Water gas mixing pipeline cleaning machine and control method thereof

A pipeline cleaning and water-air mixing technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., can solve the problems of small scouring capacity of the inner wall of the pipeline, complex structure, and failure to provide a control system to achieve cleaning Good effect, low energy consumption and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

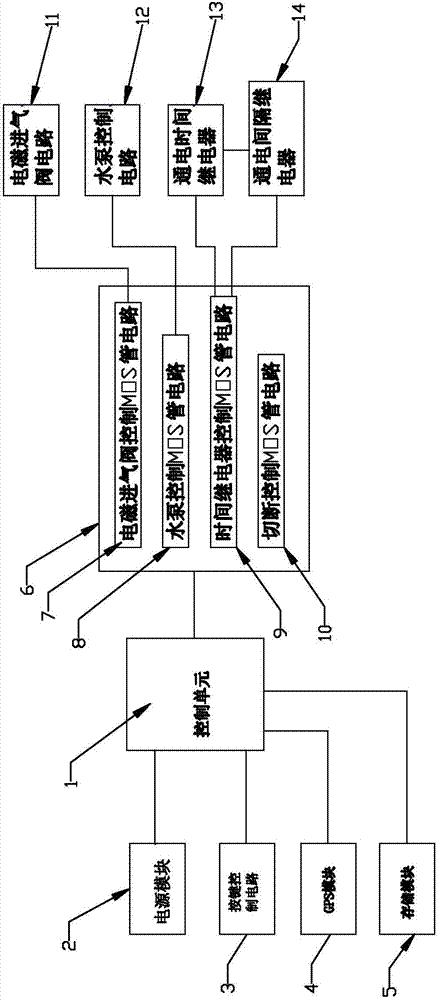

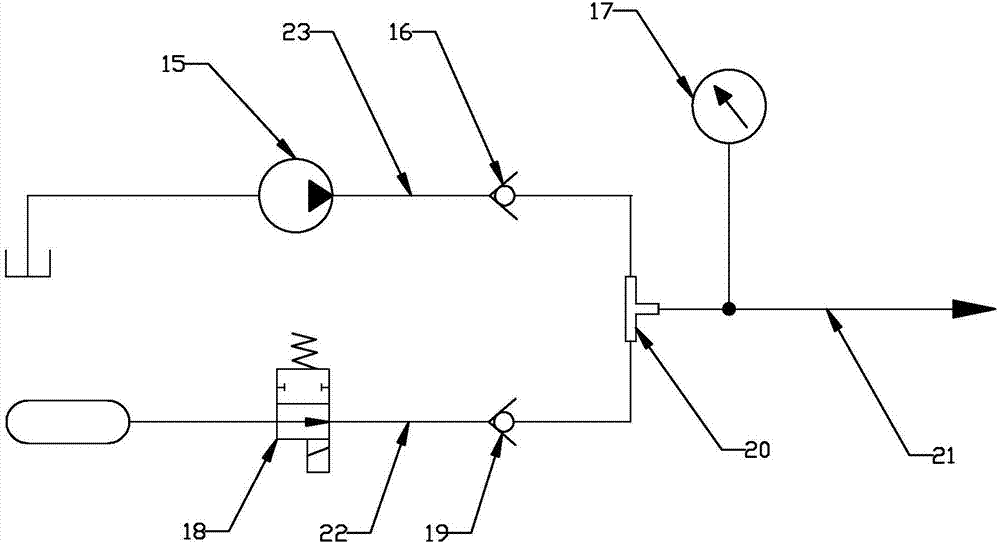

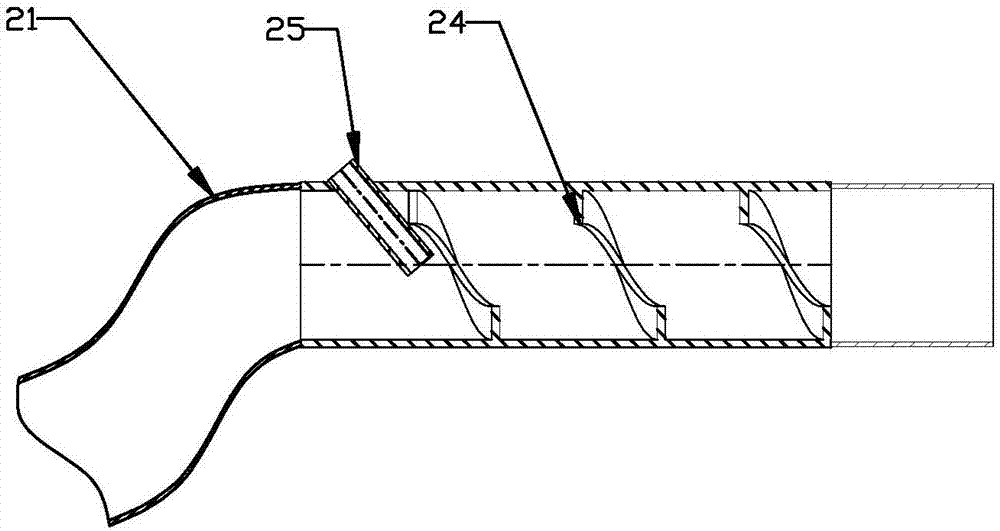

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a water-air mixed pipeline cleaning machine, including a frame, a control system, a high-pressure air pipe 22, a water pump and a corresponding cleaning liquid pipeline 23, and the high-pressure air pipe 22 and the cleaning liquid pipeline 23 pass through a The three-way 20 is connected, the outlet end of the three-way is connected with the working pipeline 21, an electromagnetic air intake valve 18 is arranged on the high-pressure air pipe, a described water pump 15 is arranged on the described cleaning liquid pipeline, and the described working pipe A section of spiral guide groove 24 is provided on the inner wall of the outlet end of the road, and a through hole is provided on the pipe wall at the rear end of the spiral guide groove. In the tangential direction of the helical guide groove, the air guide tube communicates with the gas outlet end of the electromagnetic inlet valve 18 . When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com