An injection molding device for extrusion cutting

An injection mold, No. 1 technology, applied in the field of injection molding, can solve the problems of long molding time, dust on the surface, bubble generation, etc., and achieve the effect of convenient injection molding, easy cutting and recycling, and good extrusion molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

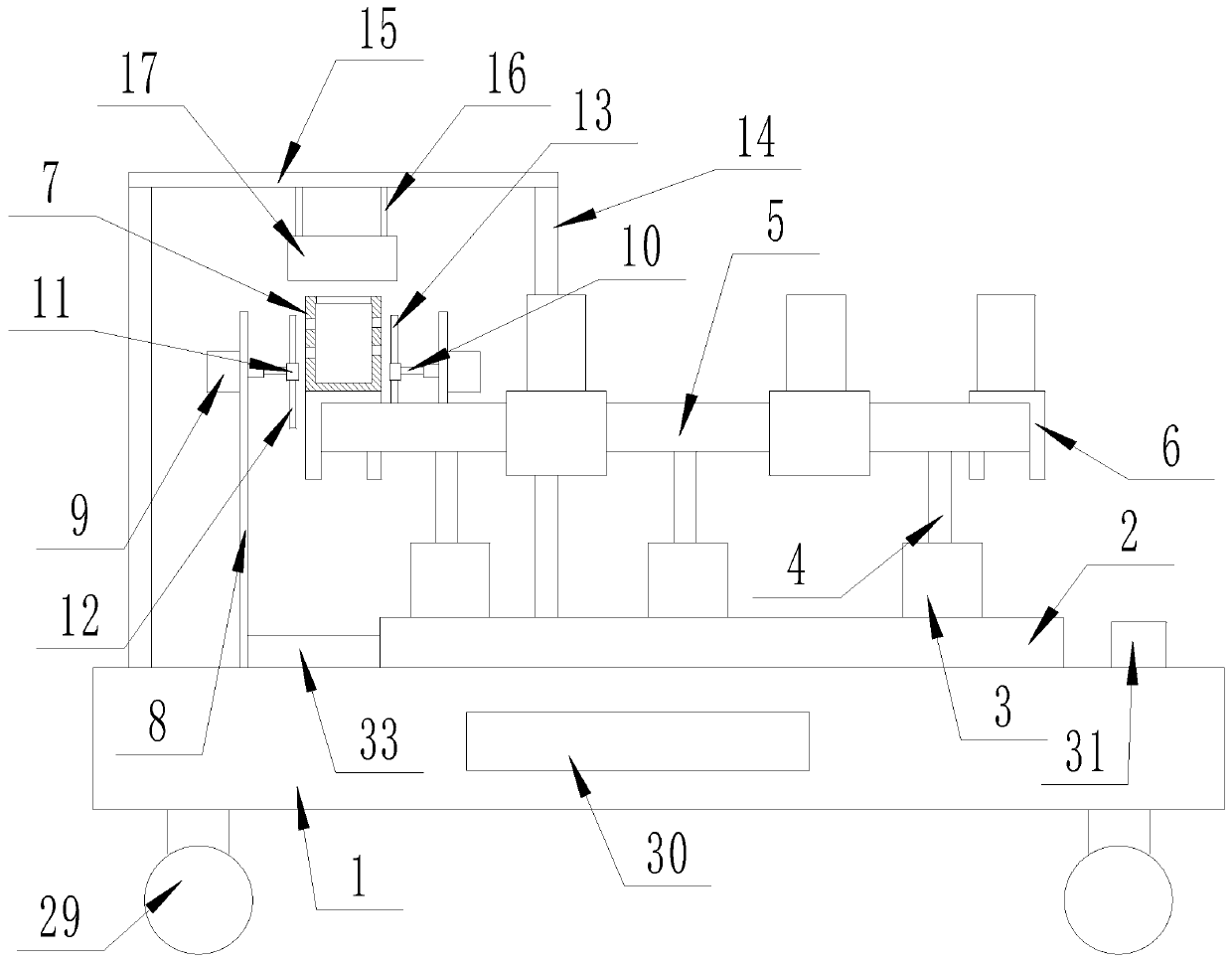

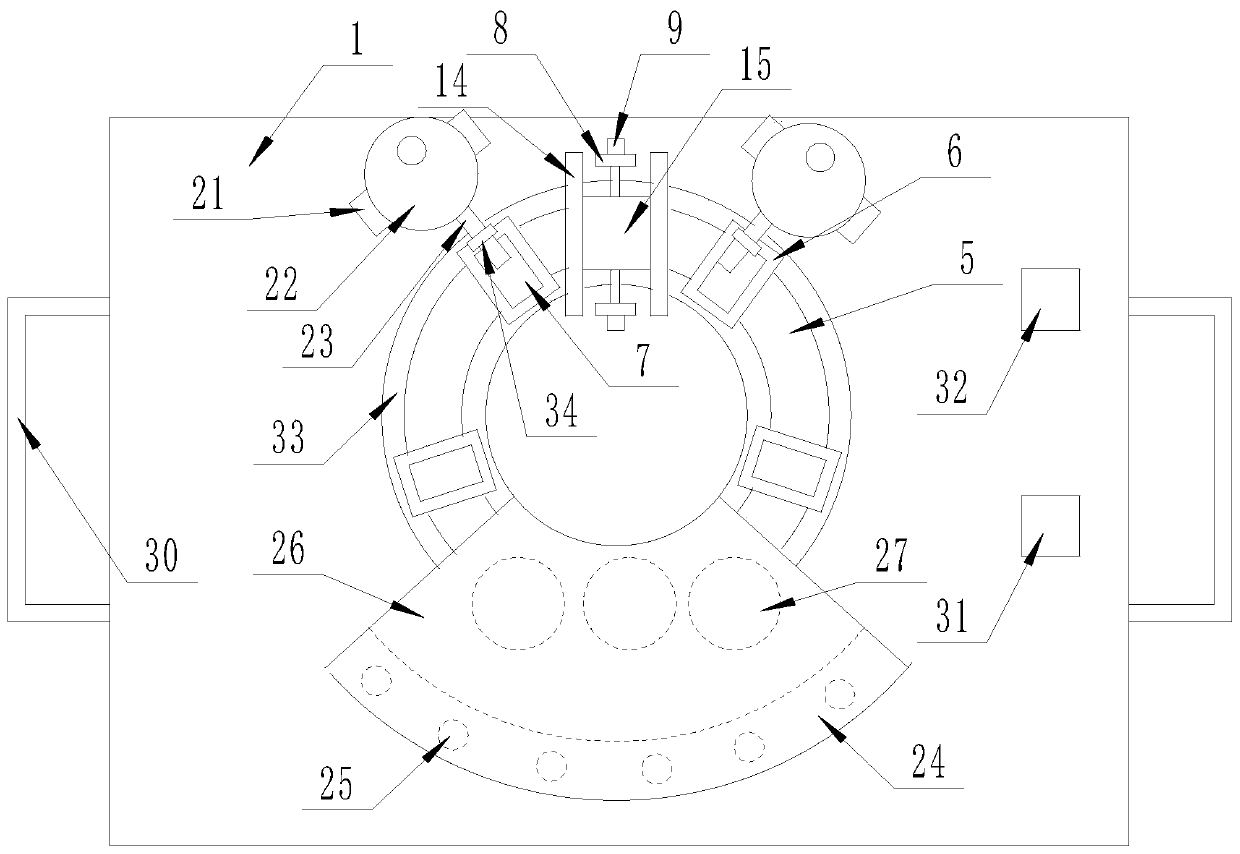

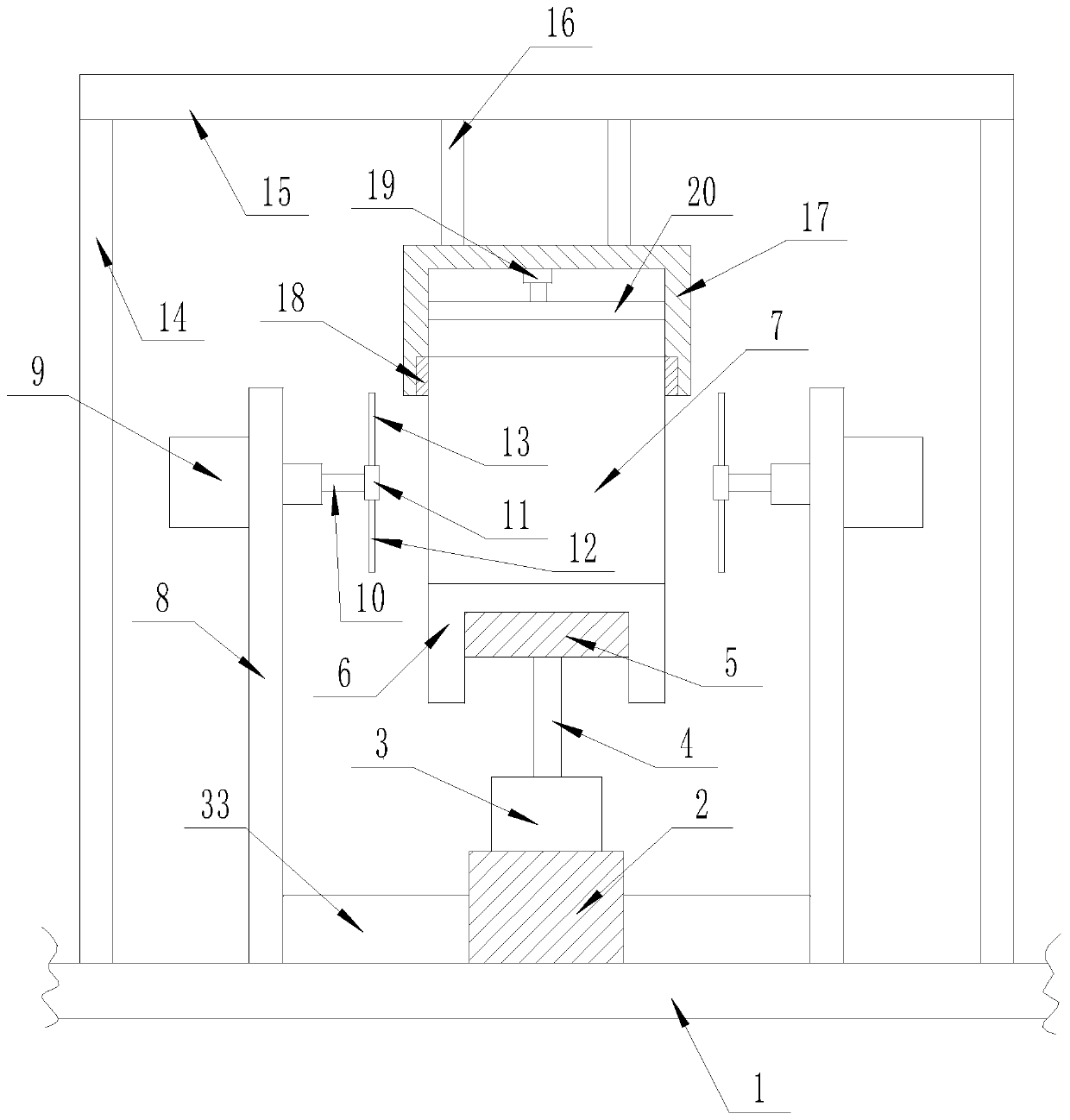

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, an extrusion cutting injection molding device includes a bar-shaped bearing base 1, an extrusion cutting injection molding mechanism is arranged at the center of the upper surface of the strip-shaped bearing base 1, and the extrusion cutting injection molding mechanism is fixedly connected The ring slide rail 2 at the center of the upper surface of the bar-shaped bearing base 1, a plurality of electric control trolleys 3 arranged on the circular slide rail 2, and a support pole 4 fixedly connected to the upper surface of each electric control trolley 3 , fixedly connected to the ring bearing plate 5 on the upper surface of a plurality of support poles 4, a plurality of N-shaped fixed bases 6 arranged on the upper surface of the ring bearing plate 5, and arranged on the upper surface of each N-shaped fixed base 6 Injection mold 7, two sets of extrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com