Forage grass drying device

A technology for drying forage and drying cylinder is applied in drying, dryer, grass drying and other directions, which can solve the problems of inability to form an automatic production line, large power required for rotation, uneven drying of forage, etc., and achieves a simple structure. , easy to operate, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

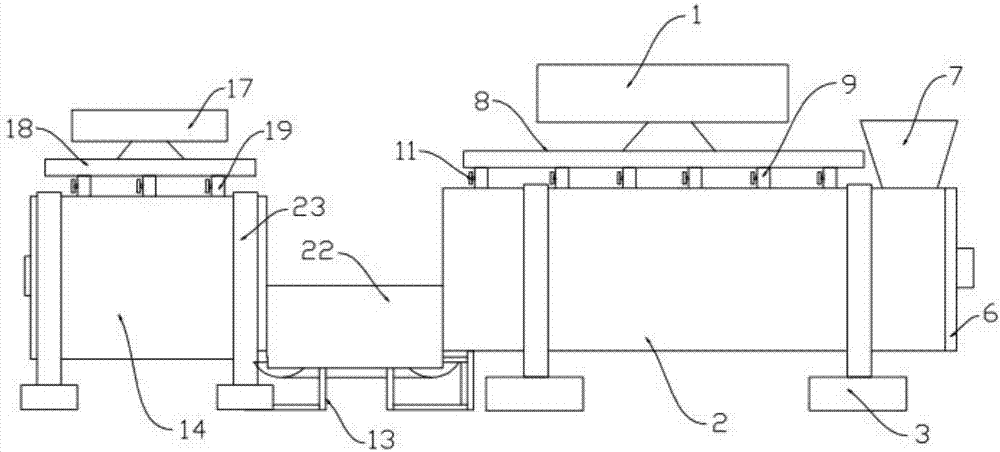

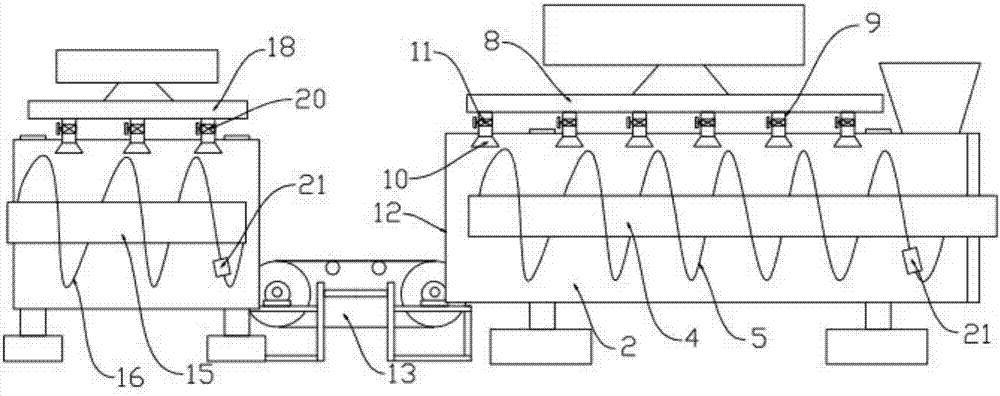

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] In conjunction with the accompanying drawings, a pasture drying device includes a hot air blower 1, a drying cylinder 2 in a cylindrical structure, and a support frame 3. The drying cylinder 2 is provided with a rotating shaft 4, and the rotating shaft 1 4 is provided with a helical piece 5, and the described helical piece 5 is a grid structure, and one end of the drying cylinder 2 is provided with a baffle plate 6, and the end of the baffle plate 6 is located on the described drying cylinder 2. A feed hopper 7 is provided at the top, and a hot blast main pipe 8 is connected to the outlet of the hot air blower 1. The hot blast pipe 8 is provided along the length direction of the drying cylinder 2, and the hot blast pipe 8 is provided with There is a hot air branch pipe 9 that goes deep into the drying cylinder 2. The end of the hot air branch pipe 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com