Gas well auxiliary liquid carrying system

A technology for gas wells and gas-liquid separation devices, which can be used in wellbore/well components, production fluids, earth-moving drilling, etc., and can solve the problems of limited economic benefits and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

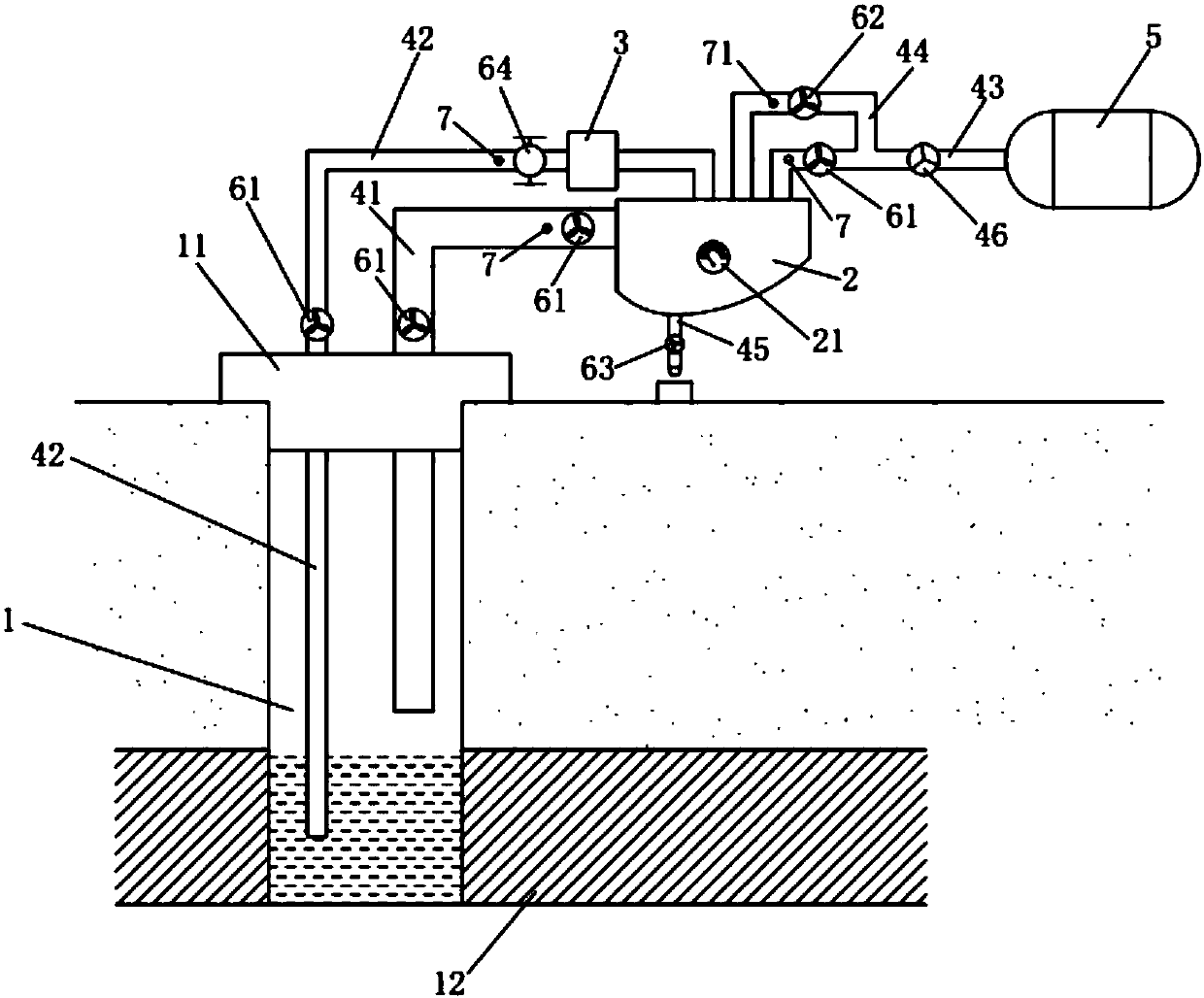

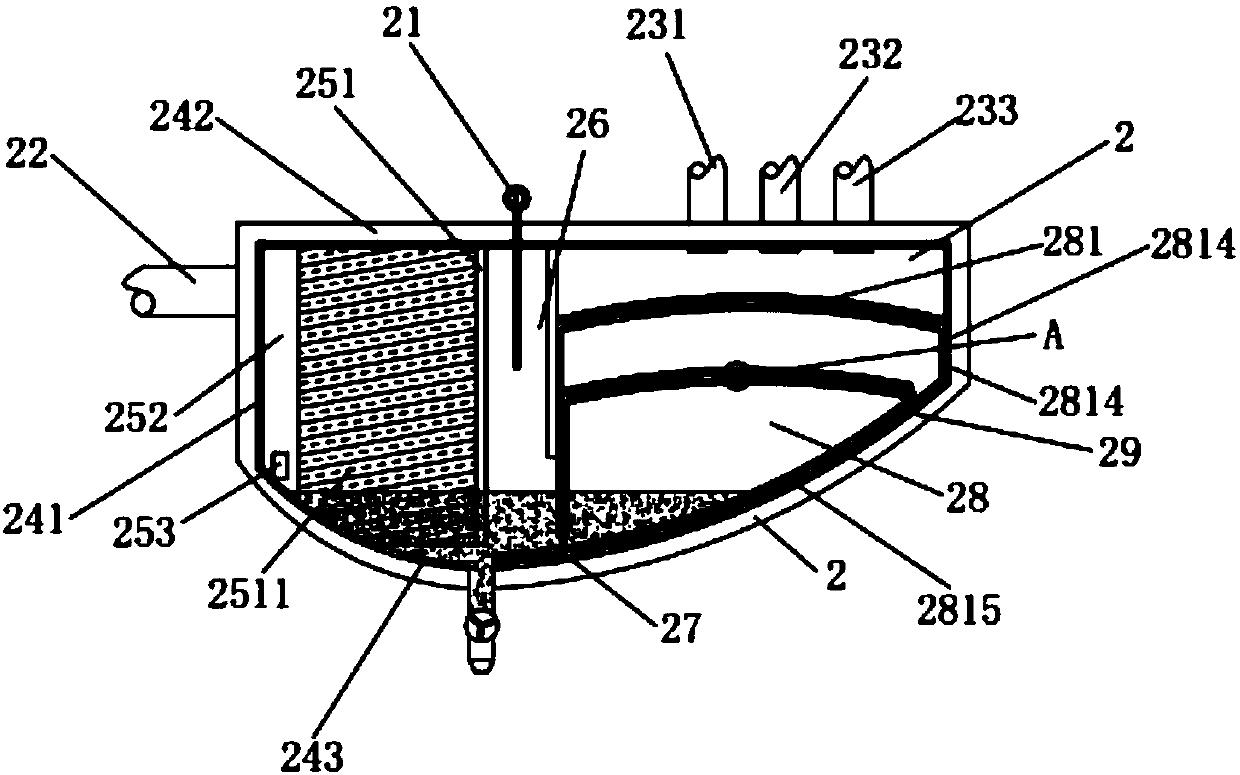

[0022] Please refer to figure 1 , the embodiment of the present invention provides a gas well auxiliary liquid carrying system, which is used to collect the gas in the gas well 1, and control the amount of liquid accumulation in the gas well 1, so as to prevent the gas well from reducing production or even shutting down due to the increase of liquid accumulation, mainly including Gas well 1 and gas-liquid separation device 2.

[0023] The gas well 1 is a gas well, and the middle area or the lower end area in the gas well 1 has a gas-liquid mixture, and the gas-liquid mixture flows into the wellbore from the oil and gas reservoir 12 due to the pressure difference. Tree 11, one is to facilitate the extension of oil pipe 41 and return pipe 42 into the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com