Gravel production gradation adjustment device

An adjustment device and grading technology, applied in the directions of transportation and packaging, conveyor objects, solid separation, etc., can solve the problems of narrow application occasions, few classifications, inability to complete automatic batching, etc., to achieve wide application range, large selectivity, The effect of improving the quality of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

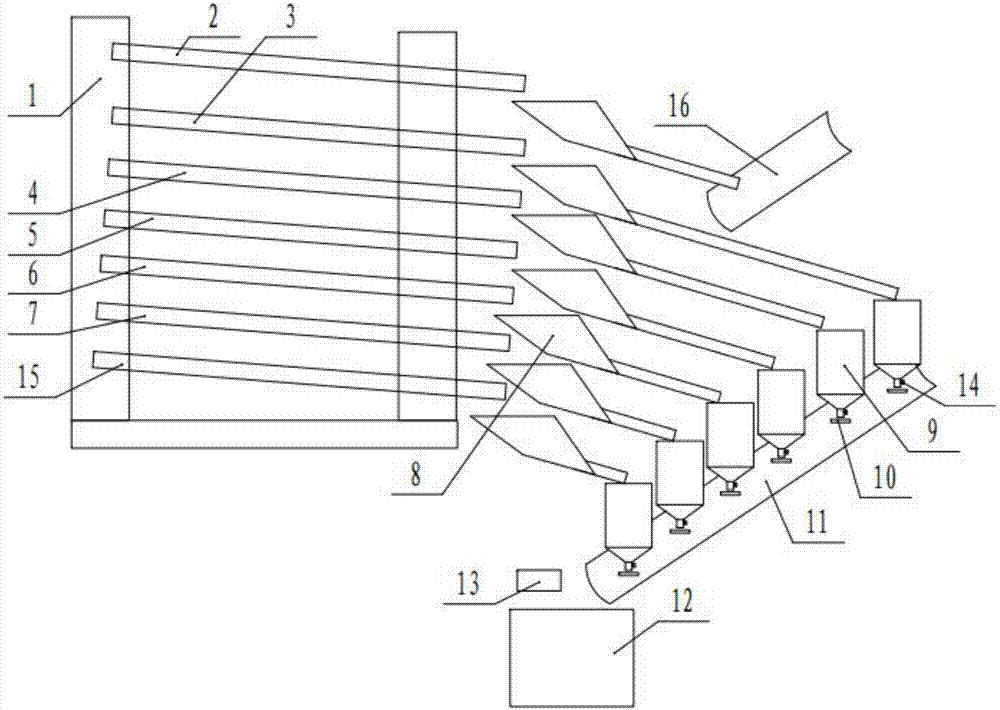

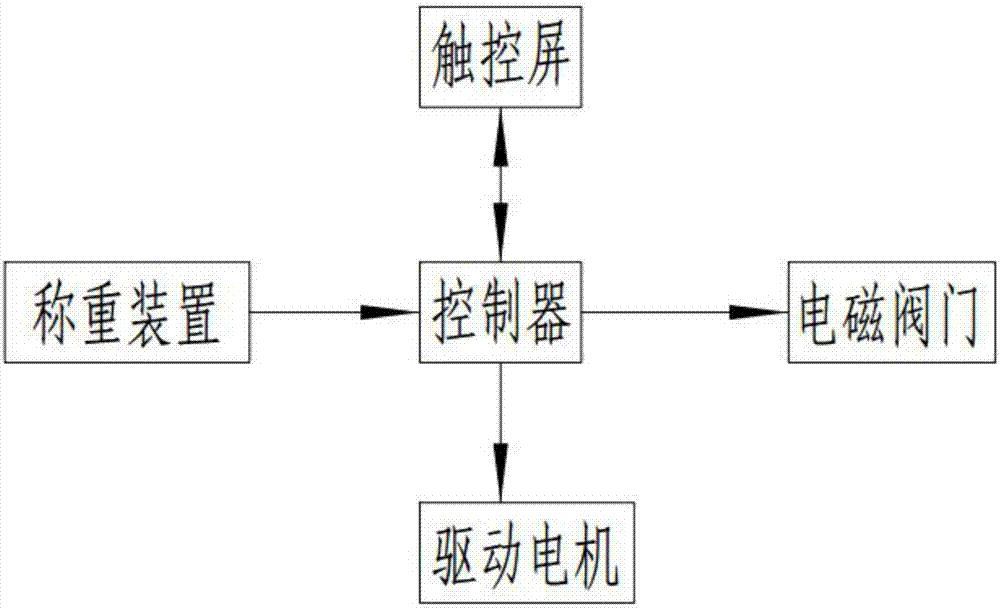

[0012] Embodiment 1: as Figure 1-Figure 2 Shown, a kind of gravel production gradation adjusting device comprises grading screen 1, and grading sieve 1 comprises multi-layer screen cloth, is provided with the screen cloth of 4.75mm mesh diameter-2, 3mm mesh diameter successively from top to bottom. Screen two 3, 1.25mm mesh diameter three 4, 0.25mm mesh diameter four 5, 0.16mm mesh diameter five 6, 0.075mm mesh diameter six 7 and set Material conveying hopper 15, each layer of screen cloth and collecting material conveying hopper 15 discharging ends are connected to each collecting hopper, and the collecting hopper 8 that top layer screen mesh is connected is connected to recovery conveyer belt 16, and all the other collecting hoppers 8 are connected to by pipeline. A feed bin 9, a weighing device 10 is arranged at the outlet of the feed bin 9, and a belt conveyor 11 is arranged in front of the weighing device 10, and the discharge end of the belt conveyor 11 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com