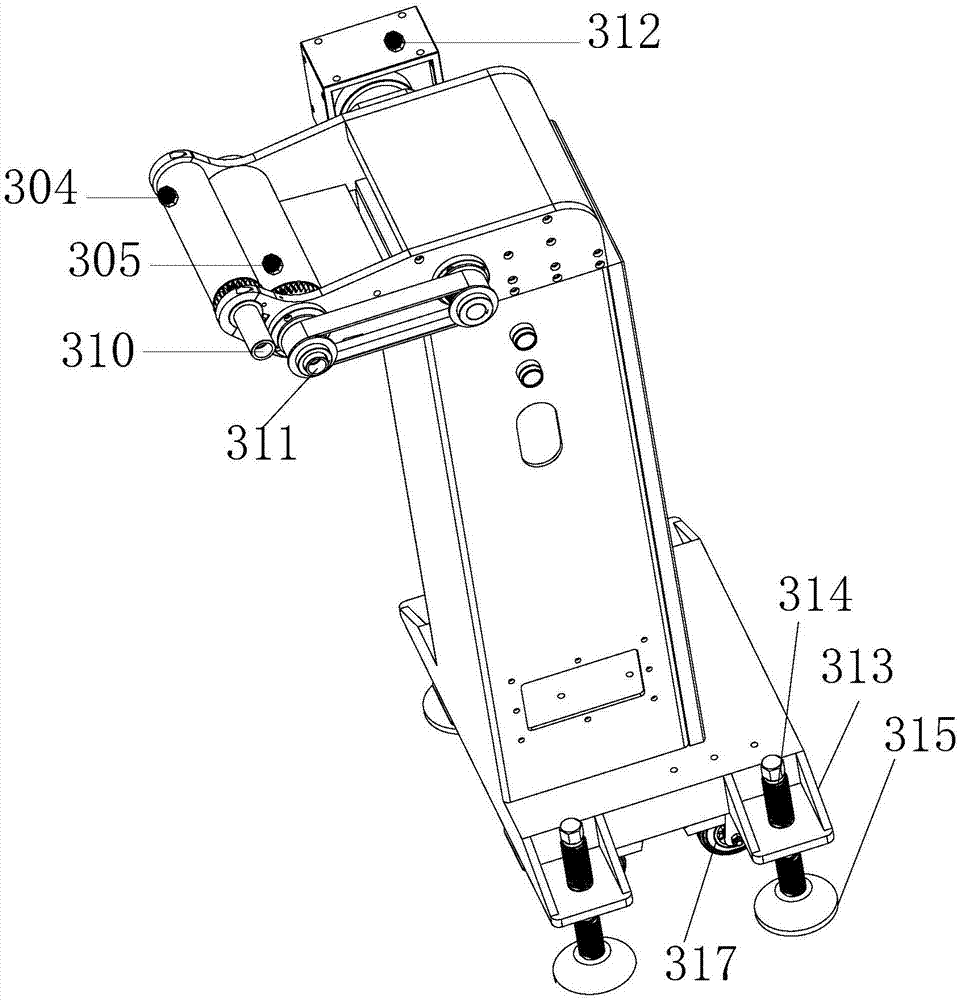

[0036] like Figure 1-7 As shown, it shows the specific implementation of the present invention. As shown in the figure, the PET carrier tape production and molding system based on the high-precision high-speed particle machine disclosed by the present invention includes a crystallization and drying assembly, an extrusion host assembly and a molding components;

[0037] The crystallization drying assembly includes a crystallization hopper assembly 100, a crystallization drying assembly 200 and a crystallization refining drying assembly 300;

[0038] Described extruding host assembly comprises extruding machine 400, and described extruding machine 400 comprises extruding main electrical box 115 and is arranged on the machine barrel assembly 118 on extruding main electrical box 115, and described machine barrel assembly 118 comprises machine barrel and is arranged on machine barrel The inner screw; the outlet of the barrel assembly 118 of the extruder 400 is provided with an extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com