Hyaluronic acid derivative self-crosslinking hydrogel with oxidized hydroxyethyl cellulose as crosslinking agent and preparation method thereof

A technology of hydroxyethyl cellulose and oxidized hydroxyethyl, which is applied in the field of polymer chemistry, can solve the problems of limiting the practical application of hyaluronic acid, cytotoxicity, and high pH sensitivity, and achieve sustainable development and high water swelling Good performance and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

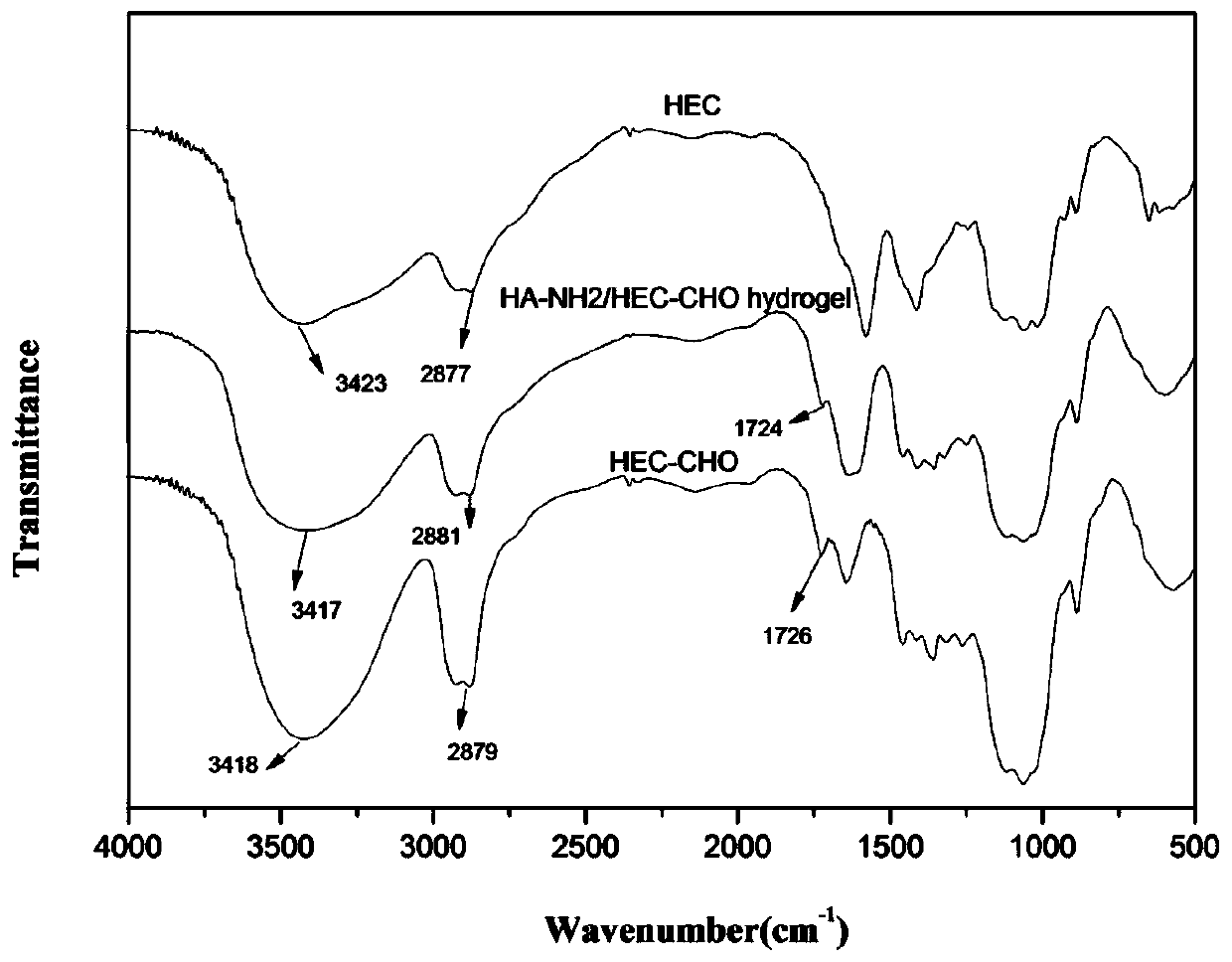

[0037] Preparation of oxidized hydroxyethyl cellulose: 3g of hydroxyethyl cellulose was dissolved in 300mL of distilled water: ethanol = 1:1 (v / v) mixed solvent, 2.7g of sodium periodate was dissolved in 50ml of distilled water, in 4 The reaction was kept at ℃ for 24 hours in the dark, and 5 mL of ethylene glycol was added and stirred for 60 minutes to terminate the reaction, and then purified to obtain oxyethyl cellulose. After measurement, the oxidation degree of oxidized hydroxyethyl cellulose is 68.5%, and the relative molecular weight is 113,000, which is basically unchanged compared with hydroxyethyl cellulose, and is much higher than the 39,000 of conventional oxidation system. The infrared spectrum of the oxidized hydroxyethyl cellulose by infrared characterization is shown in figure 1 Compared with hydroxyethyl cellulose, oxidized hydroxyethyl cellulose has a new absorption peak at the wavelength of 1734.8, which is attributed to the stretching vibration absorption peak...

Embodiment 2

[0039] Preparation of oxidized hydroxyethyl cellulose: 3g of hydroxyethyl cellulose was dissolved in 300mL of distilled water: ethanol = 1:1 (v / v) mixed solvent, 1.8g of sodium periodate was dissolved in 50ml of distilled water, in 4 The reaction was kept at ℃ for 24 hours in the dark, and 5 mL of ethylene glycol was added and stirred for 60 minutes to terminate the reaction, and then purified to obtain oxidized hydroxyethyl cellulose. After measurement, the oxidation degree of oxidized hydroxyethyl cellulose is 48.7%, and the relative molecular mass is 134,000, which is basically unchanged compared with hydroxyethyl cellulose, and is much higher than the 70,000 of conventional oxidation system.

Embodiment 3

[0041] Preparation of oxidized hydroxyethyl cellulose: 3g of hydroxyethyl cellulose was dissolved in 300mL of distilled water: ethanol = 1:1 (v / v) mixed solvent, 0.9g of sodium periodate was dissolved in 50ml of distilled water, in 4 The reaction was kept at ℃ for 24 hours in the dark, and 5 mL of ethylene glycol was added and stirred for 60 minutes to terminate the reaction, and then purified to obtain oxyethyl cellulose. After measurement, the oxidation degree of oxidized hydroxyethyl cellulose is 30%, and the relative molecular mass is 157,000, which is basically unchanged compared with hydroxyethyl cellulose, and is much higher than the 82,000 of the conventional oxidation system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com