Acrylic rubber composition

A technology of acrylic rubber and composition, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of damaged anti-vibration effect and easy reduction of tanδ, and achieve the effect of improved anti-vibration and excellent tanδ value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

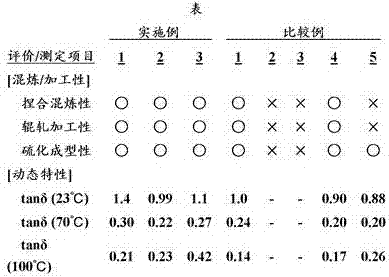

Examples

Embodiment 1

[0037] 100 parts by weight of acrylic rubber containing active chlorine groups

[0038] (UNIMATEC product Noxtite PA401-L)

[0039] Styrene resin A 20 parts by weight

[0040] (YASUHARA CHEMICAL YS RESIN SX100)

[0041] Sulfur 0.2 parts by weight

[0042] These were kneaded with a pressurized kneader, followed by roll processing with an open roll, and after vulcanization at 190°C for 8 minutes, oven vulcanization (secondary vulcanization) at 175°C for 5 hours to form a thickness of 2mm of flakes.

[0043] Kneading properties, roll workability, and vulcanization formability were evaluated, and dynamic properties (tan δ) were measured.

[0044] Mixability:

[0045] (1) When kneading with a pressurized kneader, no bridge (rubber block) is formed in the gap between the rotor and the weight, and the kneading process is carried out stably

[0046] (2) There is no pollution in the mixer after the blank is discharged

[0047] In (1) and (2), all good samples were evaluated as ◯...

Embodiment 2

[0061] In Example 1, instead of the styrene resin A, the same amount of the styrene resin B (ARUFONUP-1150 manufactured by Toa Synthetic Products) was used.

Embodiment 3

[0063] In Example 1, the styrene resin A was changed to 40 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com