Multi-fuel combustor

A burner and multi-fuel technology, which is applied in the direction of burning various fuels, solid fuels, block fuels and liquid fuels, etc. It can solve the problems of reducing production costs, incomparable heat energy release, and low combustion quality and other issues to achieve the effect of increasing profit margins, simple and scientific design, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following specific examples will be used to describe the present invention in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

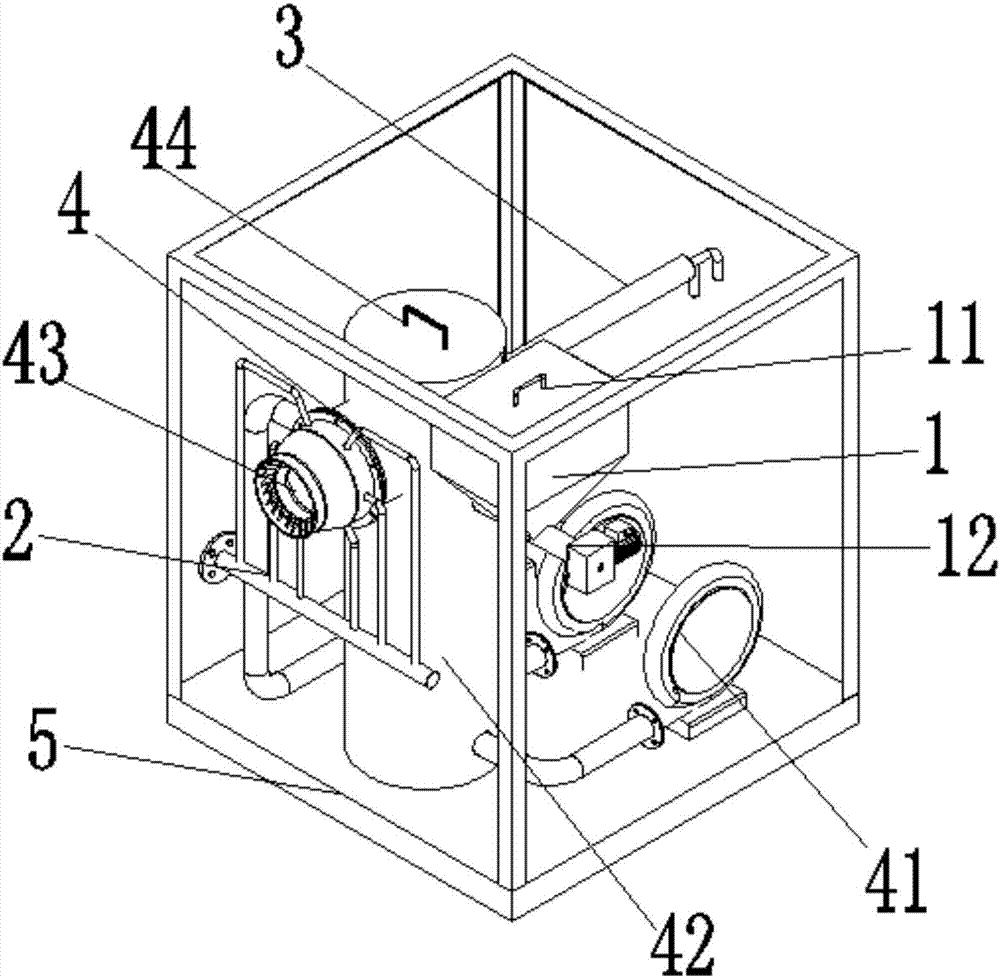

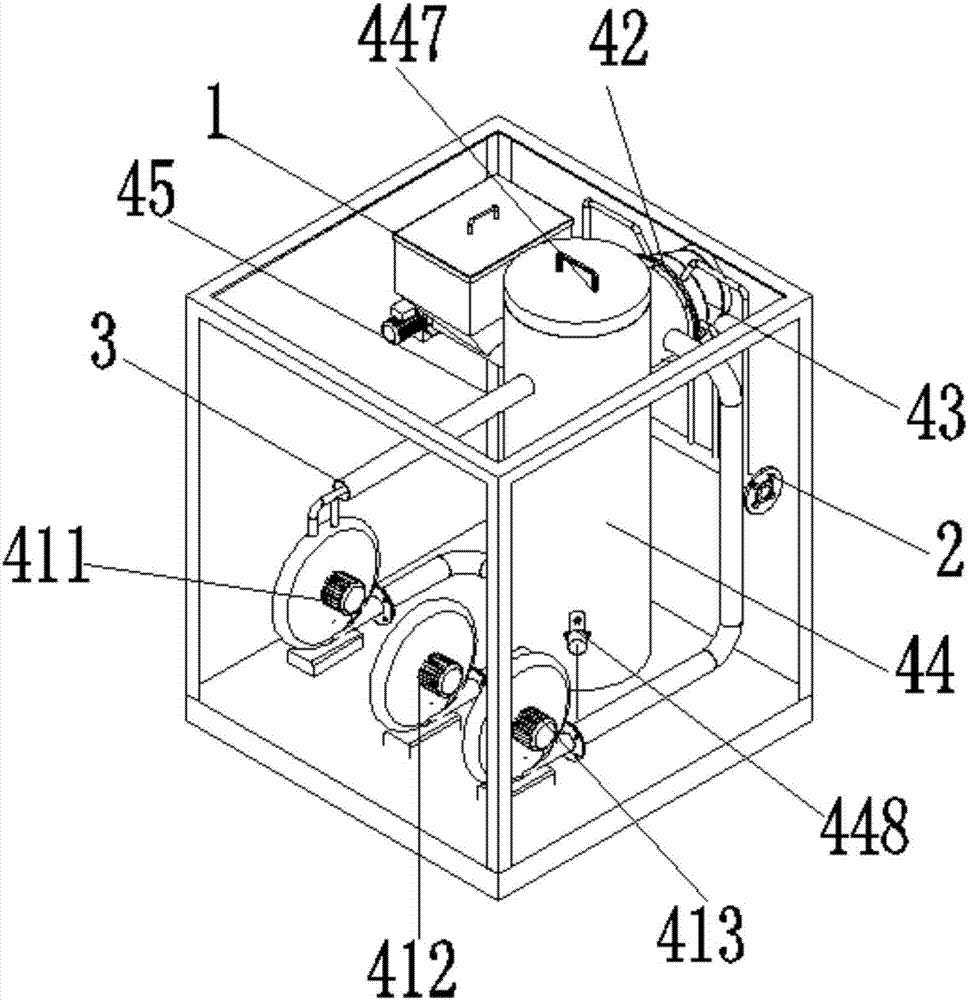

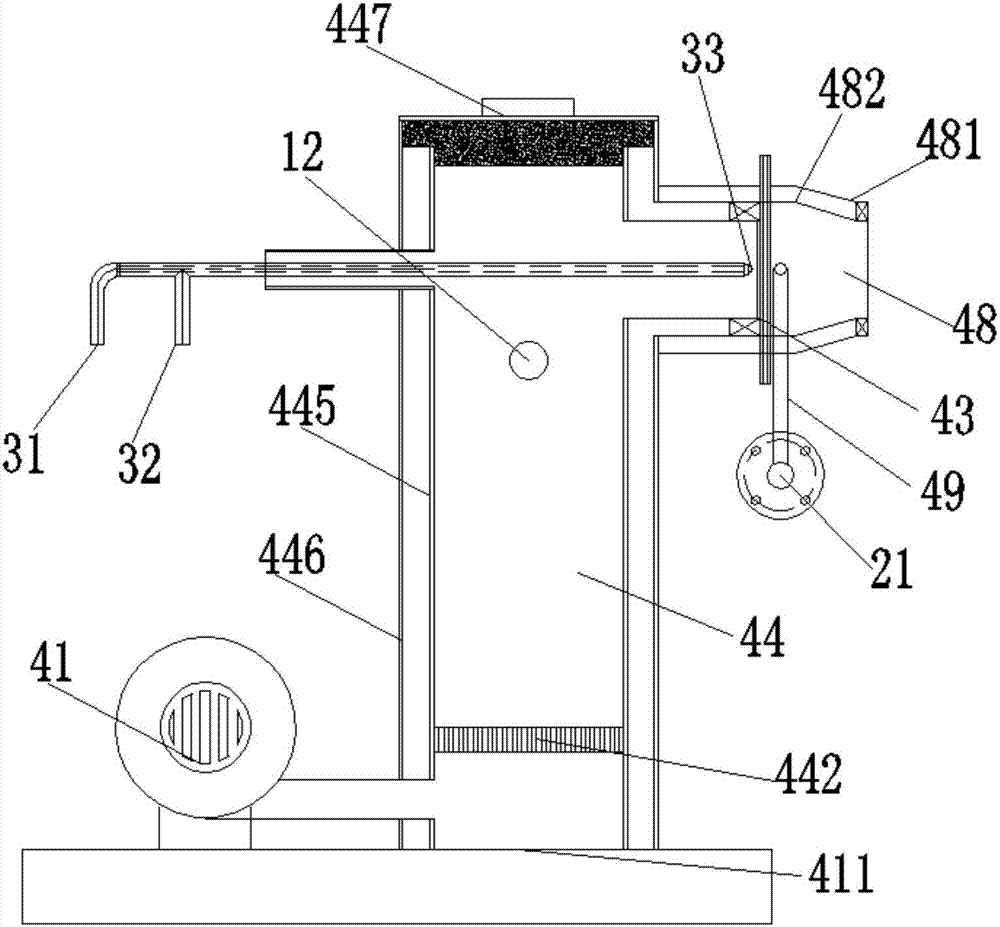

[0025] Such as Figure 1 to Figure 5 As shown, a multi-fuel burner includes a biomass gas mechanism 1, a natural gas mechanism 2 and a light fuel oil mechanism 3, and a fuel combustion device 4 connected to the biomass gas mechanism 1, the natural gas mechanism 2 and the light fuel oil mechanism 3 respectively , these are all arranged on the base in the cabinet 5 frame body with protective cover; The connected burner head 43 and the fire viewing pipe 45 located outside the combustion chamber 44, the light fuel oil mechanism 3 passes through the fire viewing pipe 45 and enters the combustion chamber 44; the combustion burner head 43 is provided with several wind swirls 46 and connecting pipes 47, and wind cone 48, gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com