End-control type internal expansion type mechanical locking hydraulic oil cylinder and operation method thereof

A mechanical locking and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problems of many oil leakage points, narrow installation space, complex pipeline layout, etc., and achieve the effect of simple technical means and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

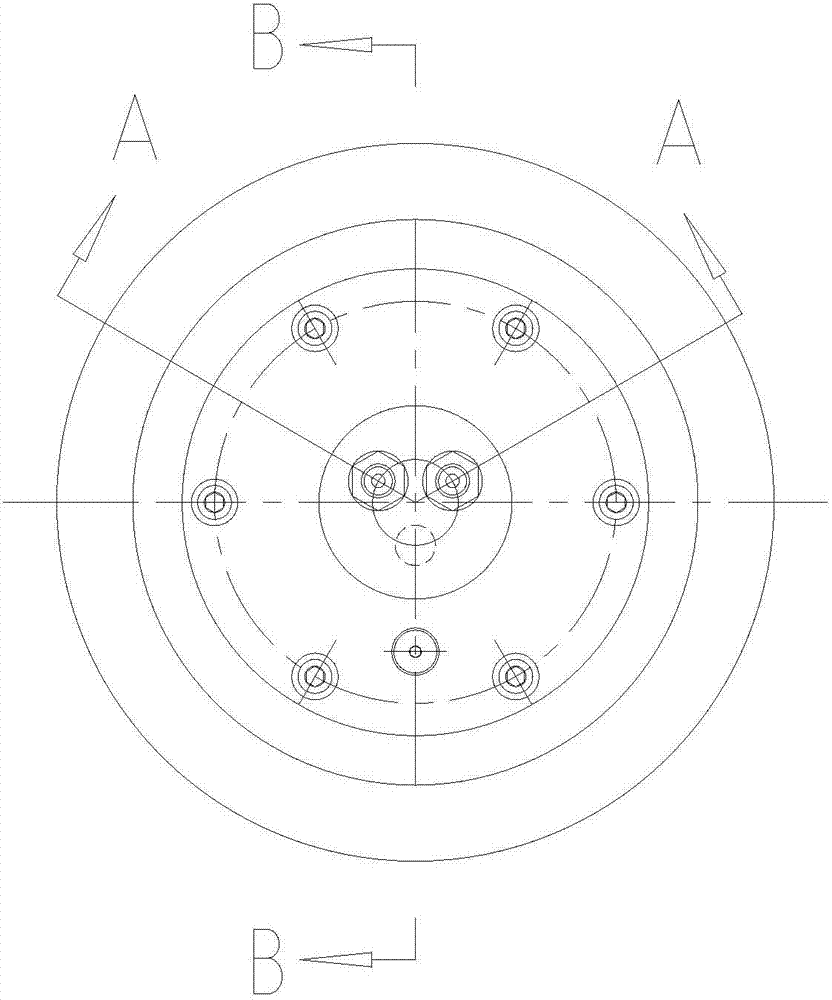

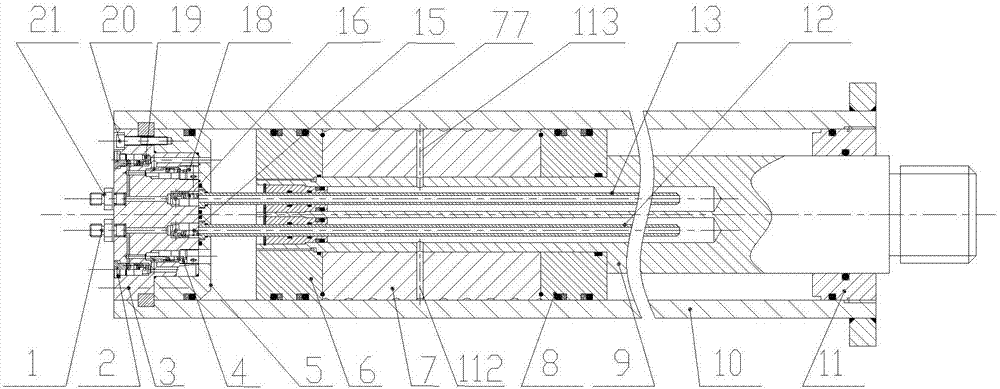

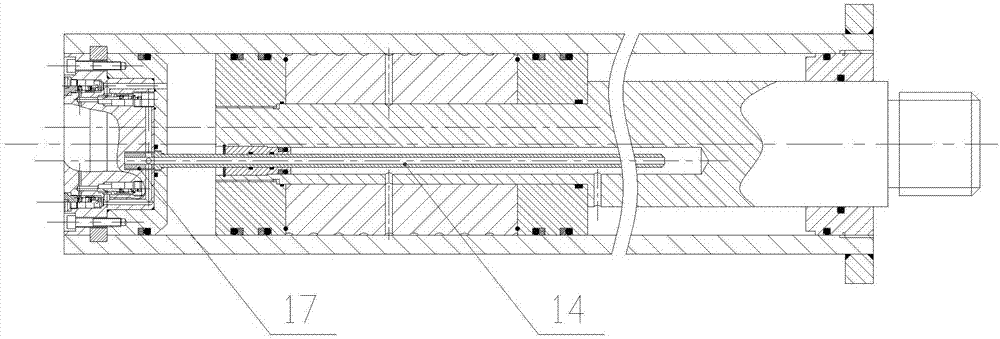

[0048] Such as Figures 1 to 4 shown. The invention discloses an end-controlled internal expansion type mechanical locking hydraulic oil cylinder, which comprises a cylinder barrel 10, a left end cover 5, a right end cover 11, and a piston rod 9; the left end cover 5 and the right end cover 11 limit the piston rod 9 to the cylinder barrel 10, and through the hydraulic oil circuit control element integrated on the left end cover 5, the action of the piston rod 9 is controlled;

[0049] Inside the piston rod 9 there are three blind oil passages with tail seals independent of each other; three oil guide rods are installed on the left end cover 5, namely the first oil guide rod 12, the second oil guide rod 13, and the third oil guide rod. Oil rod 14; these three oil guide rods are respectively placed in the corresponding blind oil passages; the third oil guide rod 14 communicates with the right oil chamber of the cylinder barrel 10, that is, the right oil chamber communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com