Preparation method of a nitrogen-containing carbon quantum dot/graphite phase carbon nitride composite photocatalyst

A technology of graphite phase carbon nitride and quantum dots, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and hydrogen production, to achieve good photocatalytic effects, overcome extraction and separation difficulties, and improve photocatalytic hydrogen production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

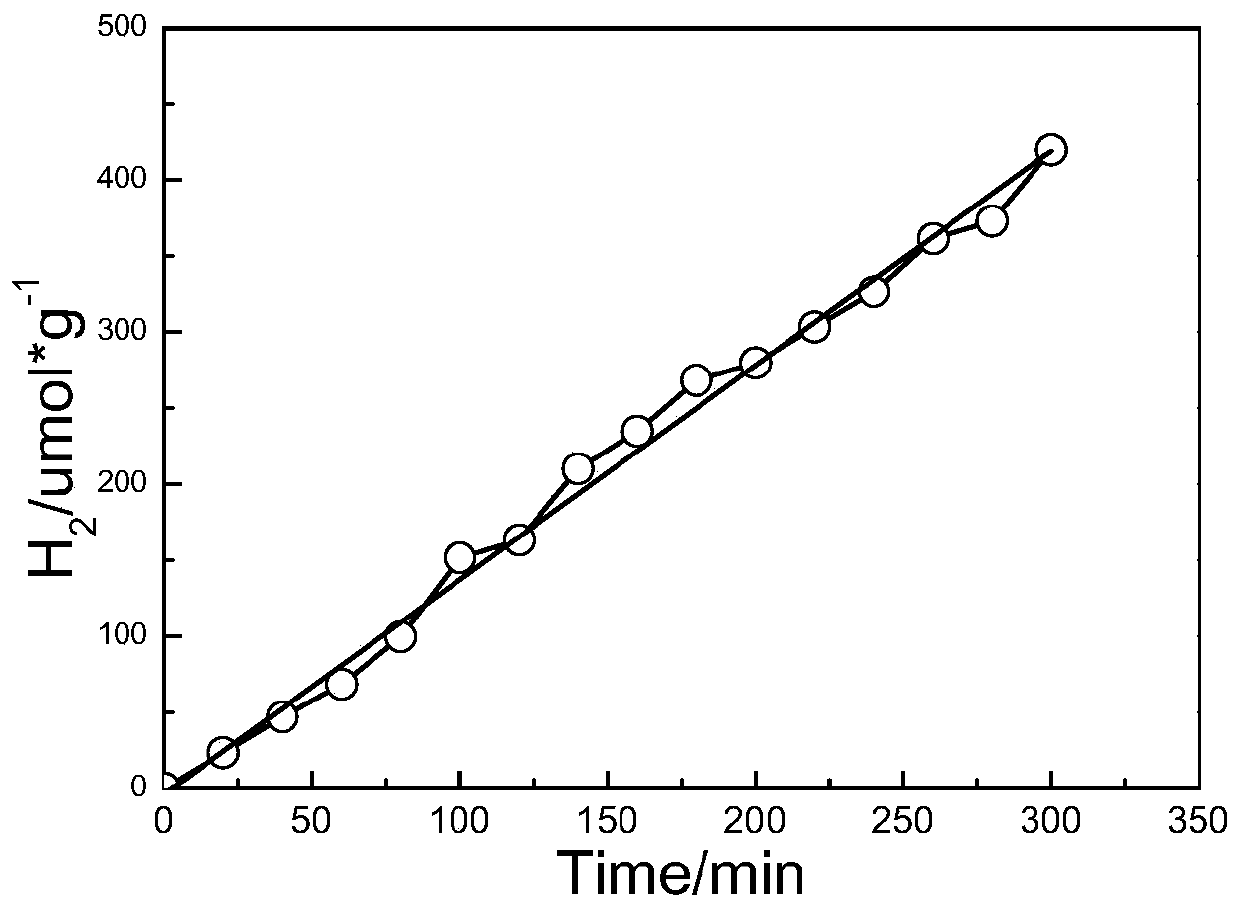

Examples

Embodiment 1

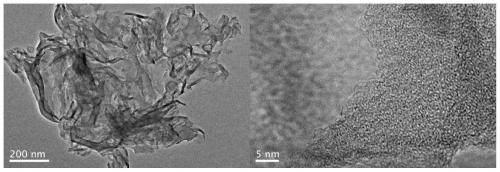

[0027] Preparation of composite photocatalyst with 5wt.% nitrogen-containing carbon quantum dots

[0028] (1) Preparation of nitrogen-containing carbon quantum dots

[0029] Under the protection of nitrogen atmosphere, according to the mass ratio of 5:1, glucose and glycine were evenly mixed and then placed in a sealed ball mill tank of a ball mill, mechanically ball milled at room temperature (25°C, the same below) for 4 hours, the speed was 580rpm, and the ball-to-material ratio was 20:1, the diameter of the agate ball used is 5mm;

[0030] After the ball milling is finished, the product is fully washed, high-speed centrifuged and dialyzed, the centrifugal speed is 10000rpm, and the dialyzed time is 3h, and then the obtained nitrogen-containing carbon quantum dot solution is rotated to evaporate the solvent to obtain nitrogen-containing carbon quantum dots;

[0031] The above-mentioned nitrogen-containing carbon quantum dots were refluxed in an excess of concentrated nitric...

Embodiment 2

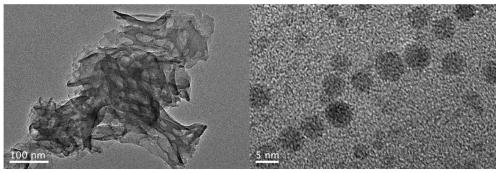

[0036] Preparation of composite photocatalyst with 50wt.% mass percentage of nitrogen-containing carbon quantum dots

[0037] (1) Preparation of nitrogen-containing carbon quantum dots

[0038] Under the protection of nitrogen atmosphere, according to the mass ratio of 5:1, glucose and glycine were evenly mixed and then placed in a sealed ball mill jar of a ball mill, mechanically ball milled at room temperature (25°C, the same below) for 8 hours, the speed was 1000rpm, and the ball-to-material ratio was 60:1, the diameter of the agate ball used is 20mm;

[0039] After the ball milling is finished, the product is fully washed, high-speed centrifuged and dialyzed, the centrifugal speed is 30000rpm, and the dialyzed time is 20h, and then the obtained nitrogen-containing carbon quantum dot solution is rotated to evaporate the solvent to obtain nitrogen-containing carbon quantum dots;

[0040] The above-mentioned nitrogen-containing carbon quantum dots were refluxed for 10 h in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com