Hall product testing mechanism and assembling and testing method

A technology for product testing and test pieces, which is applied in the direction of measuring devices, measuring magnetic variables, instruments, etc., can solve problems such as easy material stacking, left and right deviation, and insufficient stability of the magnetic field, so as to improve production efficiency, reduce lifting range, and external interference Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

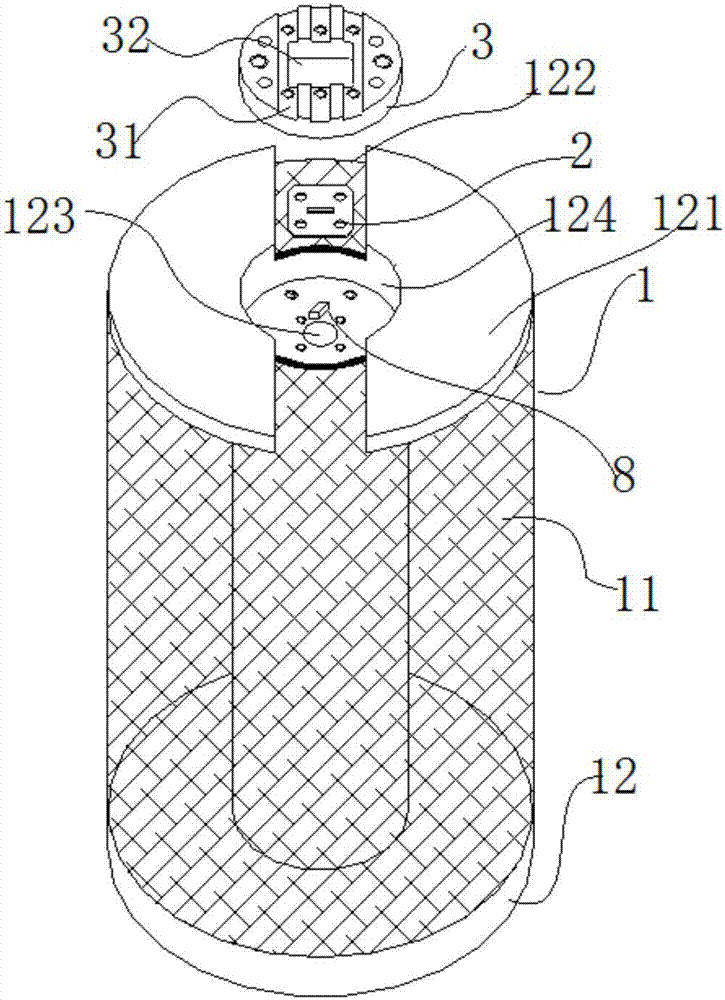

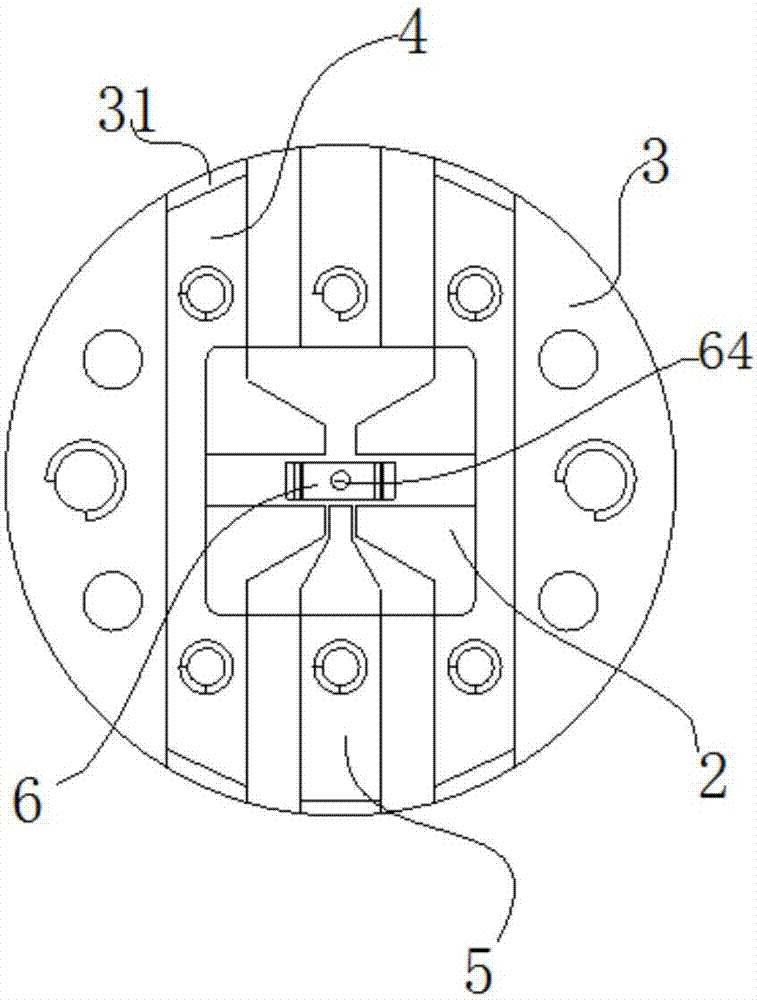

[0064] The Hall product testing mechanism of the present embodiment, such as figure 1As shown, it includes a Hall coil 1, a collar 2, a base 3, a Hall test piece and a Hall test clip; the Hall coil 1 includes an I-shaped support 12 and an enameled wire coil wrapped in the middle part of the I-shaped support 12 11. One end of the I-shaped bracket 12 is a ring platform 121, and the center of the ring platform 121 is a circular groove 124; the center of the circular groove 124 is a circular through hole 123, which can place 8 products to be tested Into the circular groove 124 for detection, during detection, the external interference received is reduced, and a stable magnetic field is provided; the base 3 is circular, embedded in the circular groove 124, and the Hall test piece fixed on the upper surface of the base 3; as Figure 4 As shown, the middle of the base 3 is a square collar positioning hole 32, and the collar 2 is embedded in the collar positioning hole 32; as Figu...

Embodiment 2

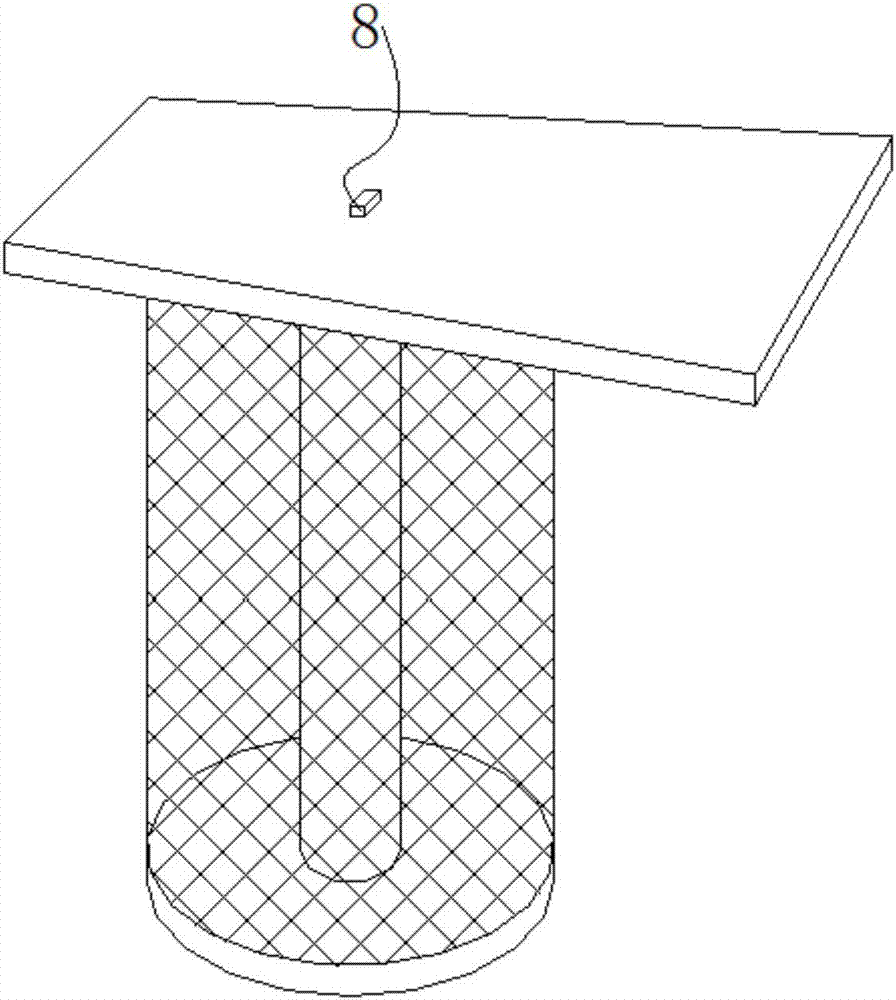

[0068] The Hall product testing mechanism of this embodiment, the basic structure is the same as that of Embodiment 1, the differences and improvements are: the Hall test clip is improved to the Hall movable clip 6; the depth of the circular groove 124 is not less than the base 3, the Hall The sum of the thicknesses of the test piece and the product to be tested 8, so as to ensure that the product to be tested 8 can not protrude from the circular groove 124, thereby ensuring the stability of the test magnetic field; Figure 15 , 16 As shown, the Hall movable clip 6 includes a fixed clip 61, a movable clip 62, a connecting rod 65 and a base 610; The rotation of the clip 61 realizes the width adjustment of the jaw 6111 between the two; the bottom of the fixed clip 61 is fixed with a connecting rod 65; just below the connecting rod 65, a base 610 with a blind hole 6101 is provided, the connecting rod 65 and The blind hole 6101 fits with the upper and lower gaps, and moves up and...

Embodiment 3

[0070] The Hall product testing mechanism of present embodiment, basic structure is the same as embodiment 2, difference and improvement are: as Figure 10 , 11 , 12, on the ring platform 121, there are two left and right symmetrical slots 122 outwards from the circular groove 124, which provide the passage for the product 8 to be tested; the rotating device is a fixed clip 61, a movable clip 62 are provided respectively on the respective side faces facing each other with a convex semi-cylinder 612 and a concave semi-cylindrical 622; The convex semi-cylinder 612 is pivoted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com