Hydrostatic-permanent magnet dual-suspension bearing guide rail system

A guide rail system and static pressure technology, applied in the field of machine tool guide rails, can solve problems such as the influence of load distribution and elastic deformation of the guide rail system, and achieve the effects of improving poor machining accuracy, improving bearing capacity and stiffness, and increasing the effective bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

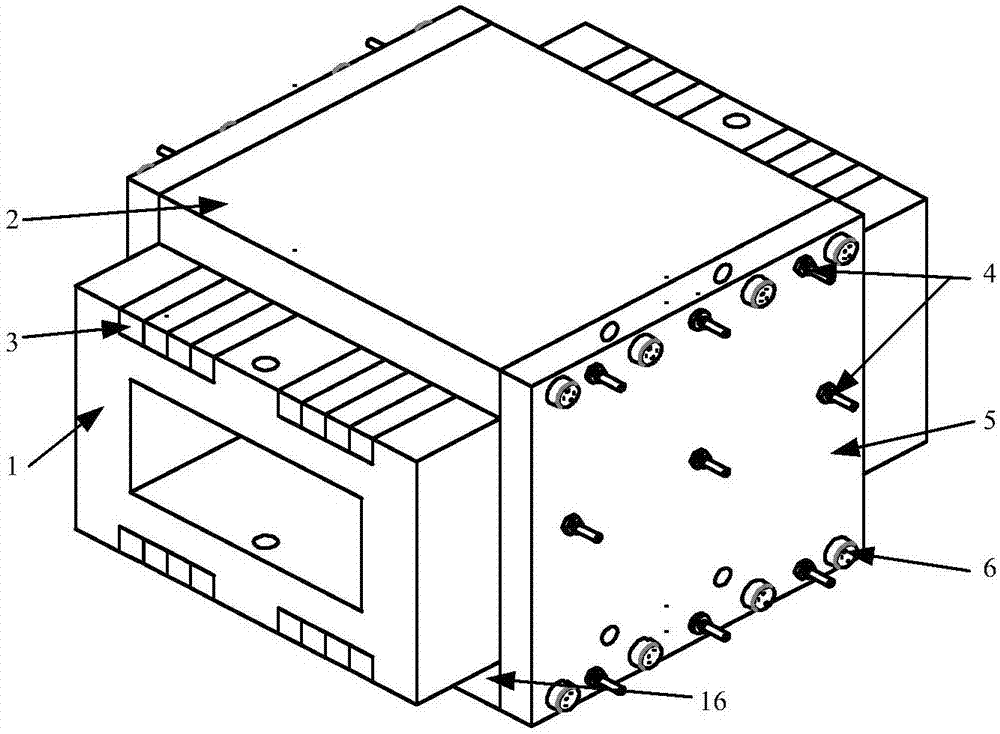

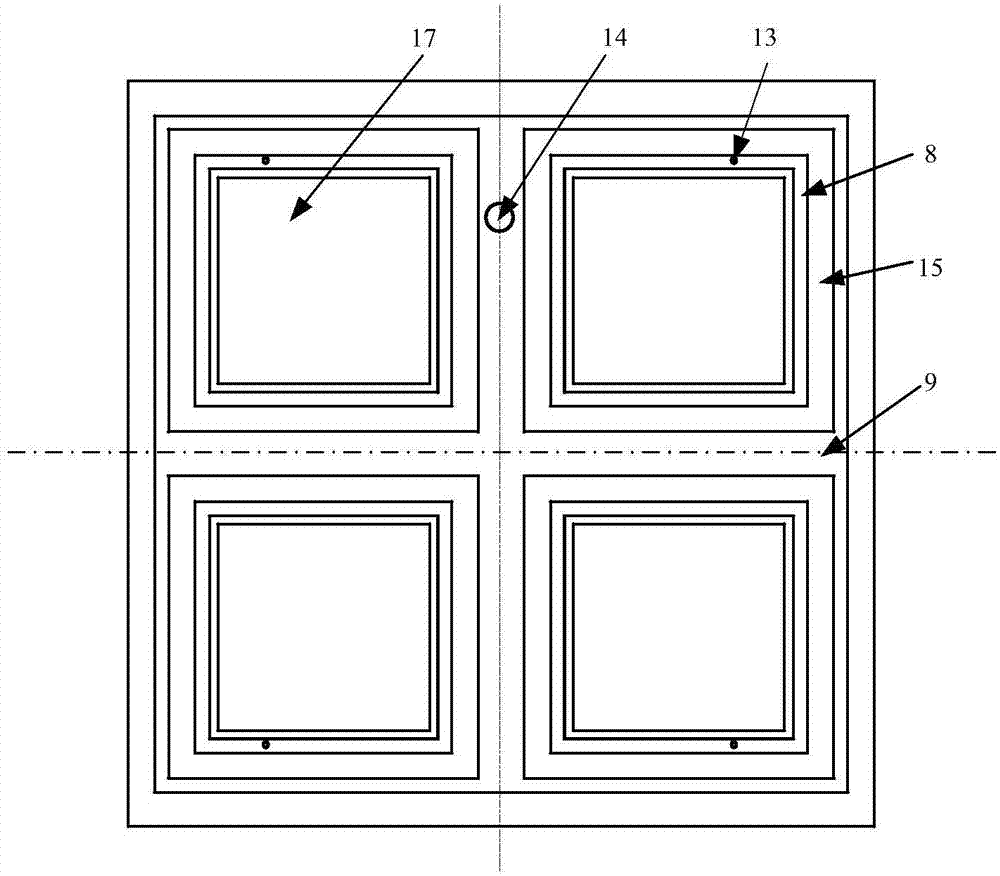

[0022] exist figure 1 with figure 2 In the static pressure-permanent magnetic dual-suspension support guide rail system perspective schematic diagram shown, the four guide rail grooves 27 above and below the existing guide rail 1 are all provided with permanent magnet strips A3 that fill up each groove, and their length and height They are all the same as the groove, and the sum of the widths of the four permanent magnet strips is less than or equal to the width of the guide rail groove. The upper, lower and both sides of the guide rail and the permanent magnet bar are respectively provided with static pressure guide plates surrounding it, and the upper static pressure guide plate 2 and the lower static pressure guide plate 16 are symmetrical to the horizontal plane passing the center line of the guide rail, while the static pressure guide plates on both sides The guide plate 5 is then symmetrical with the vertical plane crossing the center line of the guide rail. There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com