Crusher for cast iron wallboard

A crusher and wallboard technology, applied in grain processing, etc., can solve problems such as complicated welding of crusher wallboards, difficulty in installing and replacing block materials, etc., and achieve the requirements of improving mechanical properties, realizing humanization, and high welding precision requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

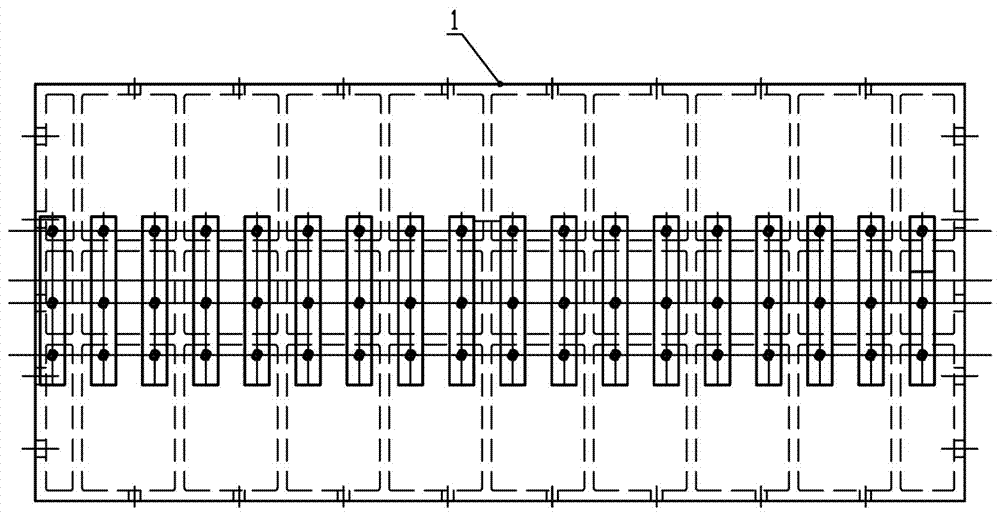

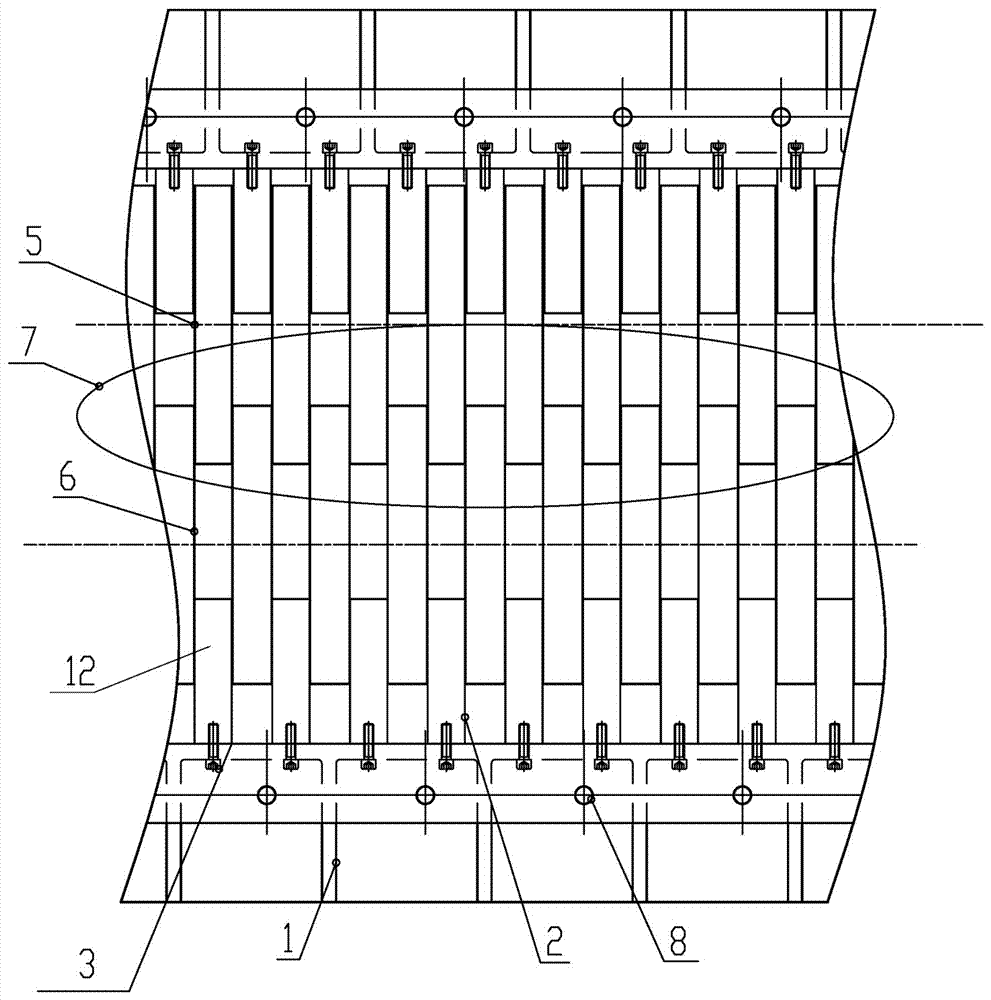

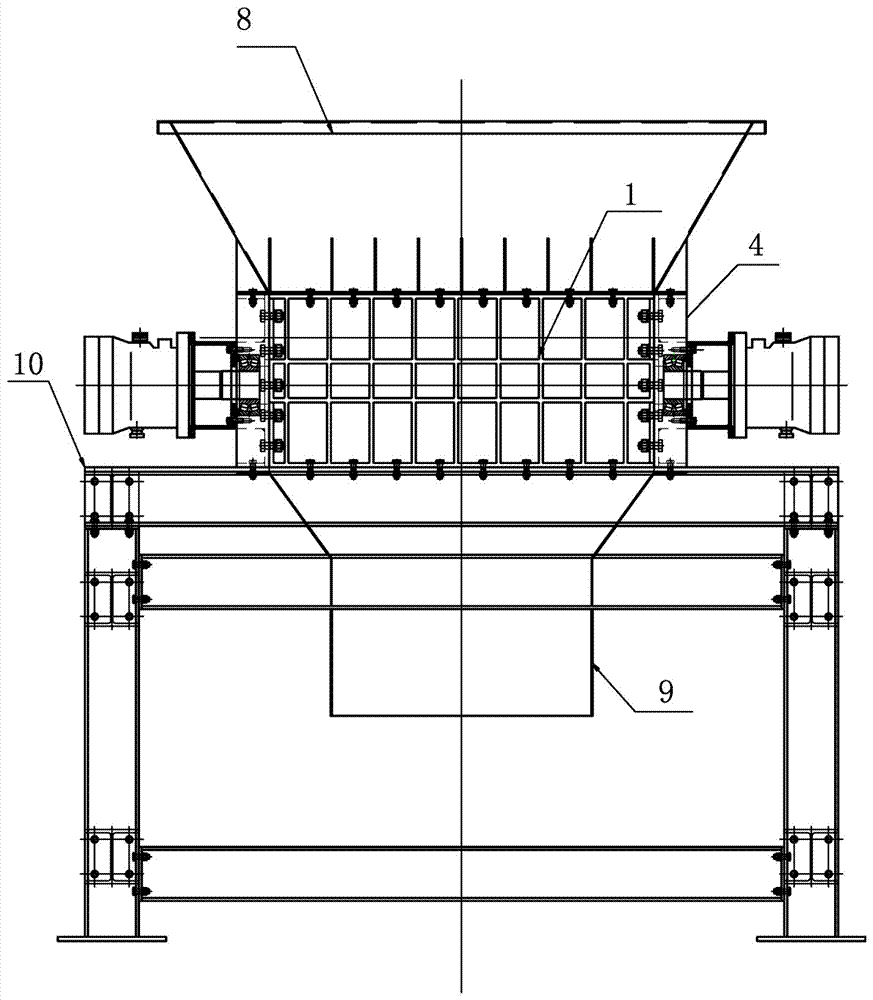

[0023] Such as figure 1 , 2 , 3, and 4, the present invention provides a crusher for cast iron wallboards, including a crushing roller A, a crushing roller B, a wallboard 1, a sideboard 4, an upper hopper 8, a lower hopper 9, a platform 10, and a wallboard 1 The whole one-time casting molding process is adopted to directly cast the bolt holes connected with the retaining block 2, the upper hopper, the platform 10 and the side plate 4, and the directly casted wall panels are provided with multiple rows of square ribs 11 evenly distributed.

[0024] The wallboard 1 is divided into left and right wallboards, and the left and right wallboards are movably connected with the upper hopper 8, the platform 10 and the side panels respectively, and can be connected with corresponding threaded hole bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com