Assembled aluminum-frame shear wall column formwork structure

An aluminum frame and shear wall technology, applied in the direction of formwork/template/work frame, formwork/formwork/work frame connector, building structure, etc., can solve the problems of poor applicability, inconvenient splicing, difficult disassembly, etc. , to achieve the effect of high assembly efficiency, improved versatility and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and example.

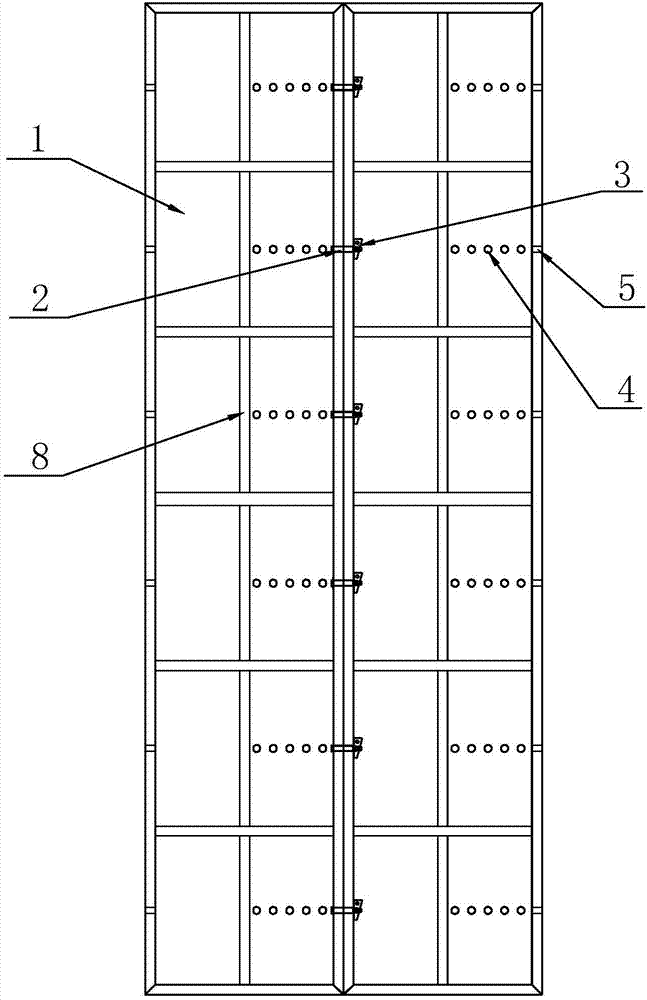

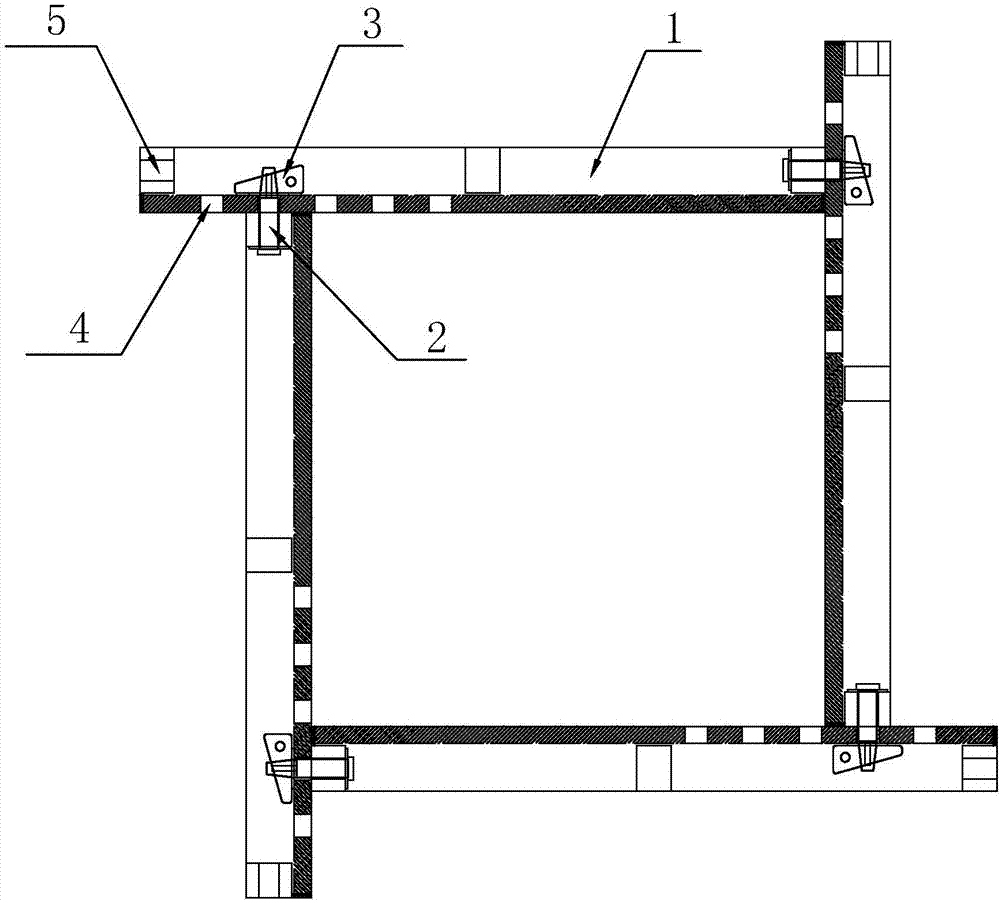

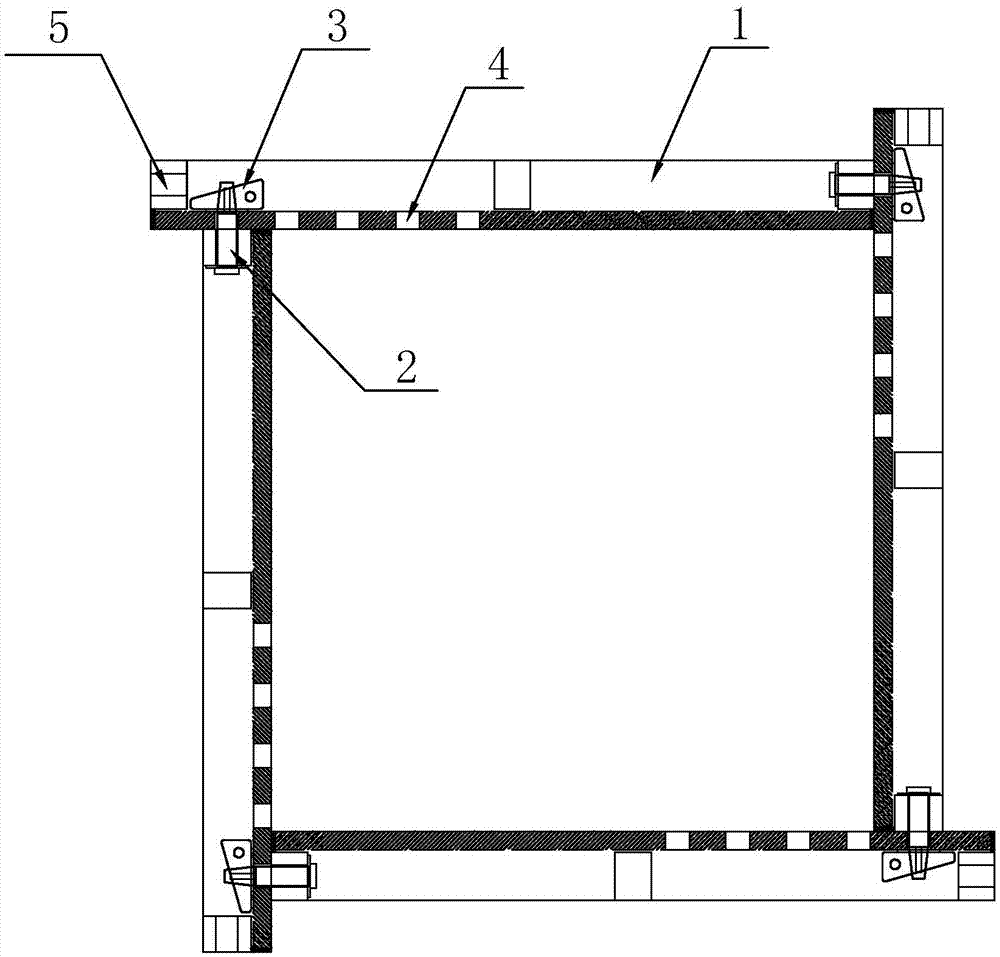

[0023] like Figure 1-5 As shown, the present invention provides an assembled aluminum frame shear wall column formwork structure, including several aluminum frame formworks 1, connectors installed on the aluminum frame formwork 1, and the aluminum frame formworks 1 are connected to each other through connectors, The frame surface of the aluminum frame template 1 is provided with a plurality of frame surface holes 4 for adjusting the piercing position of the connectors on the frame surface, and the frame edge of the aluminum frame template 1 is provided with a frame for the piercing of the connectors on the frame edge. side hole 5. The lightweight aluminum frame formwork 1 is used for splicing and assembly, which can not only be reused, but also can quickly control the pouring of shear wall columns; the aluminum frame formwork 1 is fastened and connected by con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com