Electromagnetic pulse based air-assist thermal forming device and forming method for light-alloy pipe fittings

An electromagnetic pulse and forming device technology, applied in the field of metal material processing and forming, can solve the problems of increasing the forming process and production cost, and achieve the effect of flexible use, high utilization rate, high efficiency and precision forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

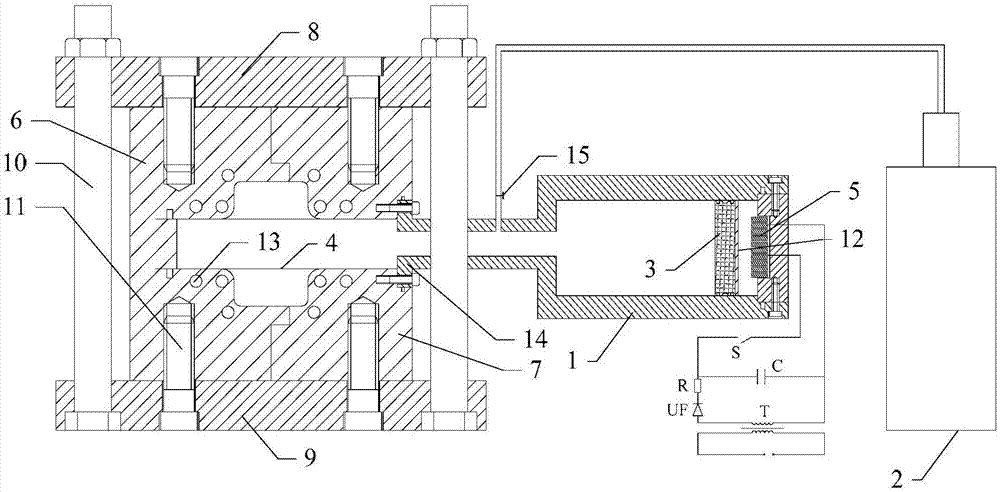

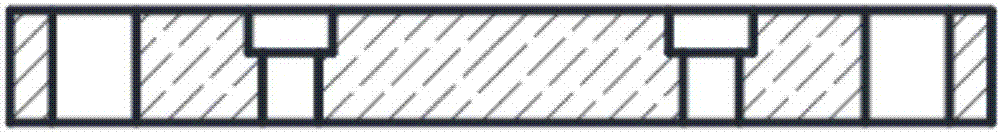

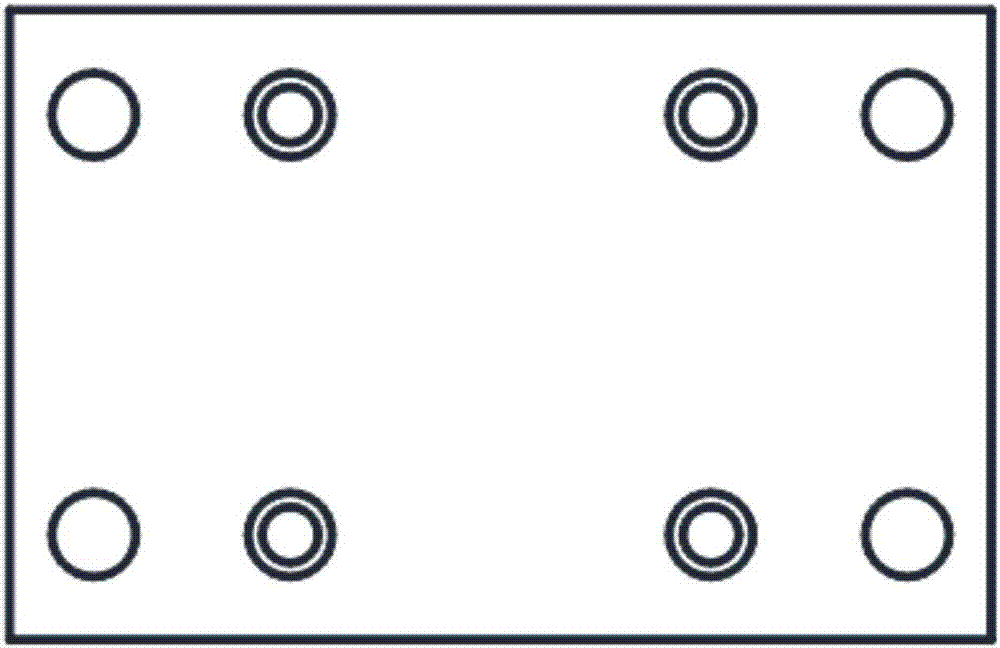

[0054] Example: Combine below Figure 1 to Figure 11 This embodiment will be described in detail.

[0055] The electromagnetic pulse-based inflatable thermoforming device for light alloy pipes in this embodiment includes a combined mold unit, a high-pressure gas storage unit 1, a high-pressure gas generation unit 2, an electromagnetic pulse generation unit, a compression unit 3, and a temperature-controlled heating unit;

[0056] The pipe 4 to be formed is fixed in the combined mold unit, and the insides of the pipe 4, the high-pressure gas storage unit 1 and the high-pressure gas generation unit 2 are connected in pairs;

[0057] The electromagnetic pulse generating unit includes a high-voltage pulse generating sub-unit and a plate coil 5, which form an electrical circuit;

[0058] The compression unit 3 is used to squeeze the gas in the high-pressure gas storage unit 1 into the pipe 4 under the action of the electromagnetic force generated by the plate coil 5; the temperature contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com