Dyeing mark bullet

A technology of marking and dyeing agent, applied in the field of dyed marking bullets, can solve the problems of unfavorable fast marking, slow release of dyeing agent, waste of working time, etc., and achieve the effect of expanding the marking area and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

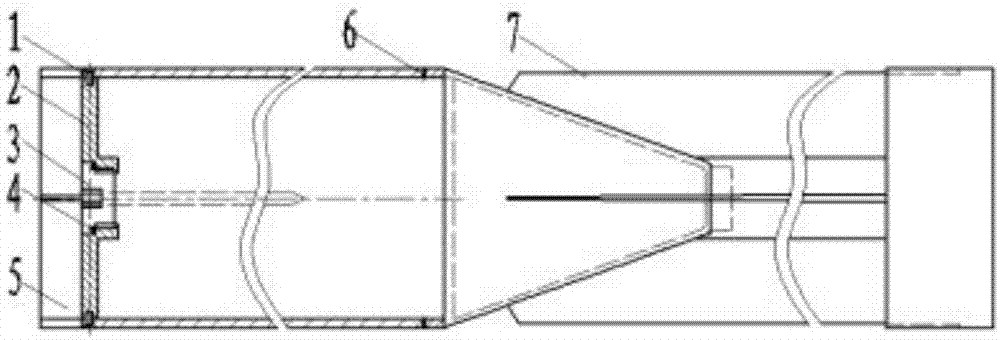

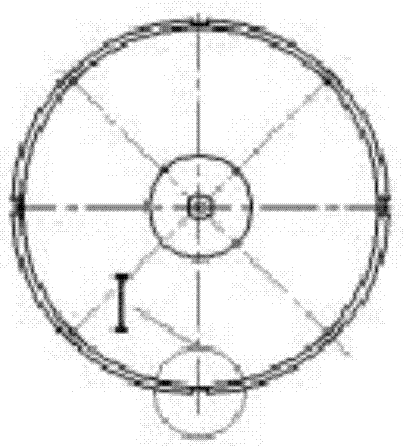

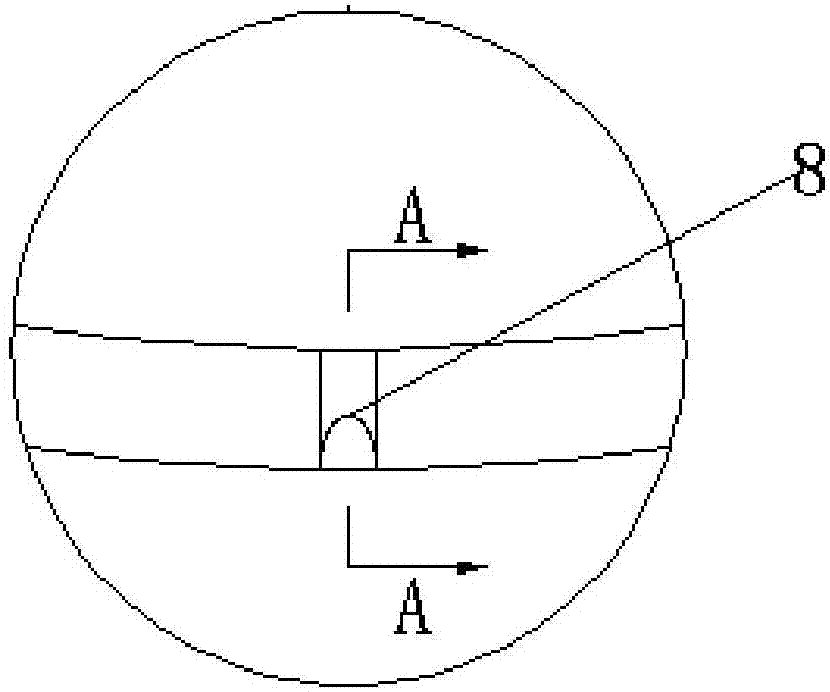

[0022] see Figure 1~4 , a kind of dyeing mark projectile, comprises the projectile body 5 that one end is connected with control fin 7, the other end opening of described projectile body 5, the end cap 2 that is used for sealing projectile body 5 lumen dyeing agent is plugged in its opening, described The outer wall of the body 5 is provided with an explosion-induced cracking groove 8; the explosion-induced cracking groove 8 is divided into two connected parts, wherein the part far away from the control empennage 7 is an opening section, and the other section is a half-opening section, and the opening section is fully opened and closed. Extending to the port, the depth of the half-open section is lower than the thickness of the outer wall of the body 5 .

[0023] In the present invention, after the dyed marker projectile is launched, the bottom of the projectile body 5 impacts and is first broken. Simultaneously with breaking, the bursting and cracking grooves are opened out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com