Air filter cleaning method and air filter cleaning machine

A cleaning machine and air filter technology, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems of physical injury to workers, increased workload, secondary pollution of dust, etc., to achieve Improve the cleaning effect, save manpower input, and reduce the loss of airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]In this embodiment, an air filter cleaning method includes the following steps: 1) putting the air filter into the air filter cleaning machine; 2) sealing the top opening and the bottom opening of the air filter, and the air filter cleaning machine is provided with a high-speed airflow jetting outward The air blowing hole extends into the inner cavity of the air filter, and the air blowing hole passes high-speed airflow from the inner cavity of the air filter to the outside of the air filter; 3) Adjust the height of the air blowing hole through the air filter cleaner, so that the high-speed airflow blows to different heights The inner wall of the air filter is rotated by the air filter cleaner, so that the blowing position of the high-speed airflow can be adjusted along the circumference of the air filter; 4) The air filter achieves the cleaning effect, and the air filter is taken out to complete the operation.

Embodiment 2

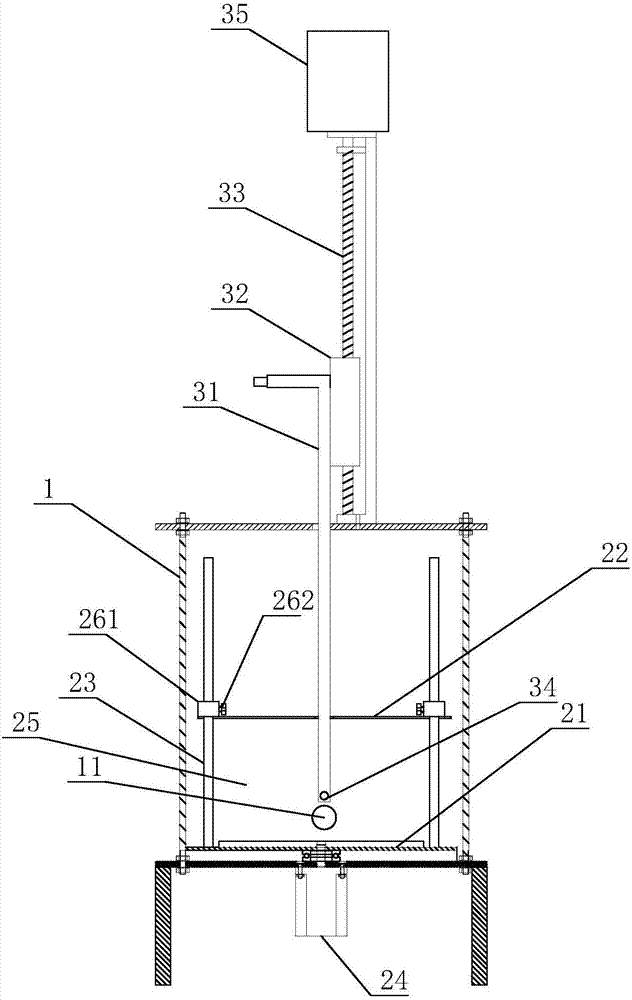

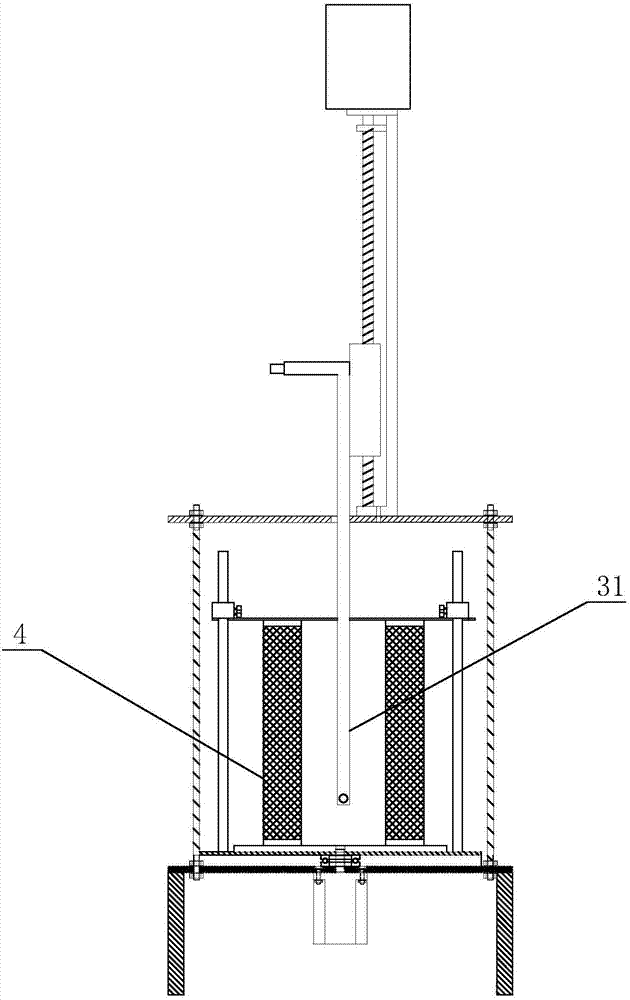

[0030] see Figure 1-Figure 2 , the air filter cleaning machine of this embodiment includes a box body 1 for accommodating the air filter 4, a rotating device for driving the air filter to rotate, and a blowing device for blowing and cleaning the interior of the air filter 4, and the rotating device includes Base plate 21, pressing plate 22, connecting rod 23 and first motor 24, described base plate 21 is installed in the casing 1 by bearing rotation, the output shaft of described first motor 24 connects base plate 21, and the lower end of described connecting rod 23 is fixed On the bottom plate 21, the pressure plate 22 is installed on the connecting rod 23, between the bottom plate 21 and the pressure plate 22 is an air filter accommodation space 25 for placing the air filter, and the blowing device includes an air source, a ventilation pipe, and an air blowing pipe 31 , movable plate 32, screw mandrel 33, nut, second motor 35, described screw mandrel 33 is vertically arrang...

Embodiment 3

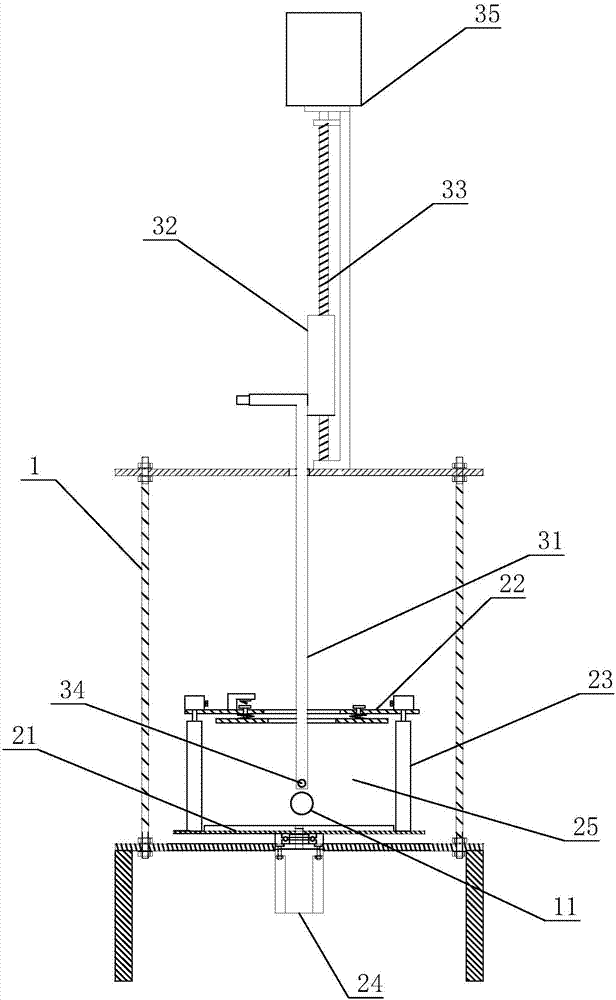

[0044] see Figure 3-Figure 5 , the air filter cleaning machine of this embodiment includes a box body 1 for accommodating the air filter 4, a rotating device for driving the air filter to rotate, and a blowing device for blowing and cleaning the interior of the air filter 4, and the rotating device includes Base plate 21, pressing plate, connecting rod 23 and first motor 24, described base plate 21 is installed in casing 1 by bearing rotation, the output shaft of described first motor 24 connects base plate 21, and the lower end of described connecting rod 23 is fixed on On the bottom plate 21, the pressure plate is installed on the connecting rod 23, and between the bottom plate 21 and the pressure plate is an air filter accommodation space 25 for placing the air filter. 32, screw mandrel 33, nut, second motor 35, described screw mandrel 33 is vertically arranged, and described screw mandrel 33 is installed on the top of casing 1 in rotation, and described nut cooperates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com