Double-layer shield chip preventing device

A shield and anti-chip technology, applied in the field of CNC machine tools, can solve the problems of chips flying out at high speed, shortening the life of the machine tool, affecting the accuracy of the machine tool, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

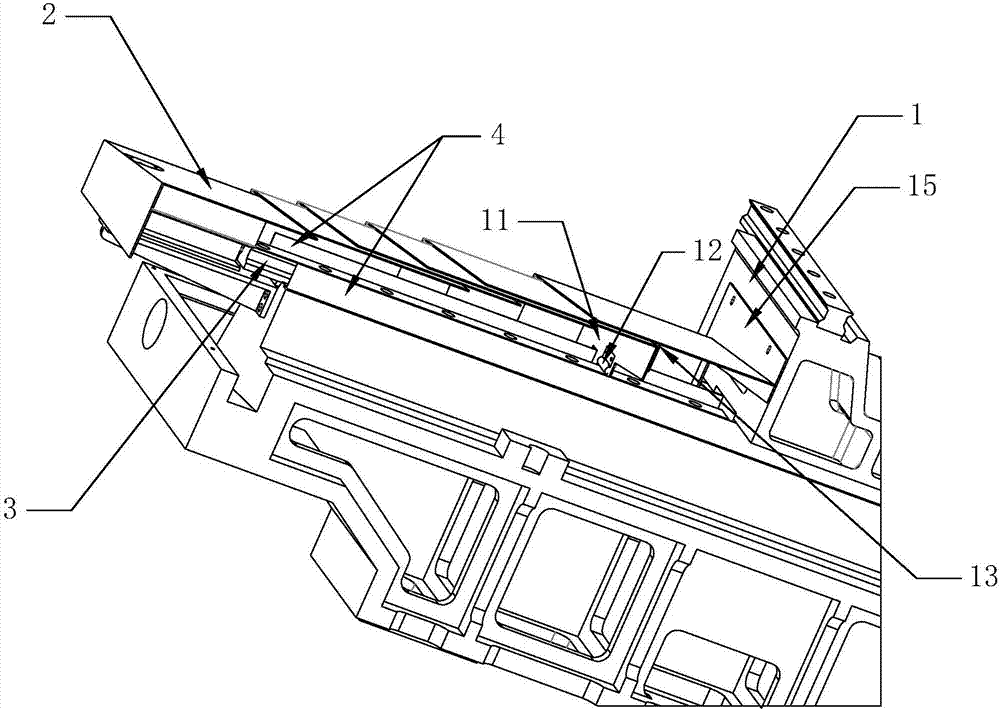

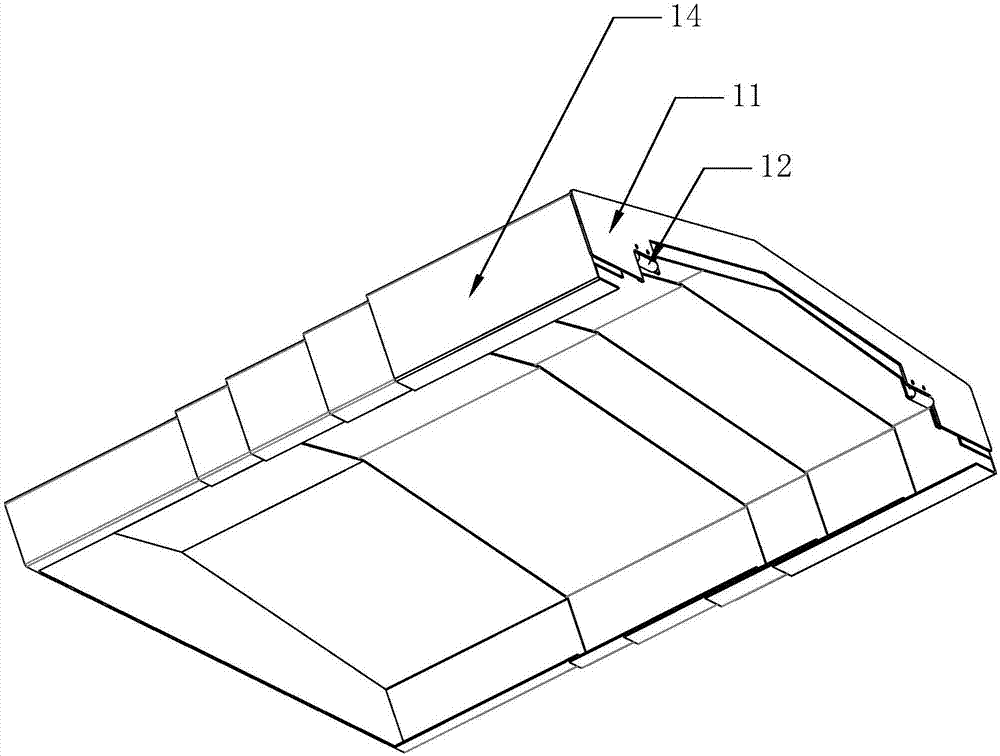

[0016] refer to Figure 1 to Figure 2 , a kind of double-layer shield anti-chip device of the present invention, comprises machine platform 1, line rail 3, the outer layer shield 2 that is arranged on the top of line rail 3 and the protective plate 4 that is arranged on the both sides of line rail 3, and described outer layer The protective cover 2 is detachably connected to the protective plate 4, the outer protective cover 2 includes several protective covers 14, and the protective covers 14 are stacked one above the other, and the outer protective cover 2 is close to the machine platform 1 The lower part of the protective cover 14 on one side is provided with a first baffle 11 , and the lower part of the first baffle 11 is provided with a roller 12 , and the outer protective cover 2 is connected with a driving device for controlling the movement of the protective cover 14 .

[0017] Preferably, the lower part of the outer shield 2 is provided with a slot for accommodating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com