Drainage method of non-cell-cementation cased-hole-completion coal bed gas horizontal well

A technology for horizontal wells and coalbed methane, applied in wellbore/well components, production fluids, earthwork drilling and production, etc., can solve unqualified cementing quality, cement slurry polluted coal seam, clean water sand-carrying fracturing scale and sanding intensity Minor problems, good drainage and gas recovery, low production and operation costs, and good fracturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

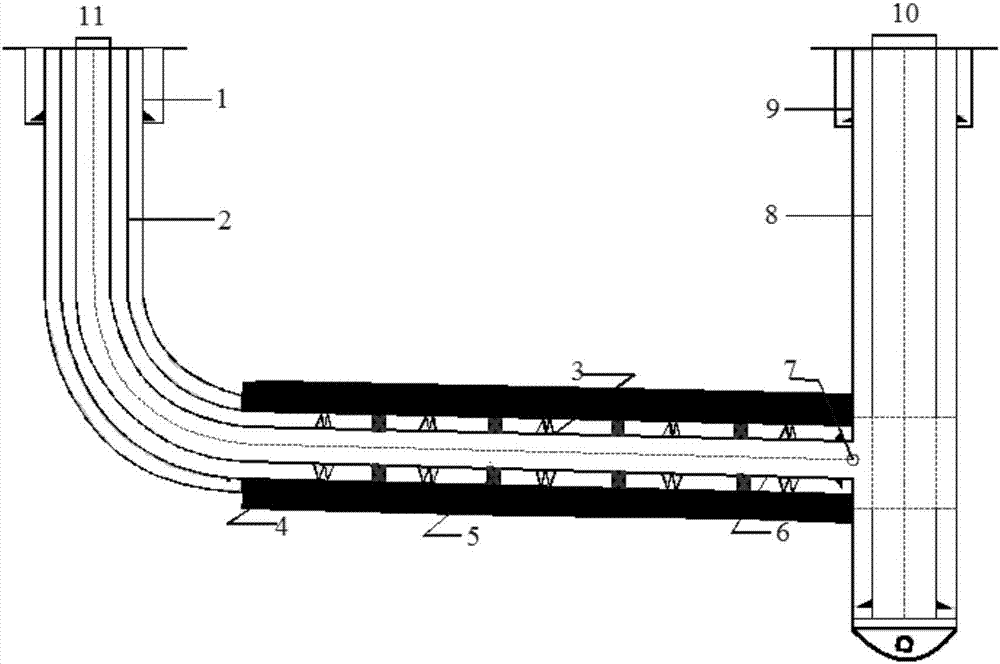

[0032] see figure 1 , shows the non-cementing casing completion coalbed methane horizontal well drainage method of the present invention, which is used for the development of coalbed methane horizontal wells in soft and low-permeability coal seams.

[0033] The non-cementing casing completion coalbed methane horizontal well drainage method comprises the following steps:

[0034] Step 1: Determine the position of the horizontal well, determine the inclination of the coal seam according to the contour line of the coal seam floor, and determine the minimum principal stress direction according to the monitoring results of hydraulic fracturing fractures, and at the same time follow the inclination of the horizontal wellbore trajectory along the coal seam and the minimum principal stress parallel to the coal seam The position of the horizontal section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com