A preparation method of hybrid functionalized carbon nanotubes and nanoparticles synergistically modified epoxy resin adhesive

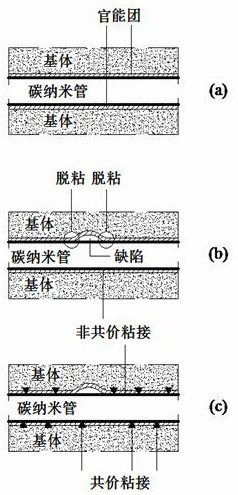

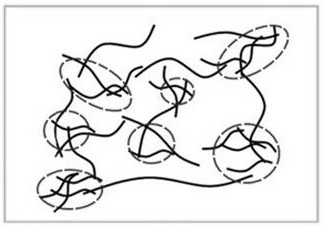

A carbon nanotube and epoxy resin technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of uneven distribution of non-covalent functional groups, carbon nanotube slippage, interface debonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Preparation of modified epoxy resin adhesive: Disperse a certain amount of hybrid functionalized carbon nanotubes and functionalized nano-silica in toluene solution, ultrasonically oscillate for 2 hours, then add a certain amount of epoxy resin, and continue ultrasonically oscillating for 2 hours. Afterwards, the above mixed solution was placed in a vacuum drying oven, and vacuumized for 1-3 hours to evaporate the toluene solvent. Raise the temperature to 50°C, add a certain amount of curing agent, stir evenly, and then use it for casting tensile test specimens or bonding tensile shear test specimens.

[0037] The tensile performance test of the adhesive material is carried out in accordance with the specification GB / T 1014-1992: the sample size is Type I, the adhesive is evenly stirred and cast into a mold, and then solidified step by step by vacuuming in a vacuum drying oven to remove air bubbles. The prepared specimens were cooled naturally to room temperature and de...

Embodiment 1

[0040] Preparation of hybrid functionalized carbon nanotubes and nano-silica modified epoxy resin adhesives, the number of carboxyl and hydroxyl groups introduced on the surface of carbon nanotubes does not exceed 1% of the number of atoms on the surface of carbon nanotubes, and the modified epoxy resin adhesive contains 0.01wt % MWCNTs-Epon828-PPA and 0.01wt% and nano-silica. Two kinds of samples were prepared, and tensile test and tensile shear test were carried out respectively. The measured tensile strength was 95.7MPa, elastic modulus was 0.86GPa, and tensile shear strength was 28.8MPa.

Embodiment 2

[0042] Preparation of hybrid functionalized carbon nanotubes and nano-silica modified epoxy resin adhesives, the number of carboxyl and hydroxyl groups introduced on the surface of carbon nanotubes does not exceed 1% of the number of atoms on the surface of carbon nanotubes, and the modified epoxy resin adhesive contains 0.05wt % MWCNTs-Epon828-PPA and 0.05wt% nano-silica. Two kinds of samples were prepared, and tensile test and tensile shear test were carried out respectively, and the measured tensile strength was 103.4MPa, elastic modulus was 0.92GPa, and tensile shear strength was 29.6MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com