Lithium resource recycling method on waste lithium ion battery negative plate

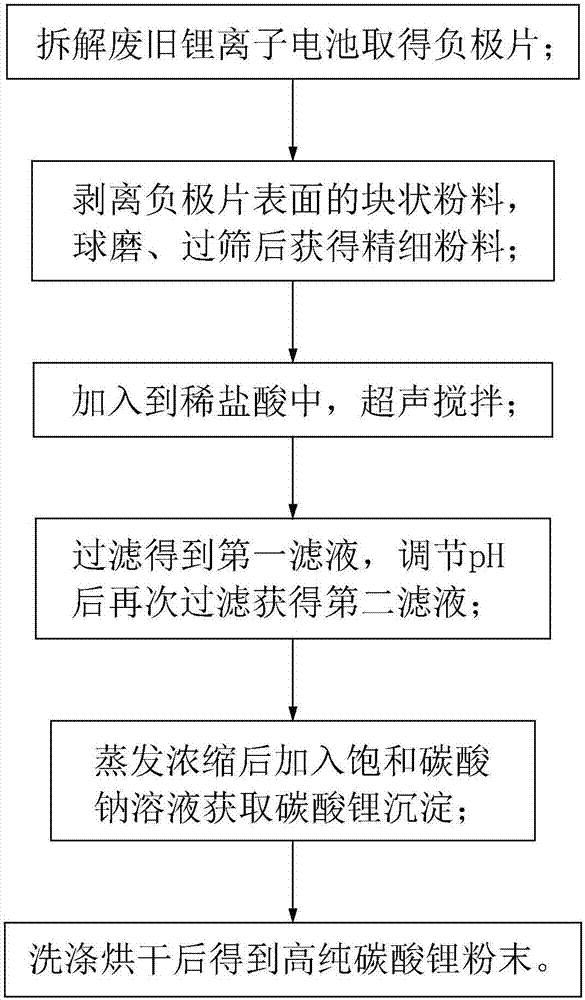

A lithium-ion battery and resource recovery technology, which is applied in the field of lithium resource recovery on the negative electrode of waste lithium-ion batteries, can solve the problems of waste of lithium resources, environmental pollution, etc., and achieve the effects of low cost, improved economic value, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

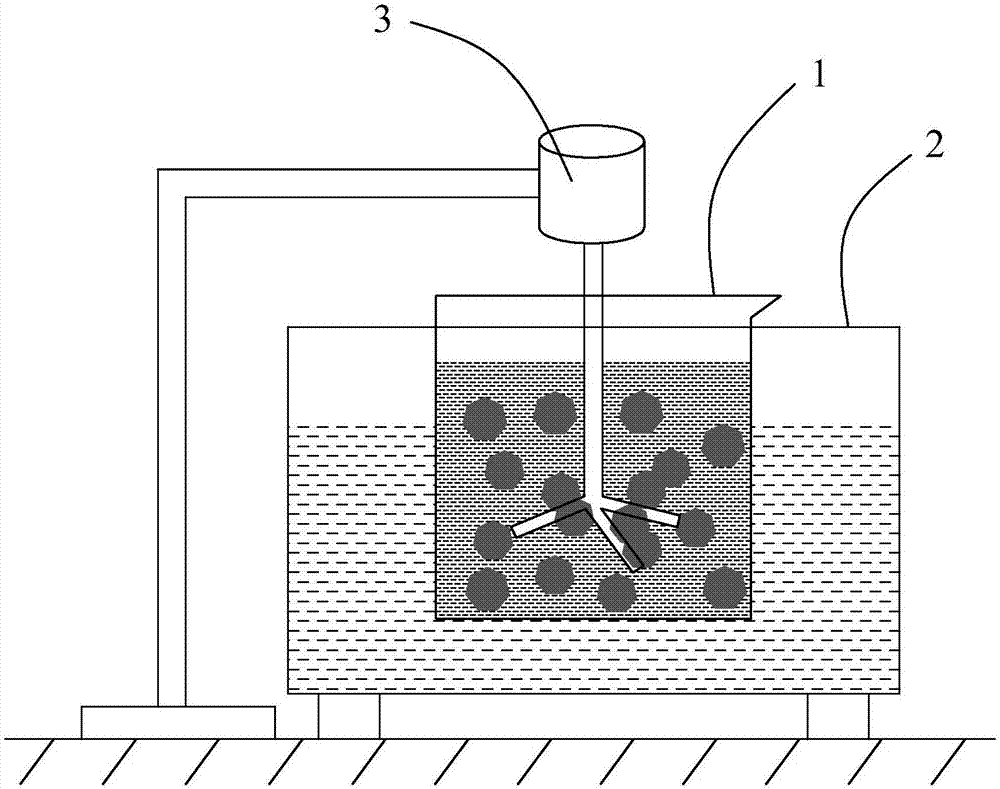

[0029] Peel off the bulk powder on the surface of the negative electrode sheet obtained after dismantling the waste lithium-ion battery, and pass through a 200-mesh sieve after ball milling to obtain a fine powder; then add the fine powder to a sufficient amount of 3mol / L Ultrasonic stirring in dilute hydrochloric acid. see figure 2 The devices required for ultrasonic stirring include a glass container 1, an ultrasonic cleaning machine 2 and a stirrer 3. Specifically, dilute hydrochloric acid and fine powder are contained in a glass container 1, and the glass container 1 is placed in the ultrasonic cleaning machine 2. In the water tank, clamps are used to fix the glass container 1 to prevent it from shaking greatly, and the stirring paddle of the stirrer 3 can extend into the inside of the glass container 1 . In this embodiment, the ultrasonic power of the ultrasonic cleaner 2 is 400W, the stirring rate of the agitator 3 is 50r / min, and the ultrasonic stirring time is 20min....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com