Pyrogenic distillation gasification method of biomass and device thereof

A gasification device, biomass technology, applied in the direction of biofuel, special dry distillation, petroleum industry, etc., can solve the problems of low direct utilization rate, excessive dust, affecting the promotion and application development of biomass gas technology, etc., to achieve The effect of continuous charcoal production and less dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

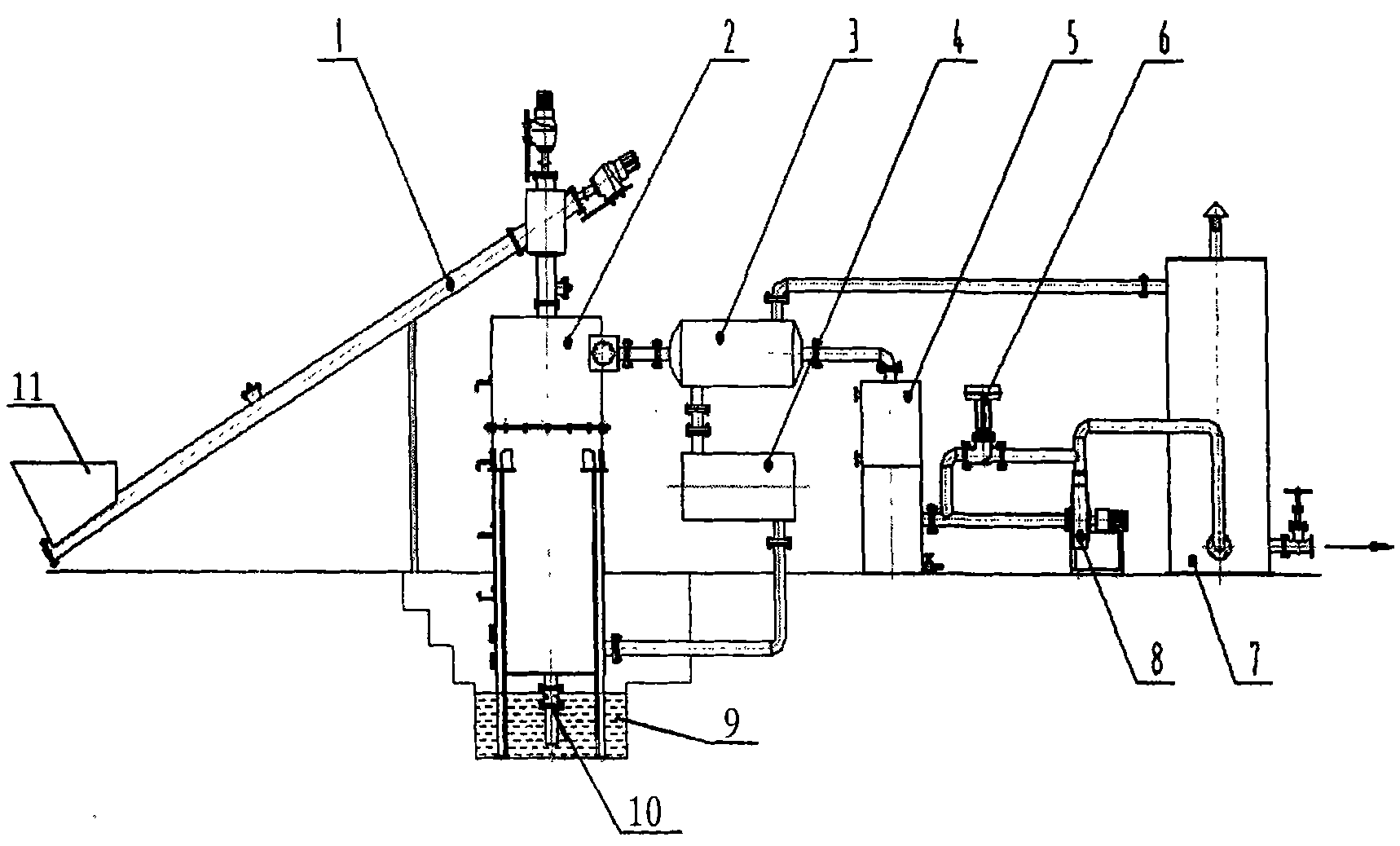

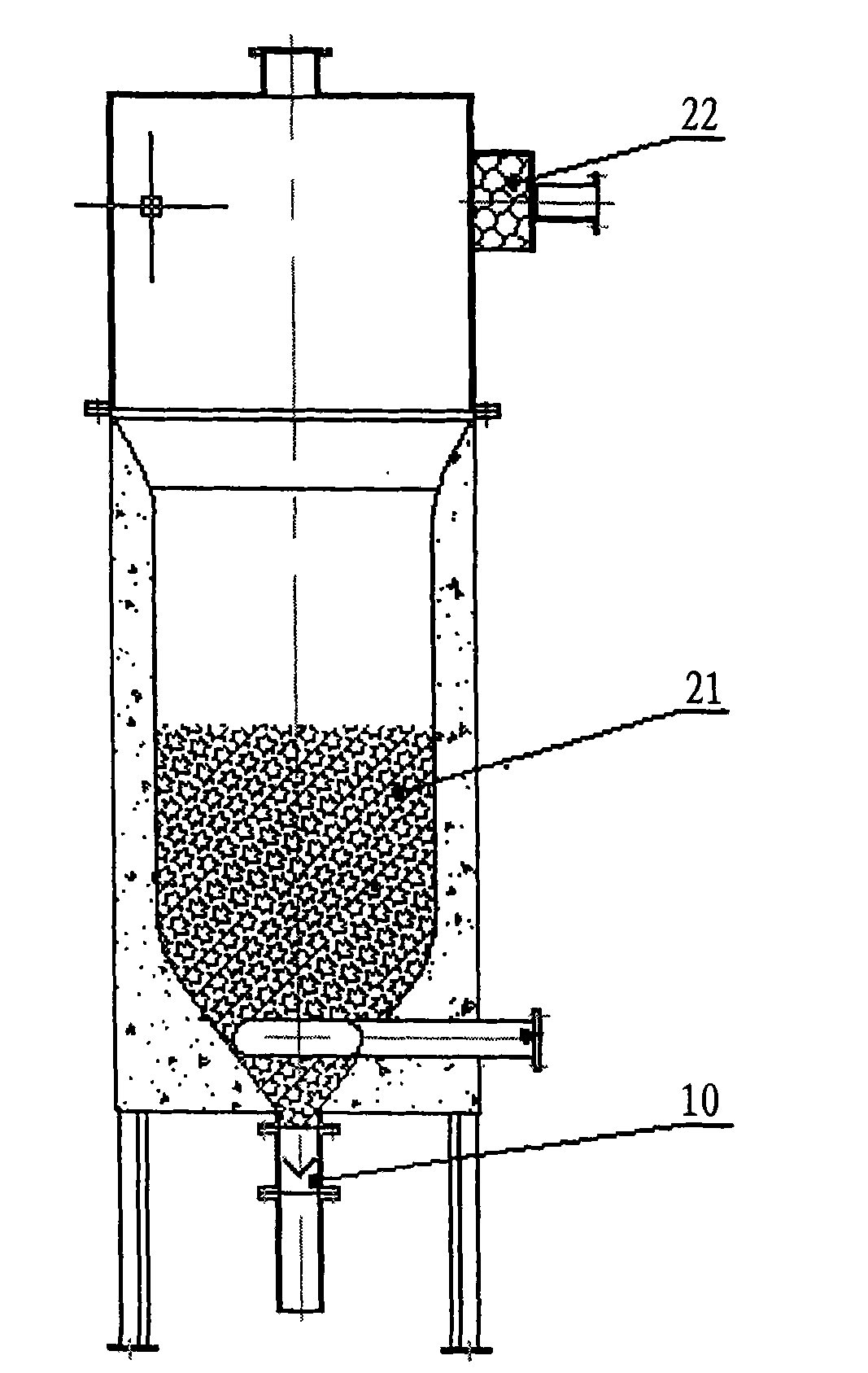

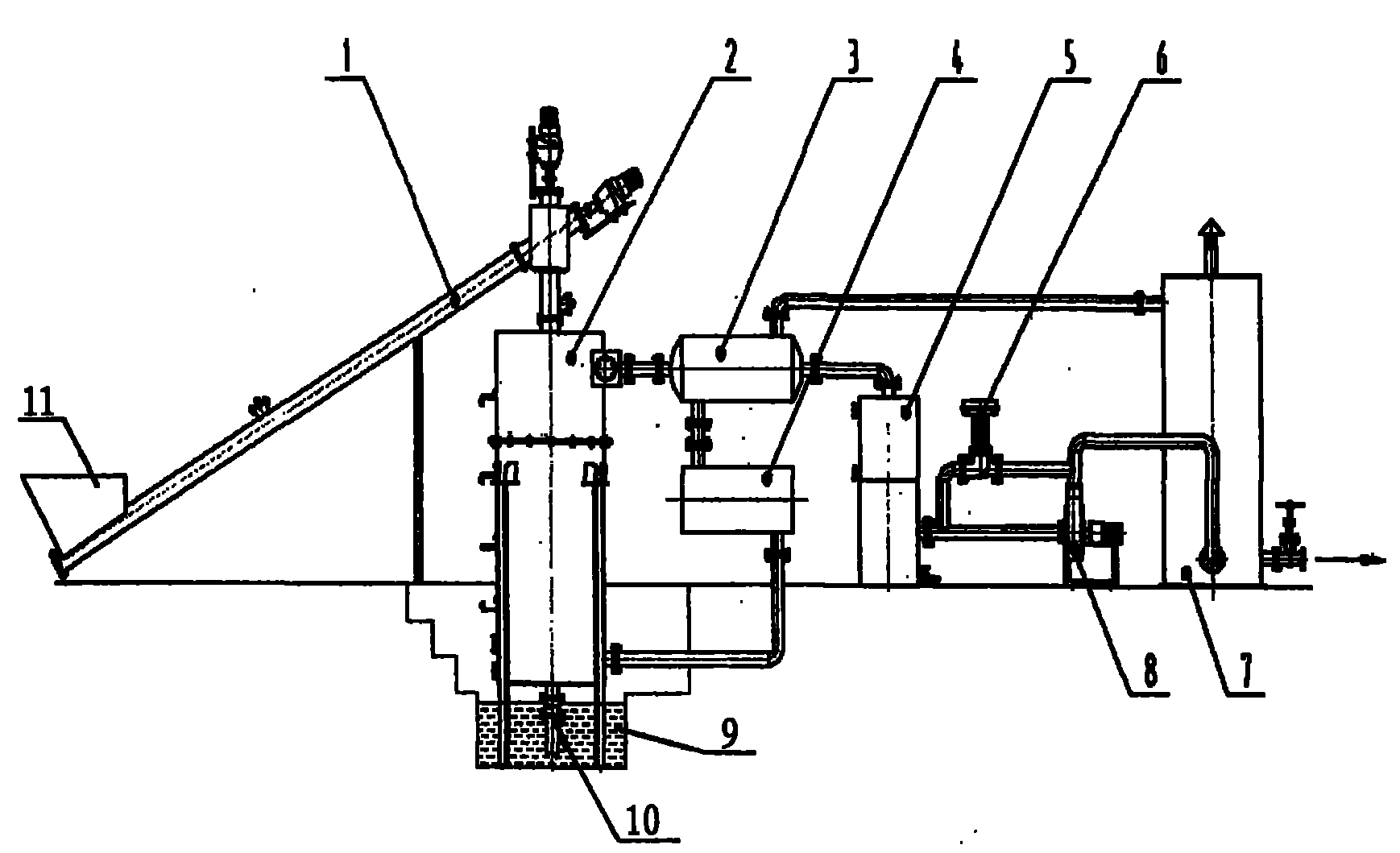

[0015] A biomass dry distillation gasification method, including material feeding, heating, and heat exchanging processes. It also includes dry distillation and cryogenic process, which is carried out on the biomass dry distillation gasification device. The biomass dry distillation gasification device includes a feeder and a hopper, a dry distillation gasifier, and a high-temperature heat exchanger. , a heater, a cryocooler, an automatic pressure adjustment valve, a gas cabinet, and a fan. The retort gasifier is installed semi-underground, with a water-sealed pool at its lower part, and a feeder is installed on the top of the retort gasifier. The upper part of the chemical furnace, the high-temperature heat exchanger, the deep cooler, the automatic pressure adjustment valve, the fan and the gas cabinet are connected in sequence through pipelines, the high-temperature heat exchanger is connected with the top of the heater through pipelines, and the lower part of the retort gasif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com