Separation method of pyridine derivatives in prazole production

A separation method and derivative technology, applied in the direction of organic chemistry, can solve the problems of high residue, high internal temperature, high risk, etc., and achieve the effects of mild distillation process conditions, lower operating temperature, and improved volatile characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

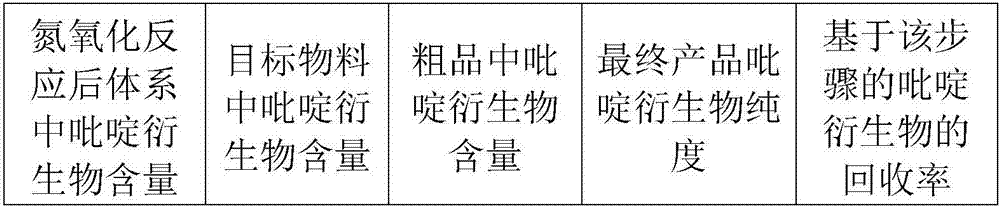

[0026] The specific steps of separation and recovery of pyridine derivatives after the nitrogen oxidation reaction in the prazole production step are as follows:

[0027] 1) After the nitrogen oxidation reaction in the prazole production step, add 3 times of volume of pure water in the system, adjust the pH to be 2, add 2 times of volume of chlorinated hydrocarbon organic solvent, select methylene chloride here, carry out Extraction, the separation of the organic layer and the water layer after the extraction is completed, the organic layer continues to the next step of prazole production reaction, and the water layer is set aside;

[0028] 2) adjust the pH of the water layer to 9, add 2 times the volume of an aromatic hydrocarbon organic solvent, select benzene here, and perform extraction, and the obtained organic layer is fractionated at 80-82° C. to recover the organic solvent to obtain a crude pyridine derivative;

[0029] 3) Refining of pyridine derivatives: the obtained...

Embodiment 2

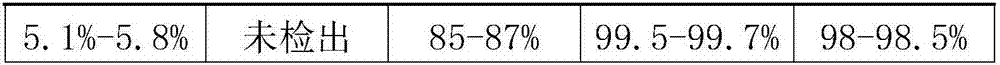

[0036] The specific steps of separation and recovery of pyridine derivatives after the nitration reaction in the prazole production step are as follows:

[0037] 1) after the nitration reaction in the prazole production step, add 3.1 times of pure water in volume in the system, adjust pH to be 3, add the chlorinated hydrocarbon organic solvent of 5 times of volume, select ethylene dichloride here, carry out Extraction, the separation of the organic layer and the water layer after the extraction is completed, the organic layer continues to the next step of prazole production reaction, and the water layer is set aside;

[0038] 2) adjust the pH of the water layer to be 12, add 5 times the volume of chlorinated hydrocarbon organic solvents, choose chloroform as the organic solvent for extraction, and extract the organic layer under normal pressure at 61-63 ° C to recover the organic solvent, Obtain the crude product of pyridine derivative;

[0039] 3) Refining of pyridine deriva...

Embodiment 3

[0045] The specific steps of separation and recovery of pyridine derivatives after the chlorination reaction in the prazole production step are as follows:

[0046] 1) After the chlorination reaction in the production step of prazole, add 3.2 times of volume of pure water in the system, adjust the pH to be 5, add 10 times of volume of ester organic solvent, select ethyl acetate for extraction here, After the extraction is completed, the organic layer and the water layer are separated, the organic layer continues to the next step of prazole production reaction, and the water layer is set aside;

[0047] 2) Adjust the pH of the water layer to 14, add 10 times the volume of an ester organic solvent, here choose ethyl acetate, and carry out extraction, the obtained organic layer is fractionated at 77-79°C to recover the organic solvent, and the crude pyridine derivative is obtained ;

[0048]3) Refining of pyridine derivatives: the obtained crude pyridine derivatives are put into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com