Integrated internal-expanding type mechanical-locking hydraulic supporting leg and operating method thereof

A technology of mechanical locking and hydraulic outriggers, applied in mechanical equipment, transportation and packaging, fluid pressure actuating devices, etc., can solve problems such as many oil leakage points, narrow installation space, and complicated pipeline layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

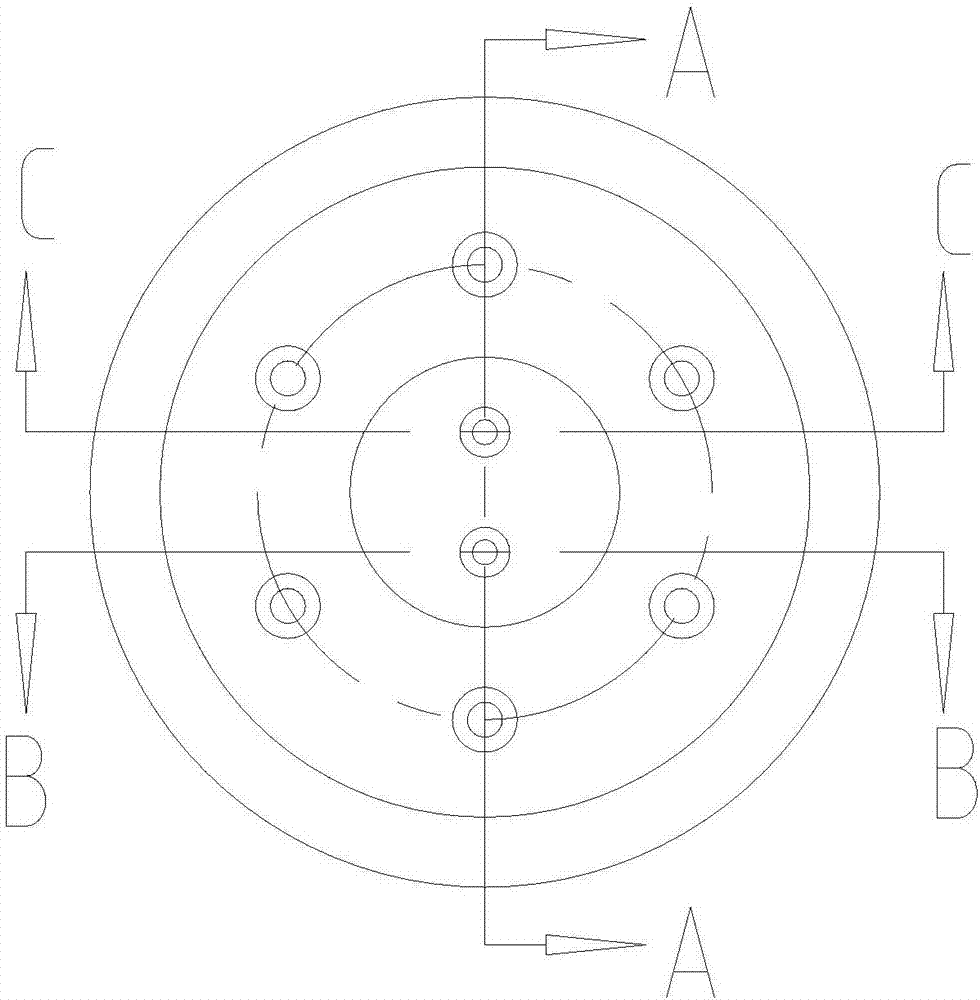

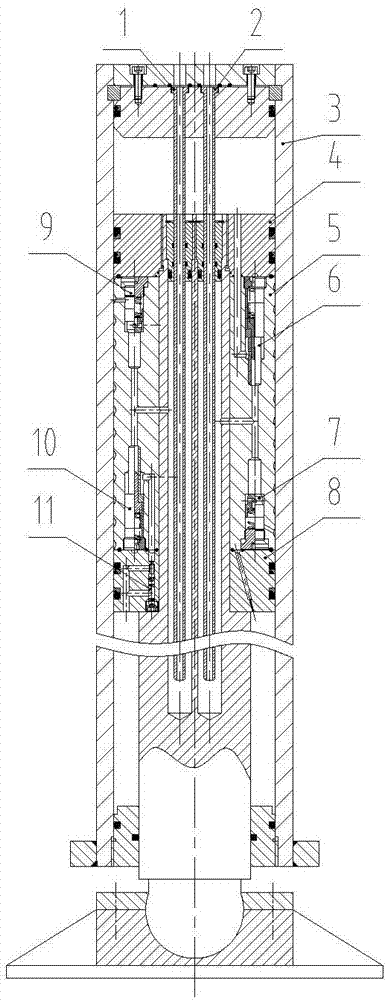

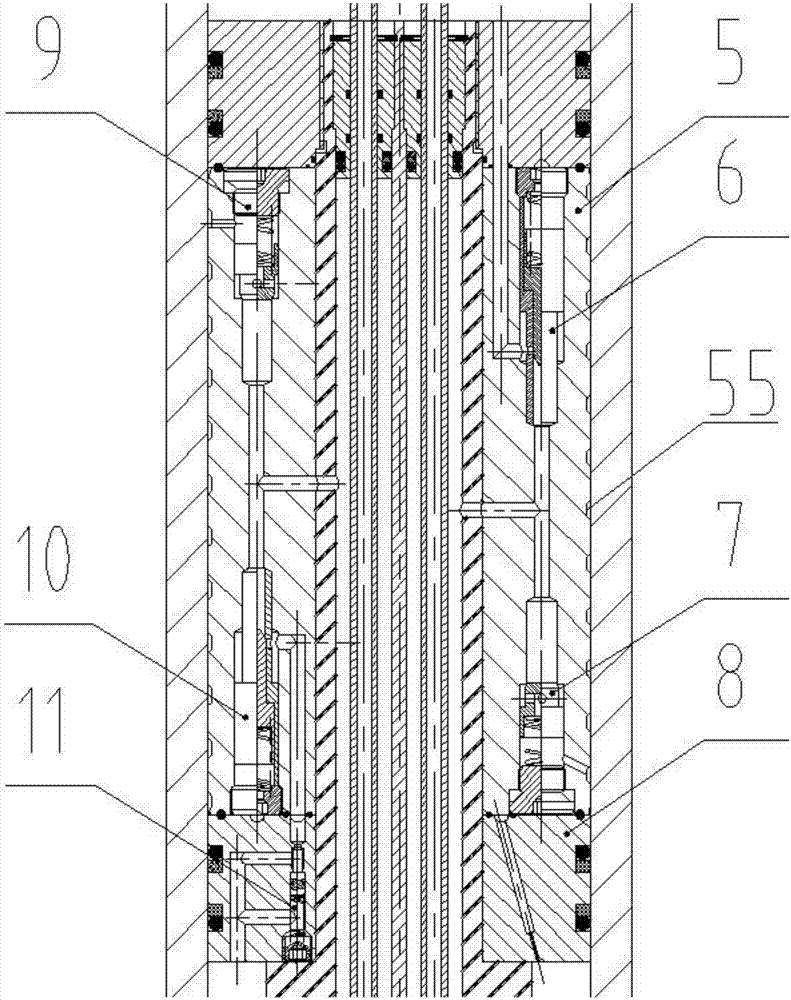

[0048] Such as Figures 1 to 8 shown. The invention discloses an integrated internal expansion type mechanical locking hydraulic outrigger, which includes a cylinder 3 and a piston rod 15 inside which also serves as a support; the piston rod 15 is controlled to perform telescopic movement through a hydraulic oil circuit control element; The piston of the piston rod 15 is divided into an upper end cover piston 4, a spiral sleeve 5 and a lower end cover piston 8; the upper end cover piston 4 is fixed on the piston rod 15 through threaded connection, and the lower end cover piston 8 and the spiral sleeve 5 are respectively set on the piston on the rod 15; the spiral sleeve 5 is limited and clamped between the upper end cap piston (4) and the lower end cap piston (8);

[0049] The outer circumferential surface of the spiral sleeve 5 is provided with a spiral groove cavity 55; the inside of the piston rod 15 is axially symmetrically opened with two oil guide holes; the first oil g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com