Down suction type radiation tube biomass gasification producer and down suction type radiation tube biomass gasification system

A technology of gasification gas production and regenerative radiant tubes, which is applied in the direction of gasification process, gasification device feeding tool, chemical industry, etc., and can solve the problems of waste of biomass resources, environmental pollution, production capacity decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

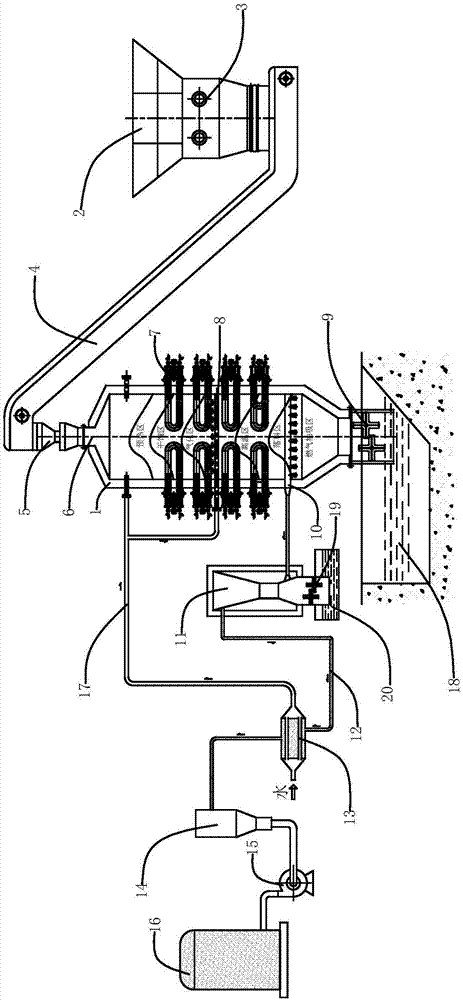

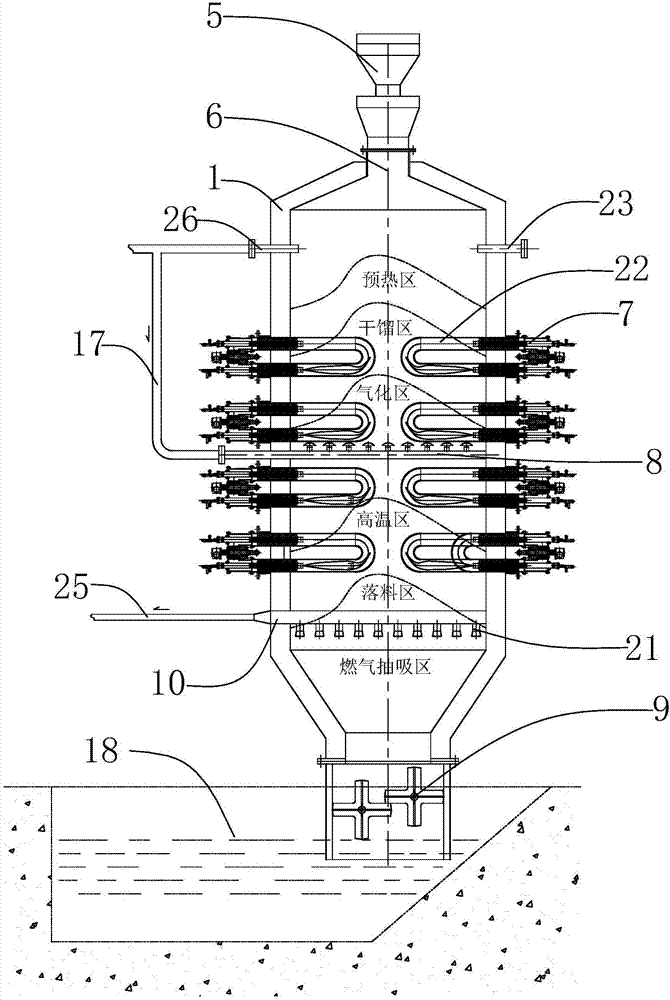

[0028] Below in conjunction with accompanying drawing, the present invention is further described:

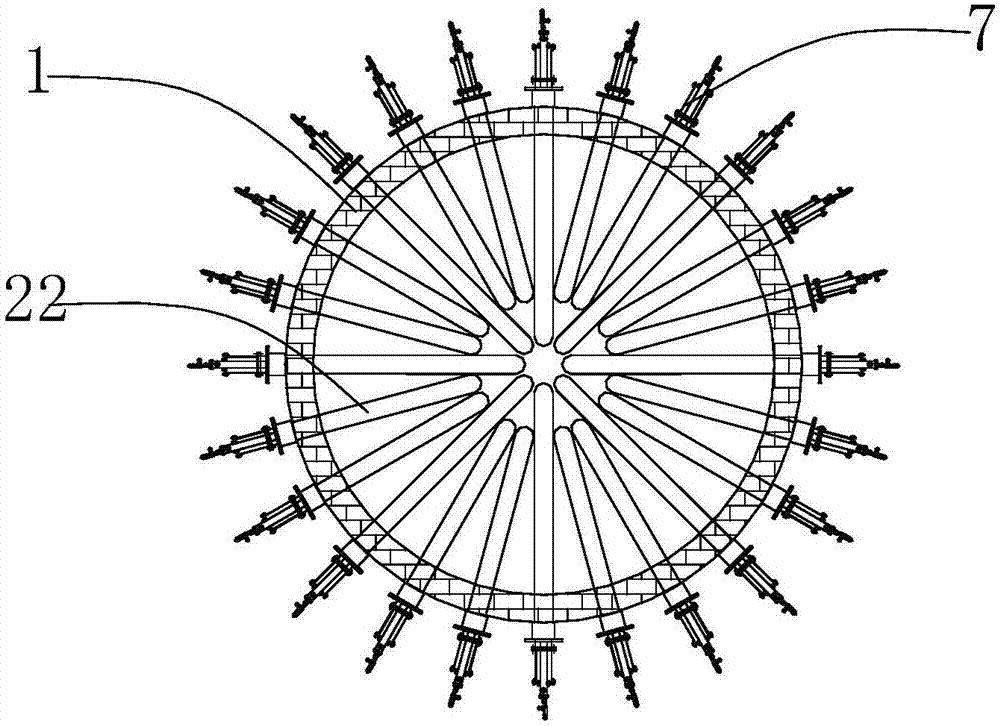

[0029] Such as figure 2 As shown, a downdraft radiant tube biomass gasification gasification furnace is characterized in that it includes a furnace body 1 for gasifying biomass raw materials. The feed port 6 of the feed port 6 is equipped with a double bell valve 5 that is convenient to open and close. The double bell valve 5 is connected to a feeder 4 for delivering biomass raw materials to the furnace body. The furnace body 1 The middle part of the furnace is evenly arranged with a regenerative radiant tube burner 7 for biomass gasification of raw materials entering the furnace body, and the regenerative radiant tube burner 7 forms a biomass gasification zone in the furnace body 1, The biomass gasification area in the furnace body 1 is provided with a steam distributor 8, and the steam distributor 8 is connected with a steam pipe 17 for providing steam to the furnace body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com