Liquid sealing type vibration control device

An anti-vibration device, liquid technology, applied in the direction of shock absorber, shock absorber-spring combination, spring, etc., can solve the problems that abnormal noise cannot be sufficiently reduced, and impact sound cannot be avoided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described below with reference to the drawings.

[0034] [First Embodiment]

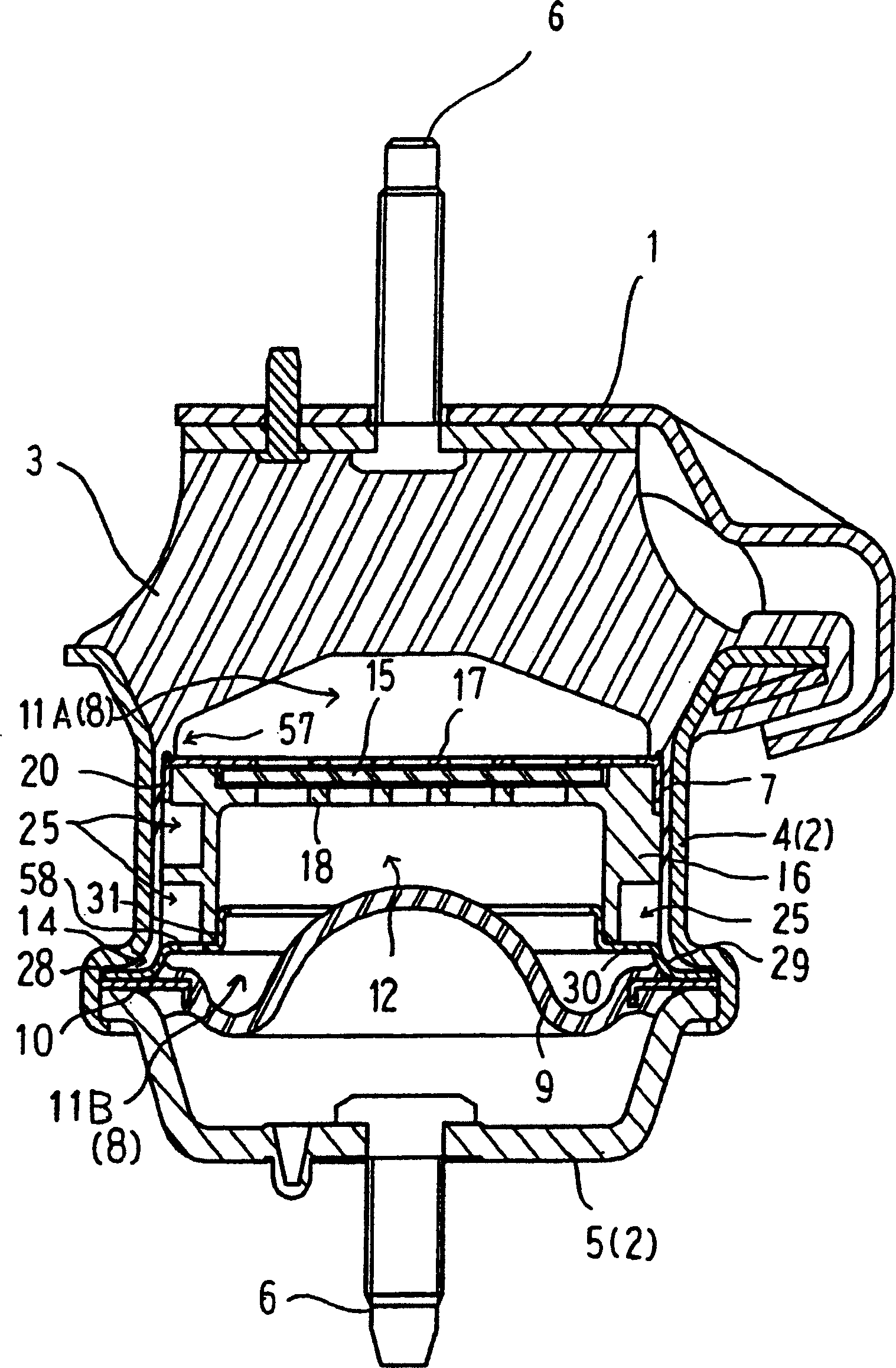

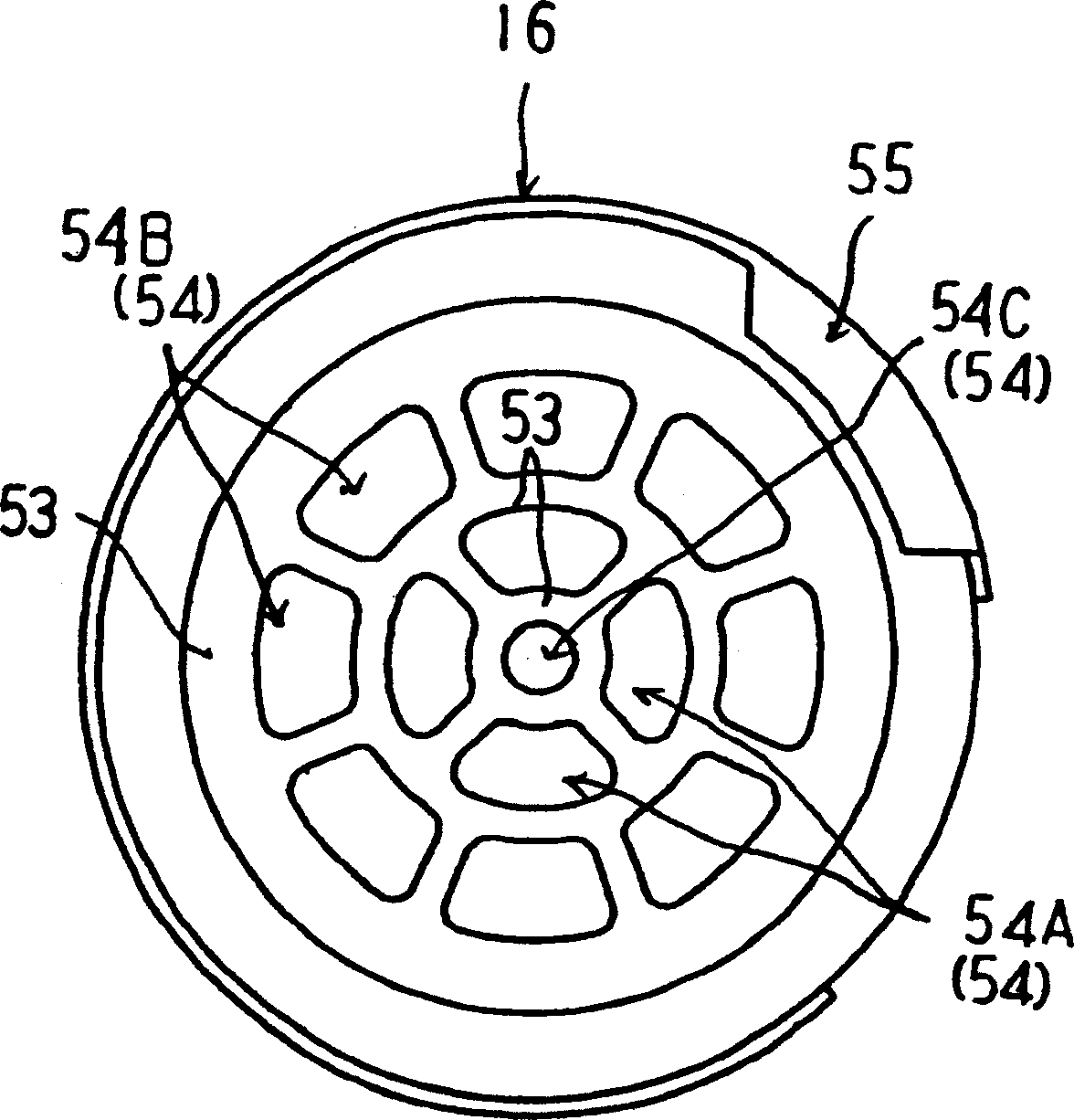

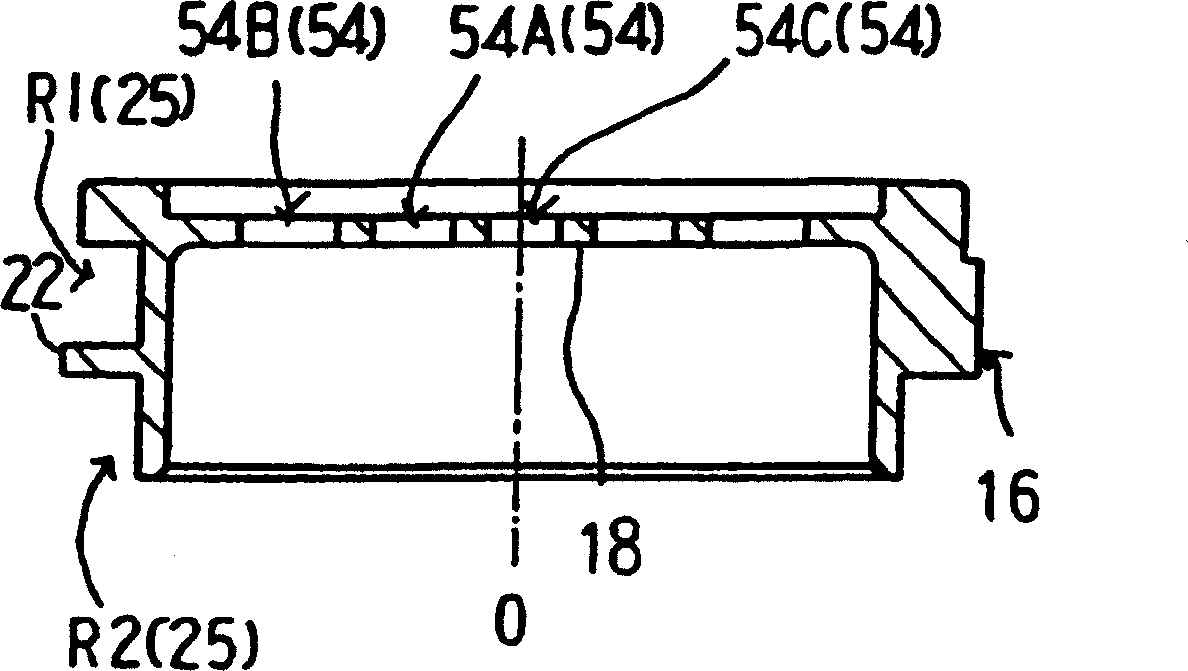

[0035] Embodiments of the present invention will be described below with reference to the drawings. figure 1 Indicates a liquid-enclosed vibration isolator. The anti-vibration device has: a first mounting part 1 installed on the automobile engine; a cylindrical second mounting part 2 mounted on the vehicle body frame below the engine; Vibration base 3.

[0036] The first attachment 1 is formed in a plate shape and has an upward attachment bolt 6 . The second mounting member 2 is composed of a cylindrical member 4 in which a vibration-proof base 3 is vulcanized, and a cup-shaped bottom member 5 , and a downward mounting bolt 6 is protruded from the center of the bottom member 5 .

[0037] The anti-vibration base 3 is formed into a conical trapezoid. And, its upper end surface is vulcanized and bonded to the first mounting member 1 , and its low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com